One-component epoxy adhesive used for bonding LED backlight modules LENS

A technology of epoxy adhesive and backlight module, which is applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problem of insufficient moisture and heat aging resistance of single-component epoxy, and achieve the effect of excellent moisture and heat aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

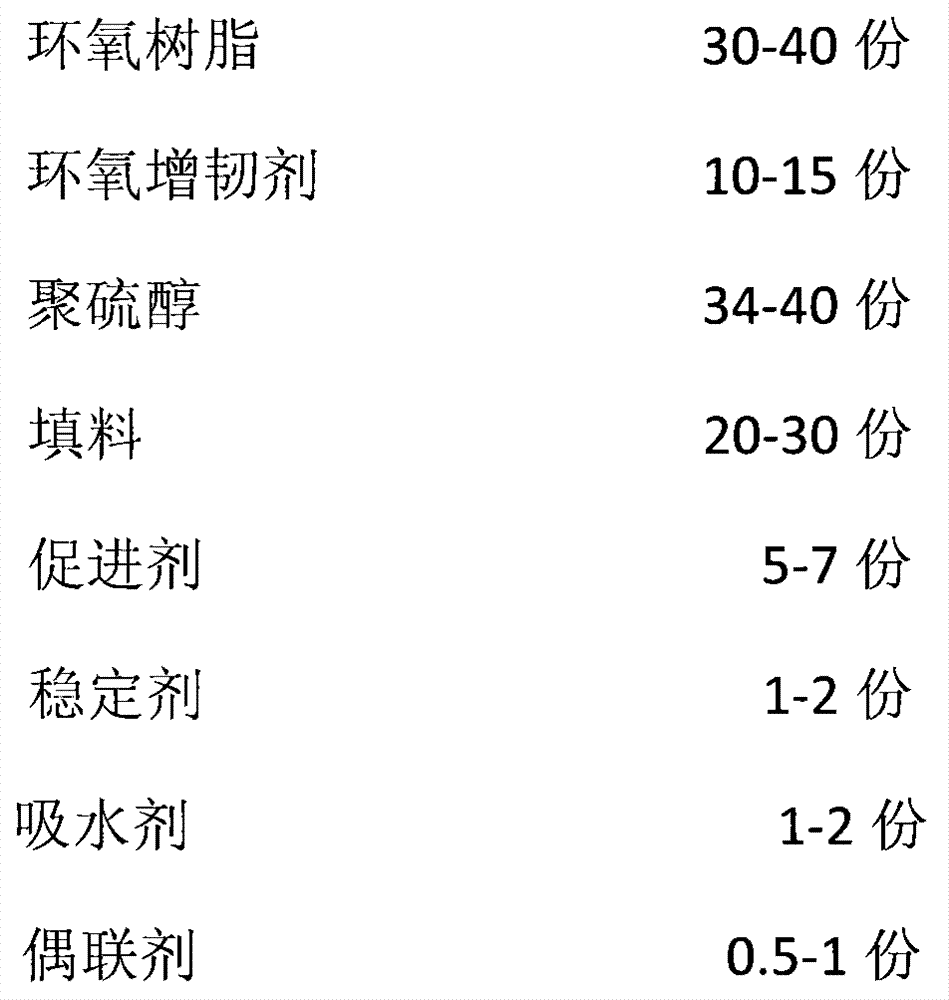

Method used

Image

Examples

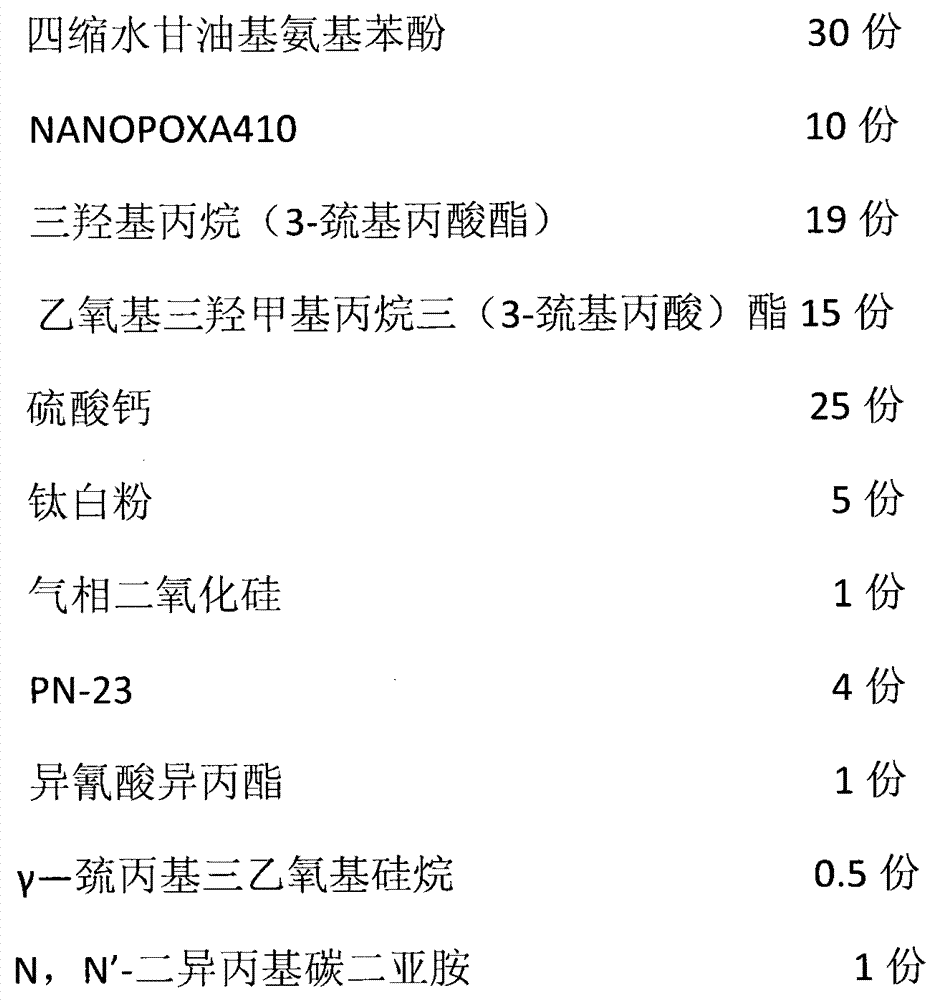

Embodiment 1

[0018] Preparation:

