Full-band high-precise machining method for aspheric surface optical element

A processing method and aspheric technology, which are used in optical surface grinders, metal processing equipment, control of workpiece feed movement, etc. The effect of improving the quality of optical surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

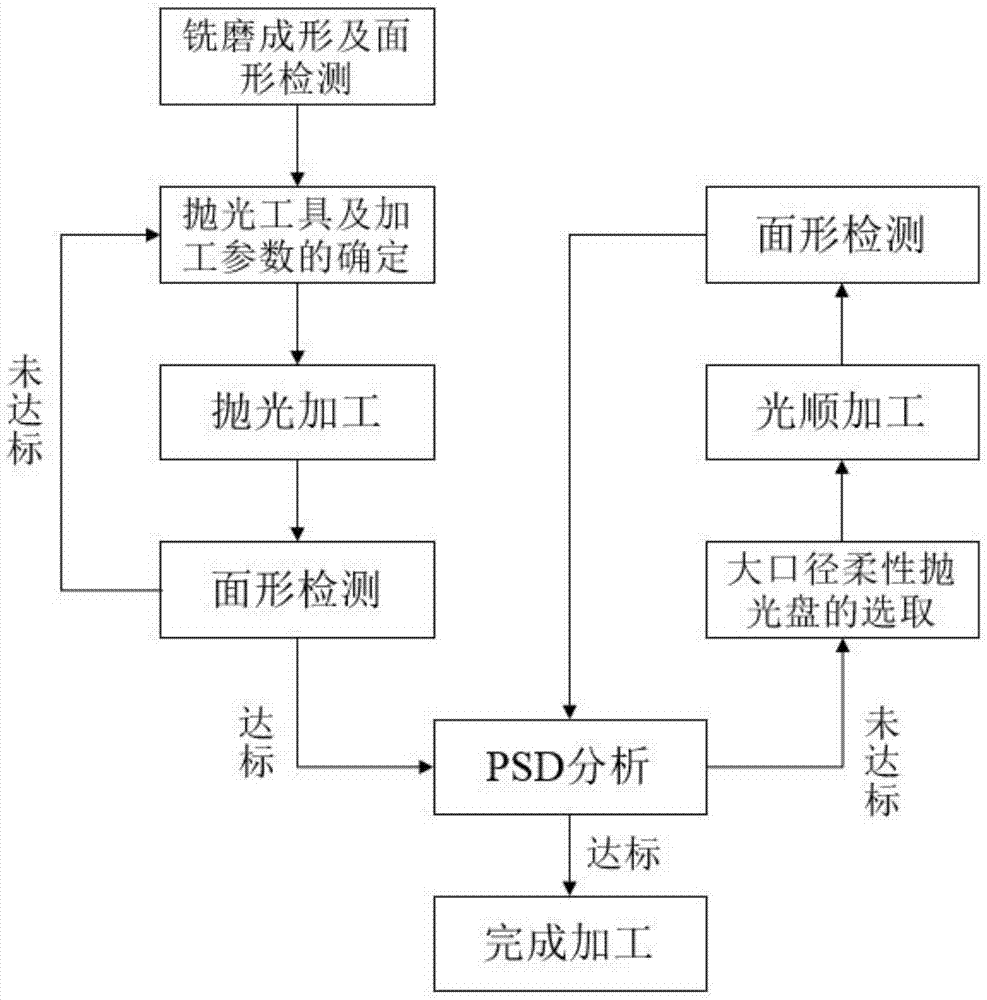

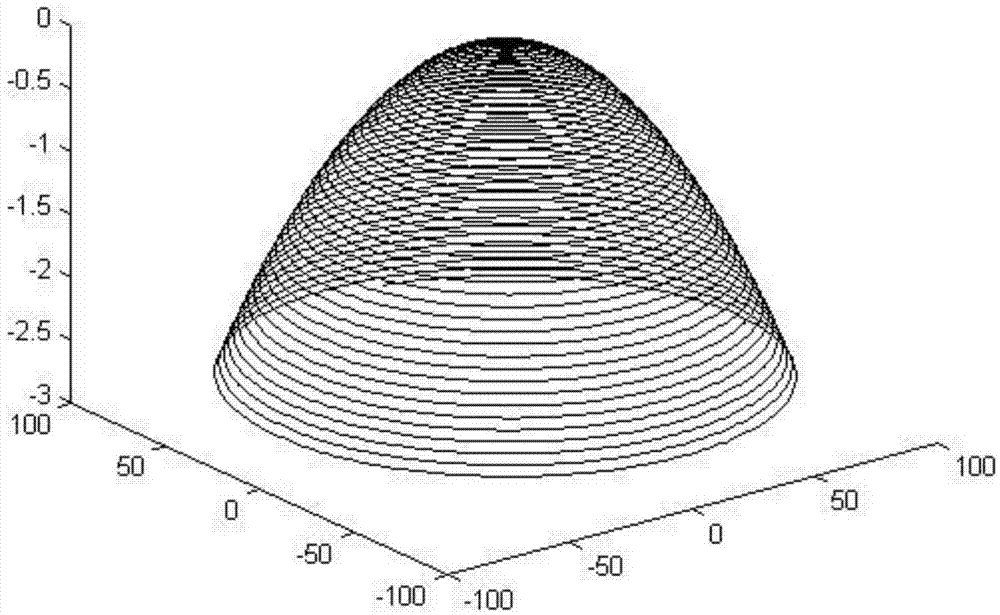

[0020] The processing object of the processing method in this embodiment is a convex aspheric mirror with a diameter of 200 mm and a vertex curvature radius of 1700 mm. refer to figure 1 , the operation steps of the full-band high-precision aspheric surface processing method in this embodiment are as follows:

[0021] Step 1) After the aspherical element to be processed is milled and formed, an interferometer is used to measure the shape error of the aspheric surface at this time.

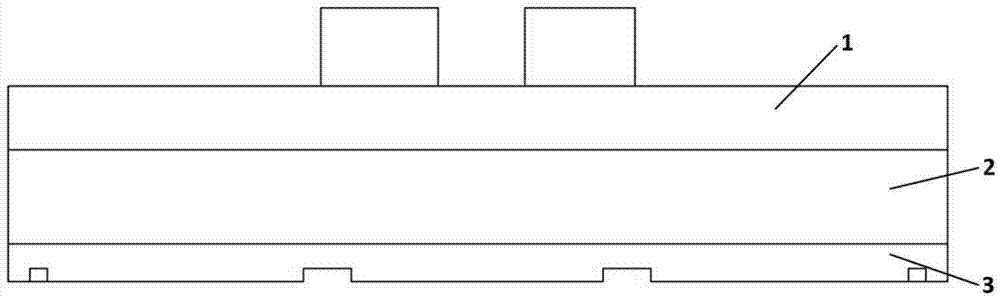

[0022] Step 2) According to the measured surface shape error data, select a flexible polishing small tool with an aperture size not larger than 1 / 4 of the aspherical surface diameter, and then select the optimal Gaussian-like removal function, and thus determine the processing parameters of CNC machine tools, including revolution speed, eccentricity, positive pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com