An overprinting method using a rubber-coated center roller as a printing roller

A technology of center roller and printing roller, applied in printing, printing device and other directions, can solve the problems of poor control accuracy, poor printing continuity and stability, low overprinting accuracy and speed, etc., to prevent accidental deletion and ensure stability and reliability. readability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

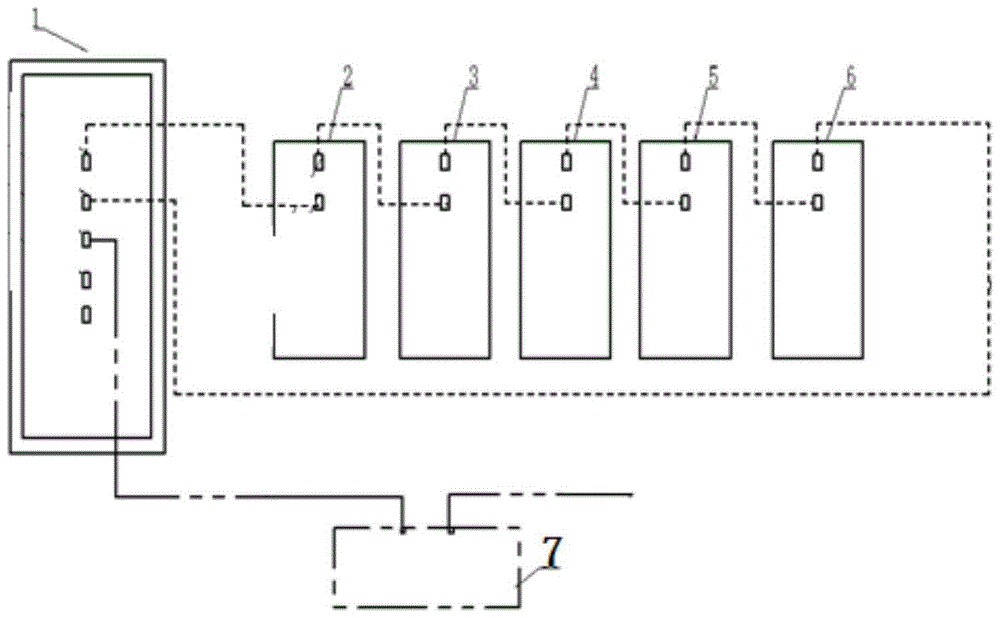

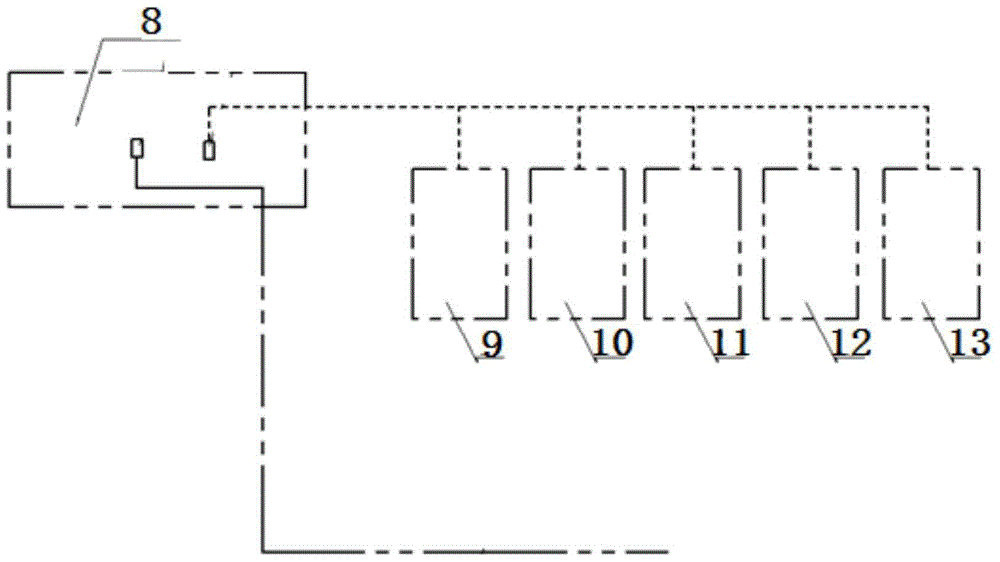

[0025] A kind of overprinting method that the present invention uses rubber-covered center roller as printing roller, based on the following control system, as figure 1 , figure 2 As shown, the specific structure of the control system is as follows: the PLC controller 8 is connected with the discharging frequency converter 9 of the discharging part, the discharging traction frequency converter 10 of the discharging traction part, the cooling frequency converter 11 of the cooling part, and the The material receiving traction inverter 12 is connected with the material receiving inverter 13 in the material receiving part, and the printing work of the whole machine is guaranteed by controlling the orderly operation of the feeding part, feeding traction part, water cooling part, receiving material pulling part and receiving part In an orderly ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com