All-solid ion secondary cell

A secondary battery and all-solid technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem of short ion conduction distance and achieve the effect of increasing energy density and output power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

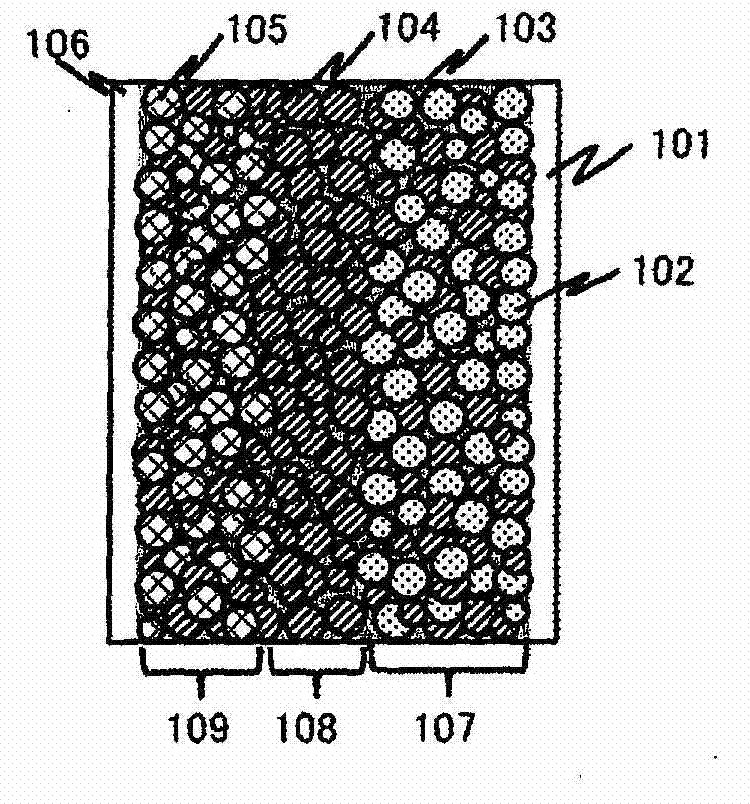

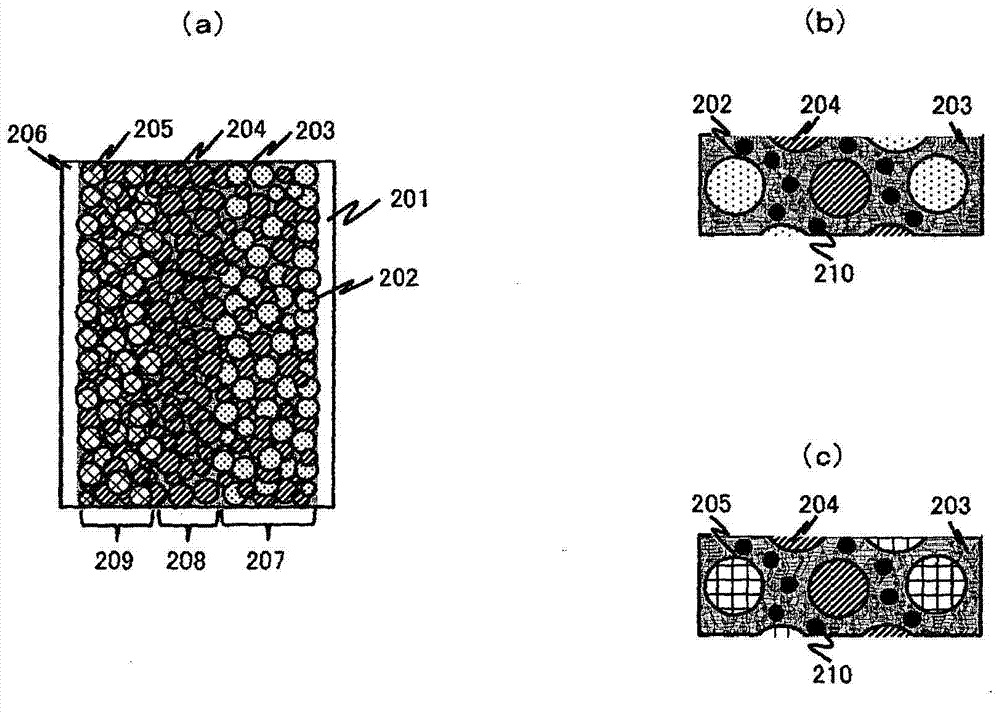

Method used

Image

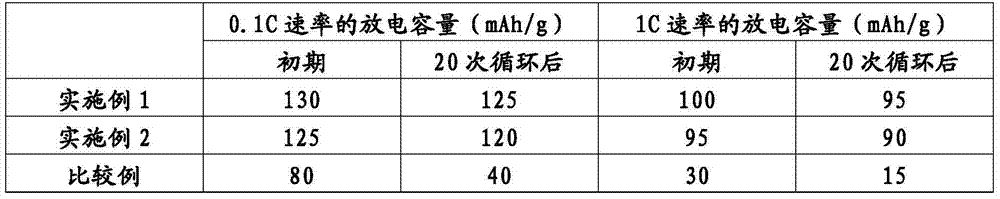

Examples

Embodiment 1

[0043]

[0044] Vanadium oxide glass A having ion conductivity and ferroelectricity, and vanadium oxide glass B having only ion conductivity were prepared. As a raw material, vanadium pentoxide (V 2 o 5 ), phosphorus pentoxide (P 2 o 5 ), tellurium dioxide (TeO 2 ), ferric oxide (Fe 2 o 3 ), barium carbonate (BaCO 3 ), titanium dioxide (TiO 2 ). As the raw material composition of glass A, the molar ratio of various raw materials is: V 2 o 5 :P 2 o 5 :TeO 2 :Fe 2 o 3 :TiO 2 :BaCO 3 =36.2:10:23.1:7.7:11.5:11.5. In addition, as the raw material composition of glass B, the molar ratio of various raw materials is: V 2 o 5 :P 2 o 5 :TeO 2 :Fe 2 o 3 =55:14:22:9. These raw material powders were put into a platinum crucible, and heated at 1100°C for 1 hour in an electric furnace. Also, during heating, stir the raw materials in the platinum crucible to achieve uniformity. Then, the platinum crucible was taken out from the electric furnace, spread on a stainl...

Embodiment 2

[0061]

[0062] Two types of ion-conductive vanadium oxide glasses with different softening points were produced. As a raw material, vanadium pentoxide (V 2 o 5 ), phosphorus pentoxide (P 2 o 5 ), tellurium dioxide (TeO 2 ) powder, ferric oxide (Fe 2 o 3 ). As the raw material composition of glass A with a high softening point, the molar ratio of various raw materials is V 2 o 5 :P 2 o 5 :TeO 2 :Fe 2 o 3 = 47:13:30:10. In addition, as the raw material composition of glass B with a low softening point, the molar ratio is V 2 o 5 :P 2 o 5 :TeO 2 :Fe 2 o 3 =55:14:22:9. These raw material powders were put into a platinum crucible, and heated at 1100°C for 1 hour in an electric furnace. Also, stir during heating to make the raw materials in the platinum crucible uniform. Then, the platinum crucible was taken out from the electric furnace, spread on a stainless steel plate preheated to 150°C, and cooled naturally to obtain vanadium oxide glass. The softenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com