Method for low temperature precracking of thick hard difficult-to-break coal mine top board by liquid nitrogen

A liquid nitrogen, low temperature technology, used in ground mining, earthwork drilling, underground mining, etc., to achieve the effect of wide source, reducing pressure step distance and reducing the area of suspended roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

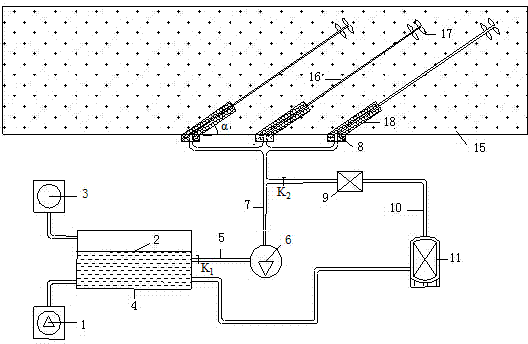

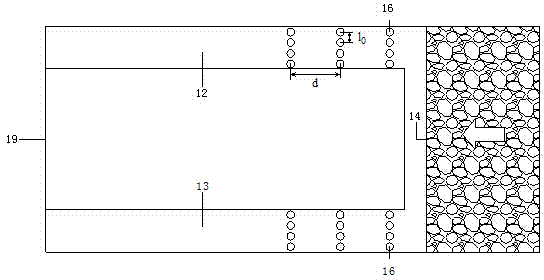

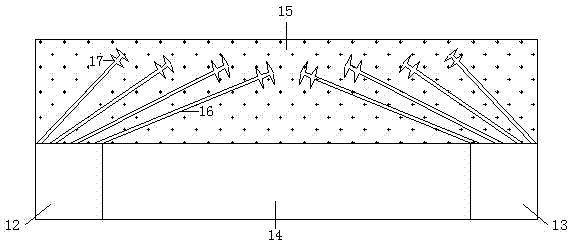

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical objectives, features and effects of the present invention, the supercritical CO 2 The thick, hard and difficult-to-break roof of a Carboniferous coal seam in a mine of the Pre-Splitting Tongmei Group will be further explained in detail.

[0038] The buried depth of the Carboniferous coal seam in a certain mine of Tongmei Group is 400-600m, and the No. 3-5 coal seam mainly mined is an extra-thick coal seam with a thickness of 14-20m. The carbonaceous coal seam roof of this ore is hard and complete, mainly composed of silt-fine sandstone and medium-coarse sandstone. When the Carboniferous coal seam is mined, the overlying thick and hard roof has a large suspended area and cannot collapse in time, which makes it more difficult to support the working face of the stope; If the gap is very large, it will accumulate a large amount of energy with the gradual advancement of the working face, and cause an instant overall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com