Novel wet type ship waste gas comprehensive treatment method and device

A technology for comprehensive treatment and exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

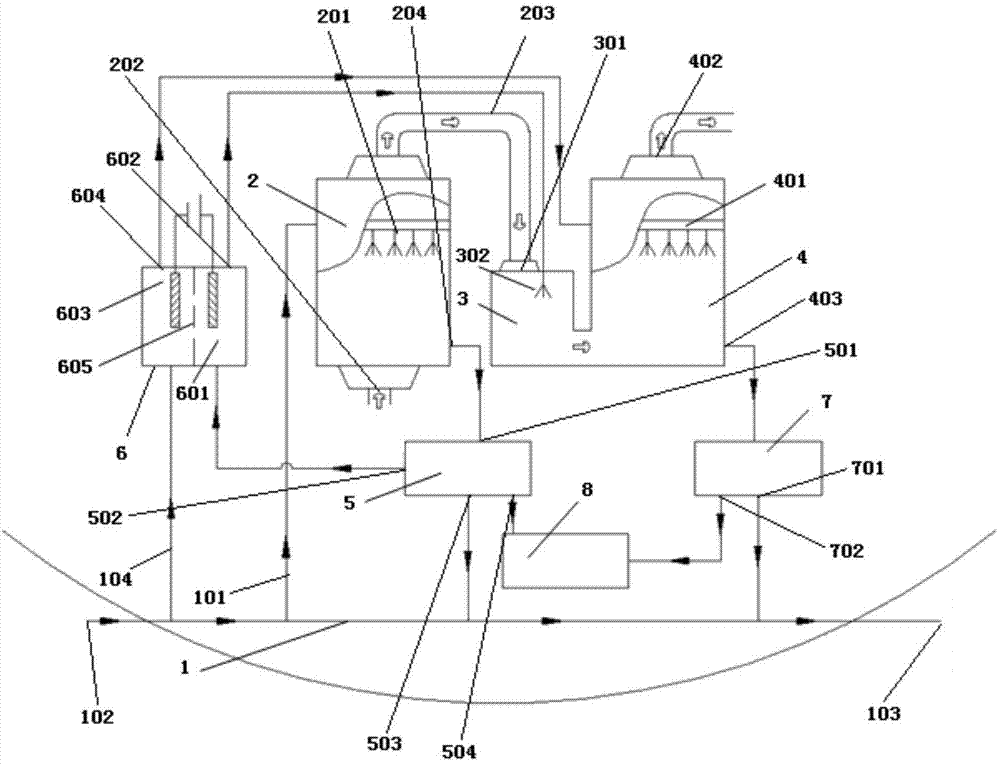

Image

Examples

Embodiment Construction

[0039] A novel wet ship exhaust gas comprehensive treatment method has the following steps:

[0040] 1) The exhaust gas emitted by marine diesel engines is mixed with natural seawater to remove SO in the exhaust gas X and PM, to obtain a waste liquid and a purified waste gas,

[0041] Natural seawater reacts chemically with the waste gas as shown below:

[0042] SO 2 (g)→SO 2 (l),

[0043] SO 2 (l)+H 2 O→HSO 3 - +H3O + ,

[0044] HSO 3 - +H 2 O→SO 3 2- +H 3 o + ,

[0045] 2SO 3 2- +O 2 →2SO 4 2- ,

[0046] The SOx and PM in the exhaust gas are washed and removed by natural seawater, and the pH value of the obtained primary waste liquid changes from about 8 to an acidic range of 2-5, and contains more impurities such as sulfite and particulate matter ;

[0047] 2) Natural seawater enters the cathode tank of the diaphragm electrolysis device and reacts with the cathode to obtain a strongly reducing and strongly alkaline solution; after the primary waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com