Synthetic method for self-luminous polymer microsphere

A synthesis method and polymer technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve broad application prospects, stable performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

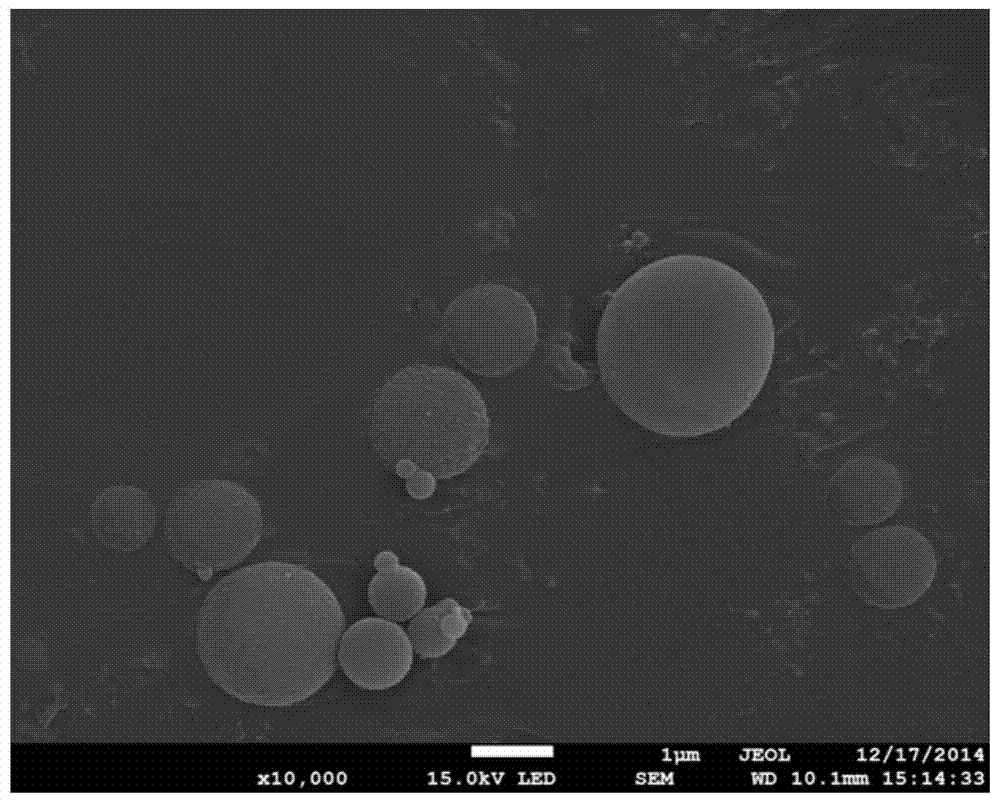

[0014] The invention provides a synthetic method of self-luminous polymer microspheres, which comprises the following steps:

[0015] A. Provide polyethyleneimine aqueous solution and emulsifier solution, and mix the two to obtain emulsion;

[0016] B. At 15-25°C, add a crosslinking agent solution to the emulsion obtained in step A, and stir to obtain an orange-red emulsion;

[0017] C. Remove the oil phase and excess crosslinking agent from the emulsion obtained in step B to obtain self-luminous polymer microspheres.

[0018] Polyethyleneimine is a water-soluble high molecular polymer. Although it is also soluble in polar organic solvents such as ethanol and acetone, if an organic solvent is used to dissolve polyethyleneimine to form its organic solution, the crosslinking agent and polyethyleneimine will Insufficient amine binding may form broken microspheres, and aqueous solutions are safer, more environmentally friendly and more cost-effective than organic solutions.

[0...

