Novel nano electrostatic frictional spinning device

A friction spinning, nano-scale technology, applied in the field of nano-scale electrostatic friction spinning devices, can solve the problems of low electrostatic spinning manufacturing efficiency, application field limitations, etc., to improve spinning efficiency, increase utilization rate, and expand application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

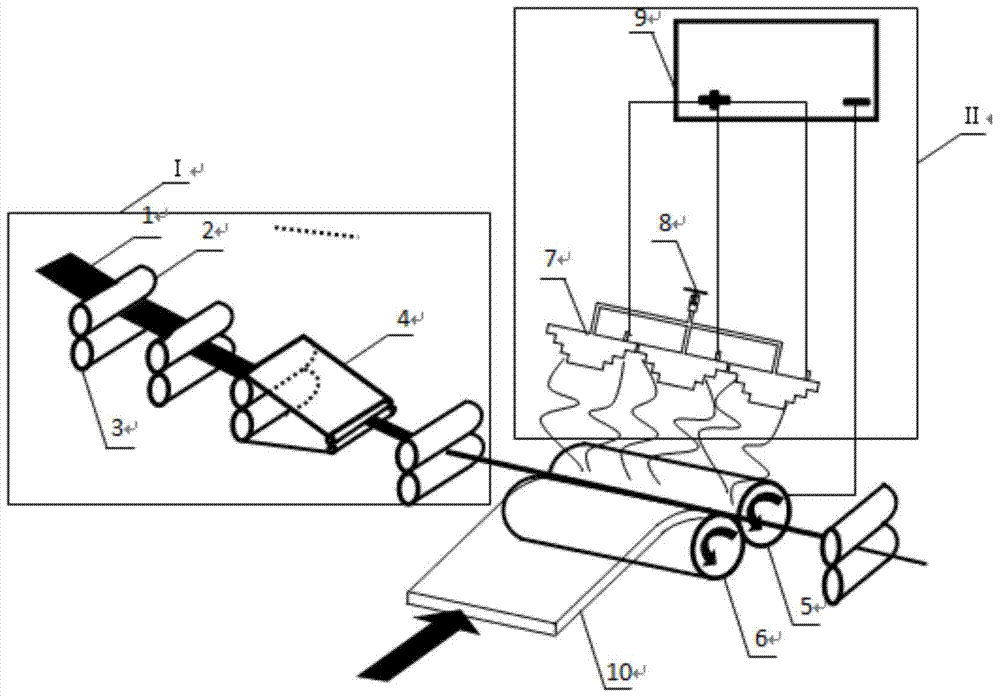

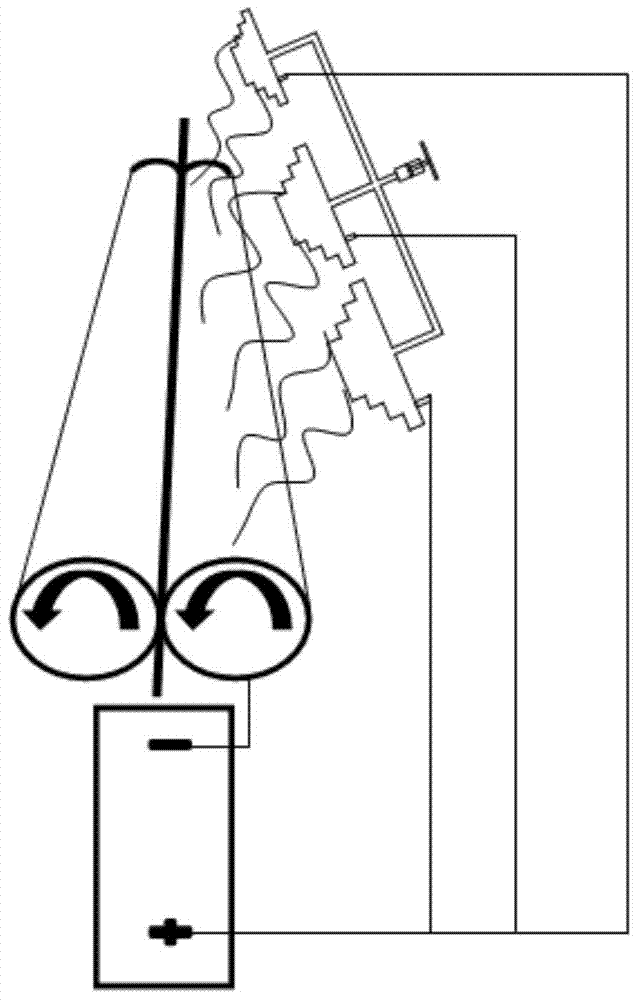

[0025] join Figure 1-Figure 2 , a new nano-scale electrostatic friction spinning device, including a drafting mechanism that sequentially drafts a fiber assembly 1, that is, four top rollers, two four rollers, three double aprons, and four rollers. Twist area, as the yarn core; the friction roller for twisting the yarn, one of which is made of metal solid material 5, and the other is made of non-metallic hollow material 6, which can rotate clockwise or counterclockwise at the same time; the metal solid friction roller is set above There is an electrospinning device for preparing nanofibers, including a pyramid-shaped spinneret 7, a barrel 8, and a voltage 9; the top of the friction roller is provided with an airflow tube 9 that can transport airflow, and squeezes the yarn in the wedge-shaped groove downward, At the same time, the non-metallic hollow friction roller pumps air to ensure that the core yarn and nanofiber can be absorbed in the wedge-shaped groove together; the fr...

