Natural gas hydrate synthesis and mechanical testing integrated pressure chamber

A hydrate and natural gas technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of troublesome sample loading, capillary blockage, low pressure resistance, etc., and achieves convenient installation, simple operation, and strong pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments.

[0022] Gas hydrate is an enveloping crystal formed by the interaction of gas or volatile liquid with water. Gas hydrate needs to exist at high pressure and low temperature, so its physical properties need to be measured in situ under low temperature and high pressure conditions.

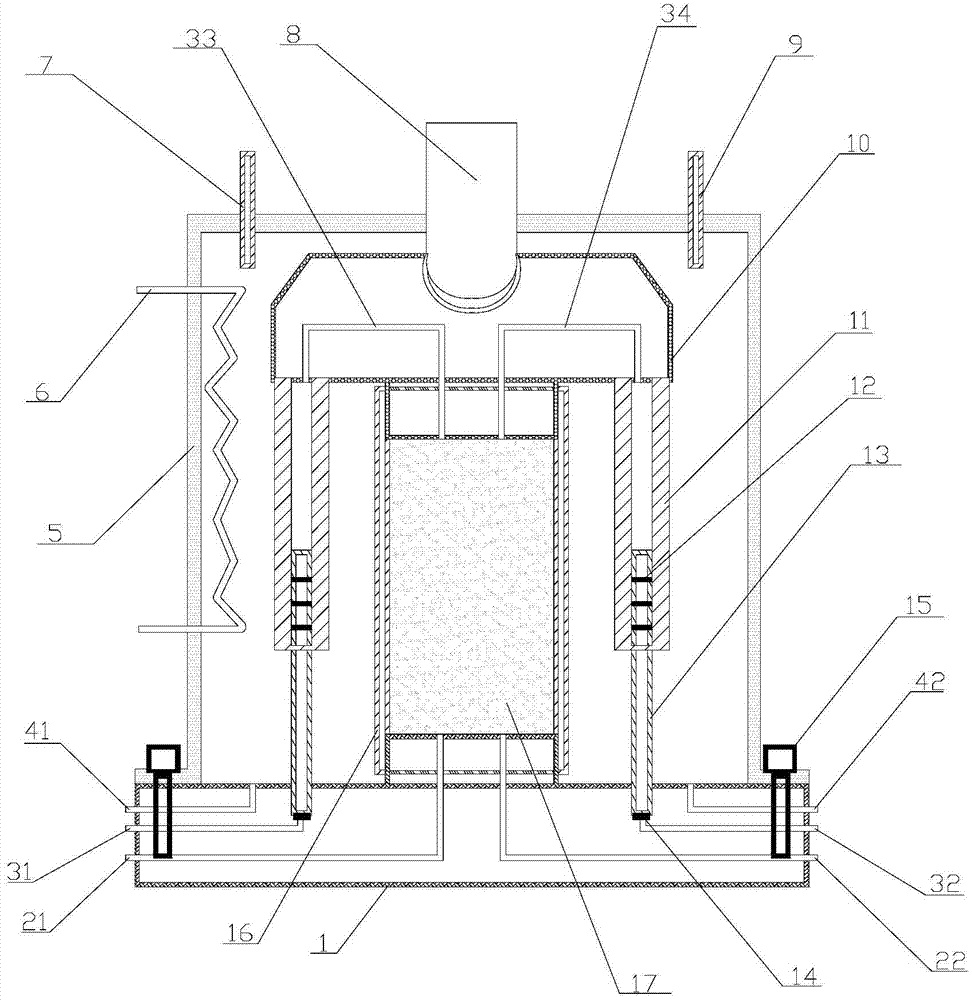

[0023] see figure 1 As shown, the integrated pressure chamber is suitable for in-situ synthesis and decomposition of natural gas hydrate in sediments and its mechanical properties are tested using a triaxial system. The pressure chamber includes a base 1, an upper shell 5, a force transmission shaft 8, an end cover 10, a telescopic sleeve (composed of an outer tube 11, a sealing ring 12 and an inner tube 13), a built-in heat exchanger 6, and a temperature sensor for temperature measurement 9 and a pressure sensor 7 for pressure measurement. The entire pressure chamber is a special pressure vesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com