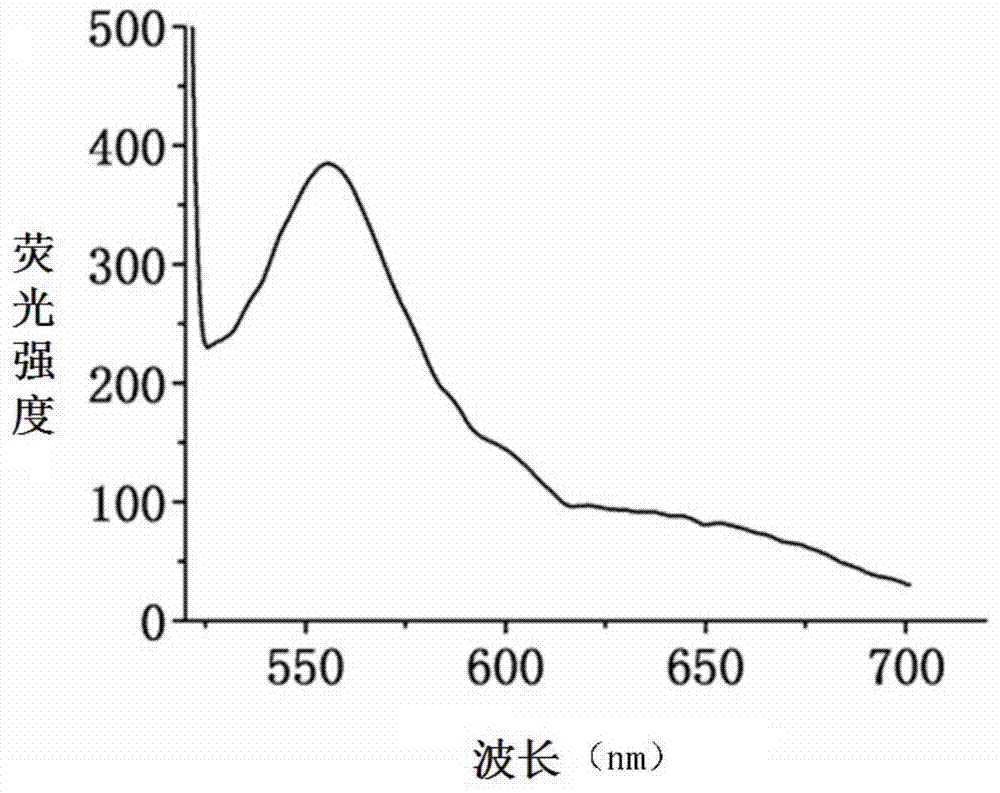

Embodiment 1

[0027] Dissolve 2mL of PEI aqueous solution with a mass concentration of 25% and a molecular weight of 1800, 2mL of liquid paraffin and 0.2g of emulsifier span-20 in a sample bottle, and emulsify at high speed for 2 minutes;

[0028] At 15-25°C, add 2 mL of glutaraldehyde aqueous solution with a mass concentration of 25% to the sample bottle dropwise, and stir magnetically to obtain an orange-red emulsion;

[0029] The orange-red emulsion was washed and centrifuged with 2 mL of isopropanol, 2 mL of anhydrous ether, and 2 mL of deionized water, respectively, to obtain self-luminescent polymer microspheres.

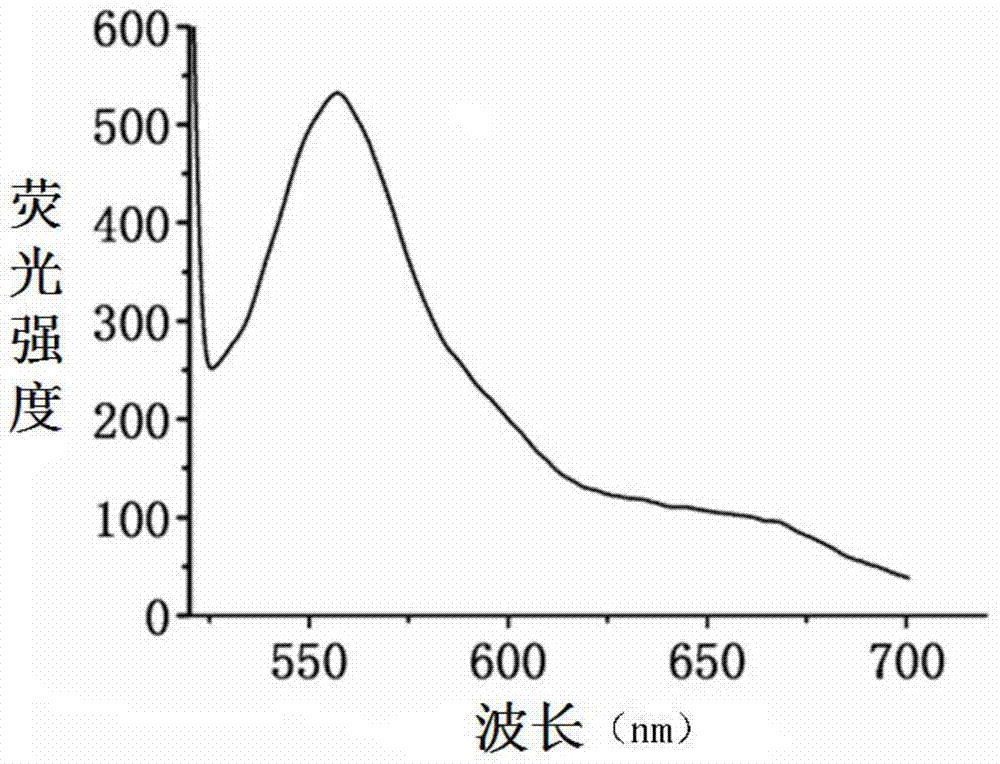

Embodiment 2

[0031] Dissolve 4 mL of PEI aqueous solution with a mass concentration of 25% and a molecular weight of 6000, 4 mL of liquid paraffin and 0.4 g of emulsifier span-60 in a sample bottle, and emulsify at high speed for 4 minutes;

[0032] At 15-25°C, add dropwise 4 mL of 30% isocyanate ethanol solution into the sample bottle, and magnetically stir to obtain an orange-red emulsion;

[0033] The orange-red emulsion was washed and centrifuged with 4 mL of isopropanol, 4 mL of anhydrous ether, and 4 mL of deionized water, respectively, to obtain self-luminescent polymer microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com