Embodiment 2

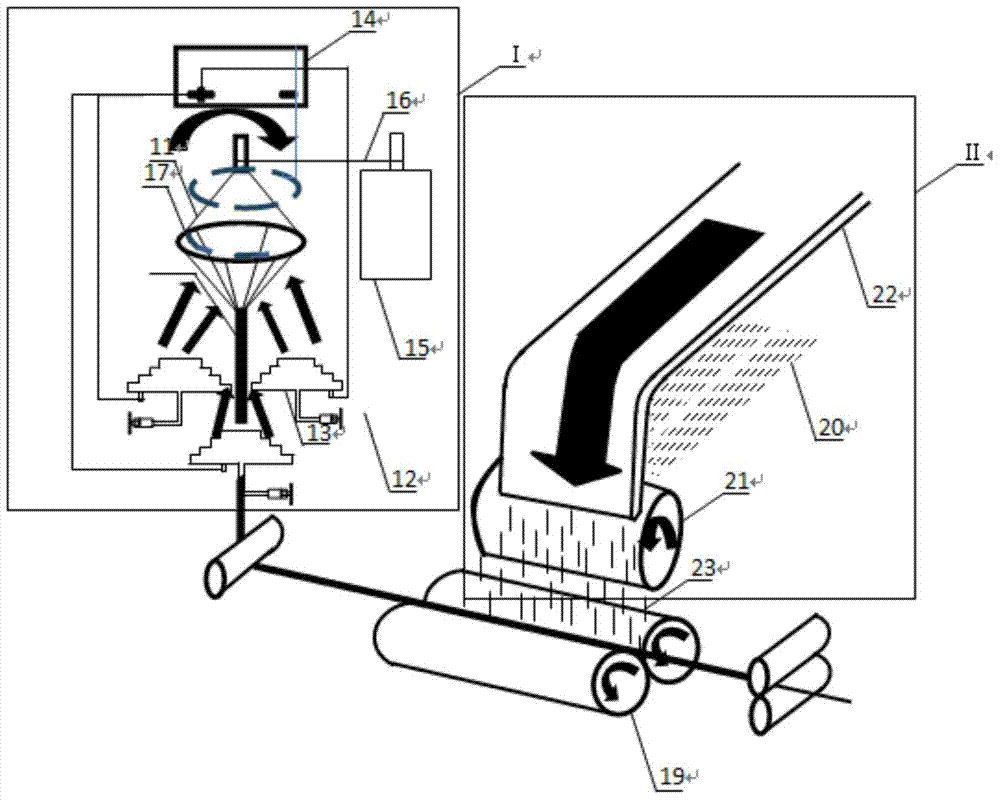

[0027] see Figure 3-Figure 4 , in the feeding zone I, an electrospinning nanofiber yarn device is set. The internal device in the section includes a horn-shaped receiver 11, a barrel 12, a pyramid-shaped spinneret 13, an electrostatic generator 14, a motor 15, and a chain 16; Electrostatic generator 14 negative pole, pyramid-shaped spinneret 13 is connected to electrostatic generator 14 positive pole, an electric field is formed between the positive and negative poles to stretch the nanofibers; a motor 15 rotating at a certain speed drives a horn-shaped receiver for collecting nanofibers 11. The horn-shaped receiver 11 rotates to form an air flow, and the nanofibers are helically deposited on the receiving ring 17 of the horn-shaped receiver 11 under the drive of the electric field force, and the deposited nanofibers are rotated and twisted under the drive of the airflow to form a nanofiber yarn 18, then introduce the friction stick 19 wedge-shaped bad. In the feeding zone ...

Embodiment 3

[0029] See Figure 4 and Figure 5 . In the feeding zone 1, traditional fibers are fed, and the cooked sliver is fed to the friction roller twisting zone along the axis through the four-roller double apron drafting device as the yarn core; in the feeding zone 2, the cooked sliver is fed and carded During the rolling process, a metal plate 24 is added between the cooked sliver and the air flow pipe, and a pyramid-shaped spinneret is added below the cooked sliver. The metal plate is connected to the negative pole, and the spinneret is connected to the positive pole. The charged nanofibers were stretched. But since the sliver is also in the middle of the electric field, the nanofibers are actually deposited under the sliver and eventually fed to the opening roller with the sliver. The metal plate is only used as an induction negative electrode to stretch the nanofiber, and is not used as a receiver. Therefore, in the feeding zone II, there are both non-nanoscale fibers and na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com