Polycrystalline diamond construction & method of making

A superhard polycrystalline and polycrystalline superhard technology, which is applied in the manufacture of tools, earth drilling, metal processing equipment, etc., can solve the problems of difficult and expensive processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

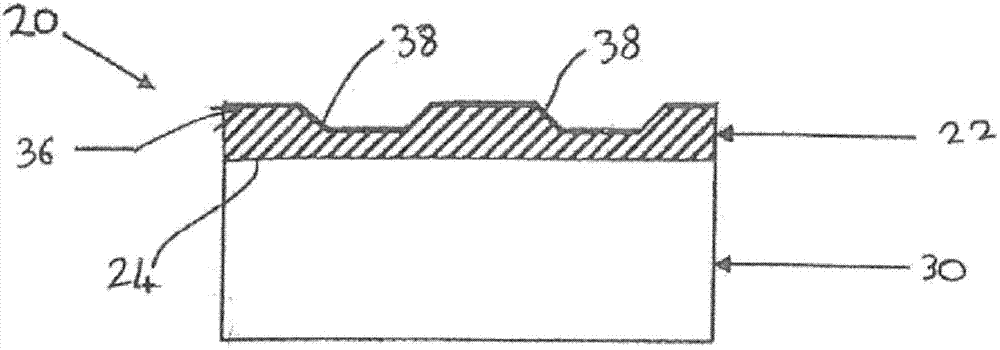

[0094] This non-limiting example shows a method of forming surface topology during sintering.

[0095] A surface topology can be tailored to the needs of a given drilling or cutting application and is related to the cutter configuration or the shape of the machine tool insert. A cobalt cemented carbide substrate body may be provided and a ceramic plug may be provided having a surface with a surface topology that complements (eg reverses) the desired surface topology of the cutter or machine tool insert. A pre-compressed assembly may be prepared by forming a mass of diamond particles into a polymer against the surface of a substrate, and encapsulating the assembly in an enclosure formed, for example, of alumina or other ceramic material. The surface of the ceramic plug with the desired surface topology imparted to the diamond body during sintering is placed in contact with the diamond particles. The pre-compressed assembly is subjected to an ultra-high pressure of at least abo...

example 2

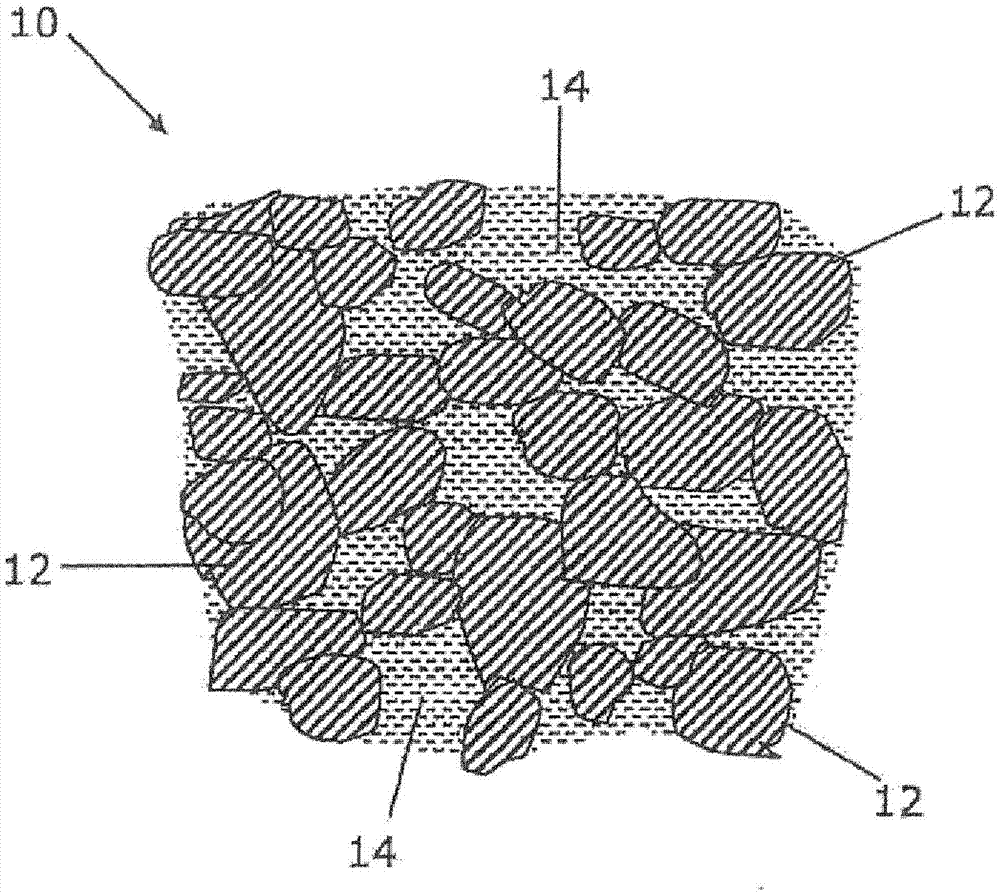

[0097] Some submicron cobalt powder, sufficient to obtain 2% by weight in the final diamond mixture, was initially agglomerated down in the methanol suspension ball milled with tungsten carbide media for one hour. Fine-grained diamond powder with an average particle size of 2 micrometers was then added to the suspension, which amounted to 10% by weight in the final mixture. Additional milling media was introduced and methanol was further added to obtain a proper suspension; and further milled for one hour. Coarse-grained diamonds with an average particle size close to 20 microns were added next and made up 88% by weight of the final mixture. The suspension was again further supplemented with methanol and grinding media, and then further ground for 2 hours. The suspension was removed from the ball mill and dried to obtain a diamond powder mixture.

[0098] The diamond powder mixture is then placed into a suitable HPHT vessel adjacent to a substrate of tungsten carbide and sin...

example 3

[0101] Some submicron cobalt powder, sufficient to obtain 2.4% by weight in the final diamond mixture, was initially agglomerated down in the methanol suspension ball milled with tungsten carbide media for one hour. Fine-grained diamond powder with an average particle size of 2 micrometers was then added to the suspension to give a total of 29.3% in parts by weight in the final mixture. Additional grinding media was introduced and methanol was further added to obtain a proper suspension; and this was further ground for one hour. Coarse-grained diamonds with an average particle size close to 20 microns were added next to make up 68.3% by weight of the final mixture. The suspension was again further supplemented with methanol and grinding media, and then further ground for 2 hours. The suspension is removed from the ball mill and dried to obtain a diamond powder mixture

[0102] The diamond content of the sintered diamond structure is greater than 90% by volume and the distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com