[0019]

[0020] Preparation:

[0021] Accurately weigh various raw materials according to the proportion of the formula. acid) ester, γ-mercaptopropyltriethoxysilane, N, N'-diisopropylcarbodiimide, mix evenly, then add calcium sulfate (add in three times) mix evenly, and then add fumed silica , titanium dioxide, isopropyl isocyanate, and PN-23 are mixed evenly (control temperature is 20-35 degrees), and the material is discharged after 30 minutes of full vacuum.

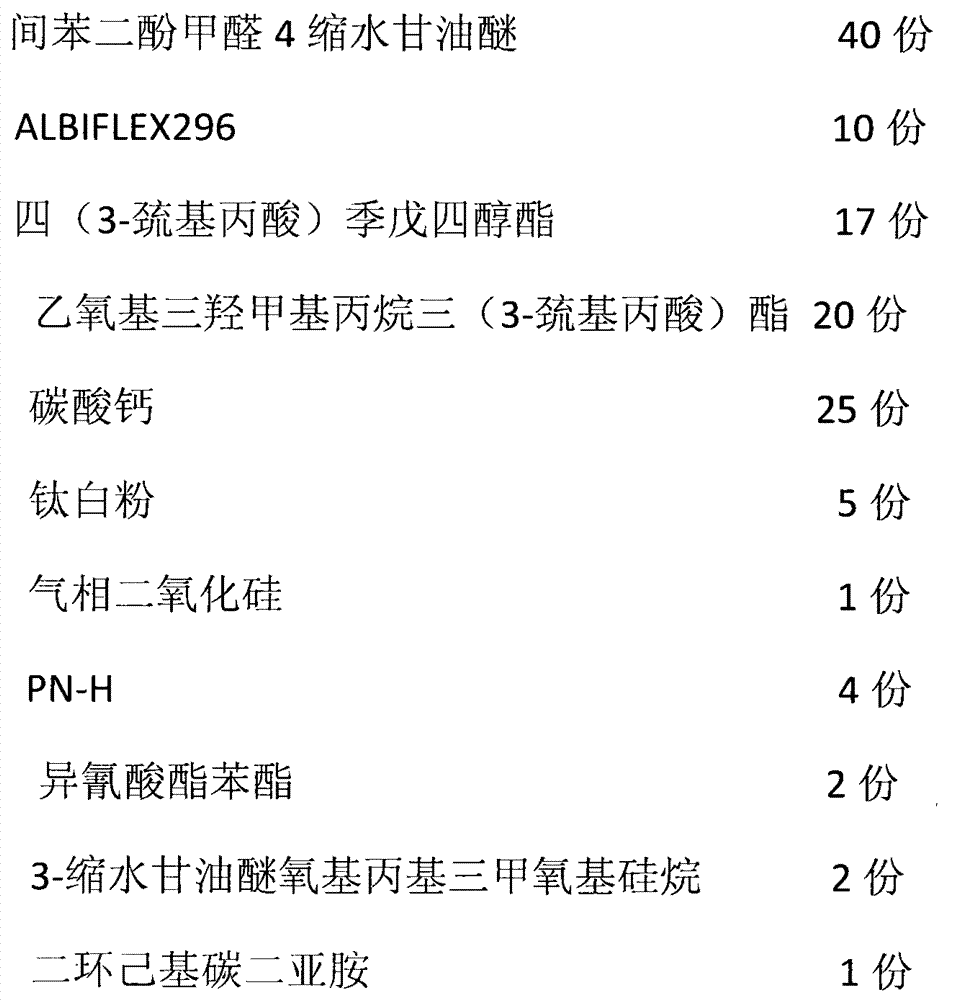

Embodiment 2

[0023]

[0024] Preparation:

[0025] Accurately weigh various raw materials according to the proportion of the formula. ) ester, 3 glycidyl ether oxypropyl trimethoxysilane, dicyclohexyl carbodiimide and mix evenly, then add calcium carbonate (add in three times) mix evenly, then add fumed silica, isocyanate benzene Ester and PN-H are mixed evenly (control temperature is 20-35 degrees), and the material is discharged after 30 minutes of full vacuum.

Embodiment 3

[0027]

[0028] Preparation:

[0029] Accurately weigh various raw materials according to the proportion of the formula. Glyceryl ether oxypropyl trimethoxysilane, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride are mixed evenly, then calcium carbonate is added (adding in three times) and mixed evenly, then Add gas-phase silica, benzyl isocyanate, and PN-H in sequence and mix well (control the temperature at 20-35 degrees), and discharge the material after full vacuum for 30 minutes.

[0030] Table 1 is the performance test result after curing of the listed embodiment and the comparative example of similar products on the market, and the test result shows:

[0031] The invention has excellent anti-aging performance and can meet the needs of LED backlight module LENS bonding.

[0032] Table 1

[0033]

[0034] Note: The shear strength is tested according to the standard of GB / T7124-1986.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com