Low-temperature liquid storage tank cover subsystem and low-temperature liquid storage tank

A cryogenic liquid and storage tank technology, which is applied in the field of cryogenic liquid storage tank cover systems and cryogenic liquid storage tanks, can solve problems such as troublesome installation and gas loss, and achieve the effects of improved efficiency, easy installation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

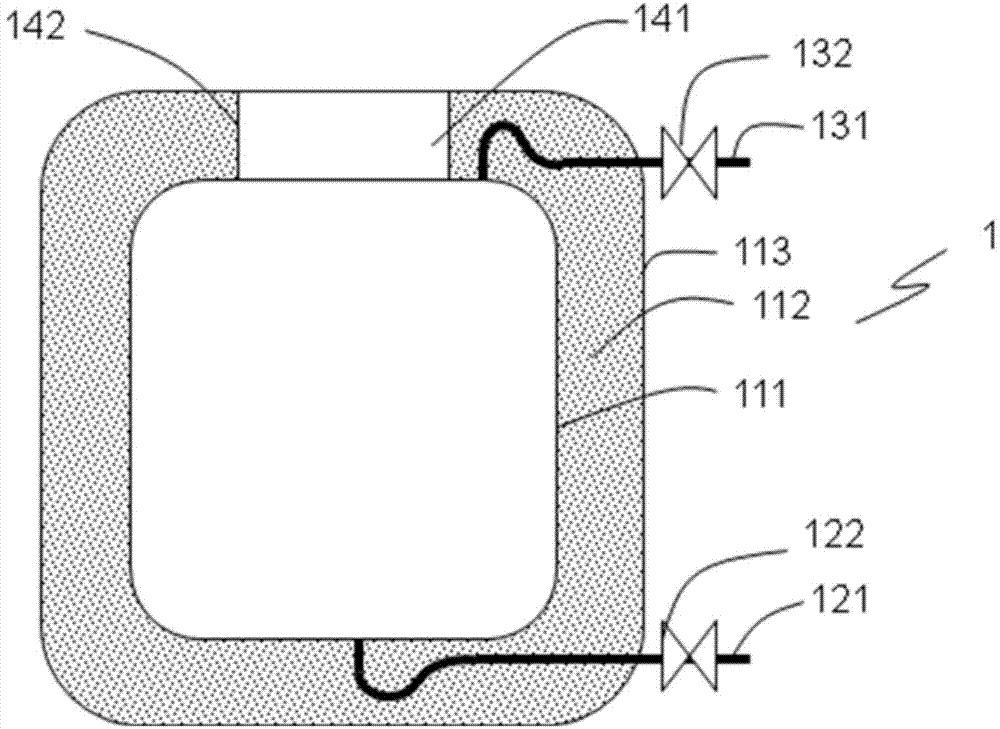

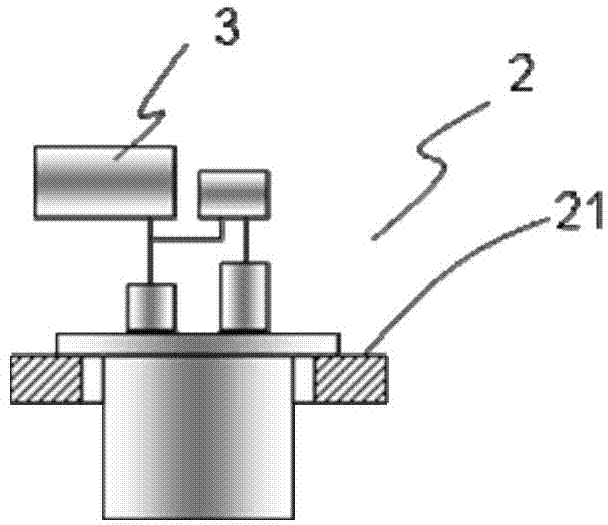

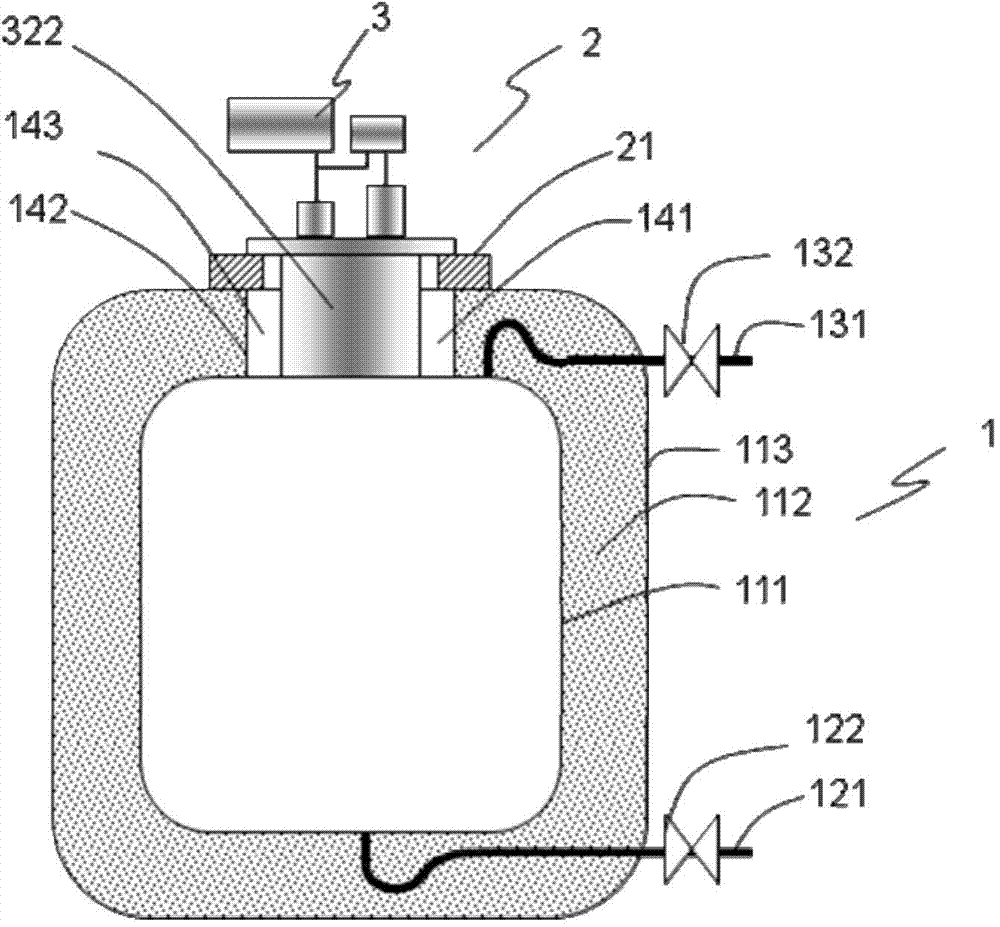

[0030] Cryogenic liquid storage tanks, such as figure 1 , figure 2 , image 3 As shown, it includes a cryogenic liquid storage tank body 1 and a cover system 2 .

[0031] Such as figure 1 , image 3 As shown, the cryogenic liquid storage tank body 1 is composed of a storage tank inner shell 111, a storage tank outer shell 113 and a storage tank insulation material 112 filled between the storage tank inner shell 111 and the storage tank outer shell 113. On the cryogenic liquid storage tank body 1 A storage tank liquid inlet pipe 121 and a storage tank steam outlet pipe 131 are provided. The storage tank liquid inlet pipe 121 is provided with a storage tank liquid inlet valve 122 , and the storage tank outlet pipe 131 is provided with a storage tank steam outlet valve 132 . The storage tank insulation material 112 is sandwiched between the storage tank inner shell 111 and the storage tank outer shell 113 to reduce heat leakage. The upper part has a storage tank opening 141...

Embodiment 2

[0042] The difference from Embodiment 1 is that the refrigerator cover 322 is made of low thermal conductivity material such as foam material, such as Figure 7 shown.

Embodiment 3

[0044] The difference from Embodiment 1 is that no freezer cover is set in the low temperature part 30, such as Figure 8 As shown, a large heat leakage loss may occur at this time, which may cause dew and ice on the tank cover and cause corrosion problems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com