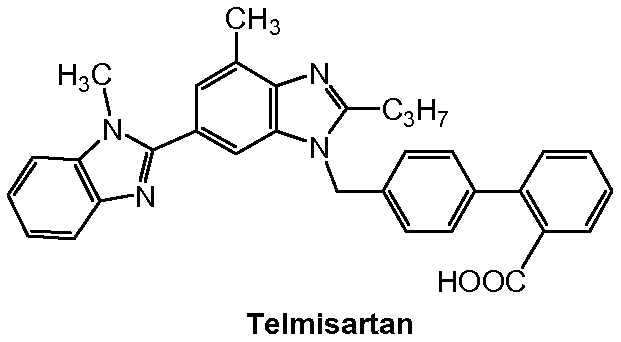

Method for preparing telmisartan and its intermediate

A compound and reaction technology, applied in the field of preparation of intermediates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

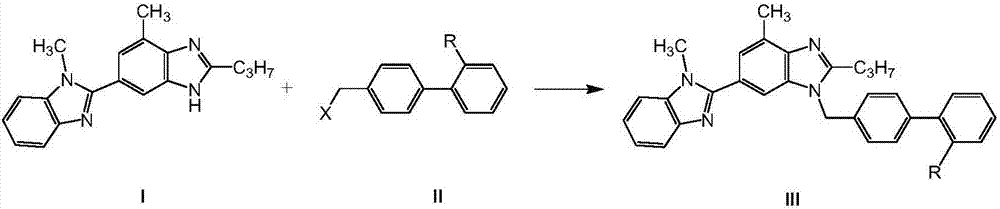

Problems solved by technology

Method used

Image

Examples

Embodiment 1

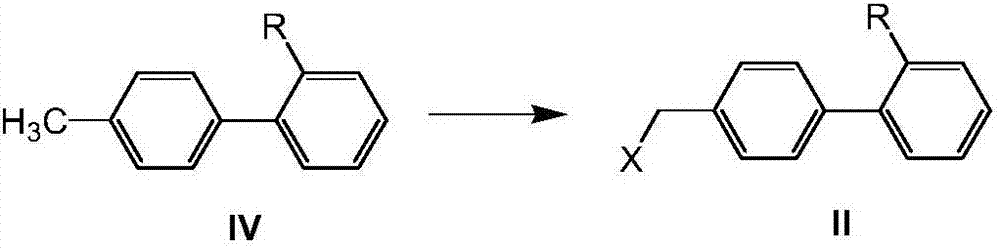

[0103] Example 1: Preparation of 4'-chloromethylbiphenyl-2-carboxylic acid (II, R=COOH, X=CI)

[0104] Add 4′-methylbiphenyl 2-carboxylic acid (IV) (10 g, 0.047 mol), azobisisobutylcyanide (AIBN) (0.11 g, 1.5 mol%) into chlorobenzene (35 mL), stir, Heat to 90°C, slowly add SO 2 Cl 2 (3.8mL, 0.047mol) of chlorobenzene solution (15mL), after the dropwise addition, stir for 1 hour, and TLC detects that the reaction is over; the reaction solution is naturally cooled to room temperature, and solids are precipitated, then cooled in an ice bath for 1 hour, and suction filtered , the obtained filtrate was washed with toluene (10 mL×2), and dried to obtain white granular solid II (9.5 g, yield 82%). 1 H NMR (300 MHz, DMSO-d6): 12.79 (s, 1H, OH), 7.21-7.75 (m, 8H, ArH), 4.81 (s, 2H, CH2), MS: 246.1.

Embodiment 2

[0105] Example 2: Preparation of 4'-chloromethylbiphenyl-2-carboxylic acid (II, R=COOH, X=Cl)

[0106] Add 4′-methylbiphenyl 2-carboxylic acid (IV) (10 g, 0.047 mol), azobisisobutylcyanide (AIBN) (0.11 g, 1.5 mol%) into chlorobenzene (70 mL), stir, Heated to 80° C., added trichloroisocyanuric acid (10.9 g, 0.047 mol), stirred and reacted for 12 hours, and insoluble matter was filtered off by heat; the reaction solution was naturally cooled to room temperature, and solids were precipitated, and the resulting filtrate was washed with toluene ( 10mL×2), dried to obtain white granular solid II (6g, yield 52%).

Embodiment 3

[0107] Example 3: Preparation of 4'-chloromethylbiphenyl-2-carboxylic acid (II, R=COOH, X=Cl)

[0108] 4'-methylbiphenyl 2-carboxylic acid (IV) (10 g, 0.047 mol) was dissolved in dichloromethane (150 mL), benzoyl peroxide (0.23 g, 2 mol%) was added, and 1.1 equivalent of chlorine was added, The reaction was stirred for 12 hours; saturated aqueous sodium bicarbonate solution was added to the reaction solution for extraction, the organic layer was separated, and the solvent was evaporated to dryness to obtain off-white solid II (6 g, yield 52%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com