Double input planetary gear main reducer

A main reducer, planetary gear carrier technology, applied in the direction of gear transmission, belt/chain/gear, transportation and packaging, etc., can solve problems such as inapplicability and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

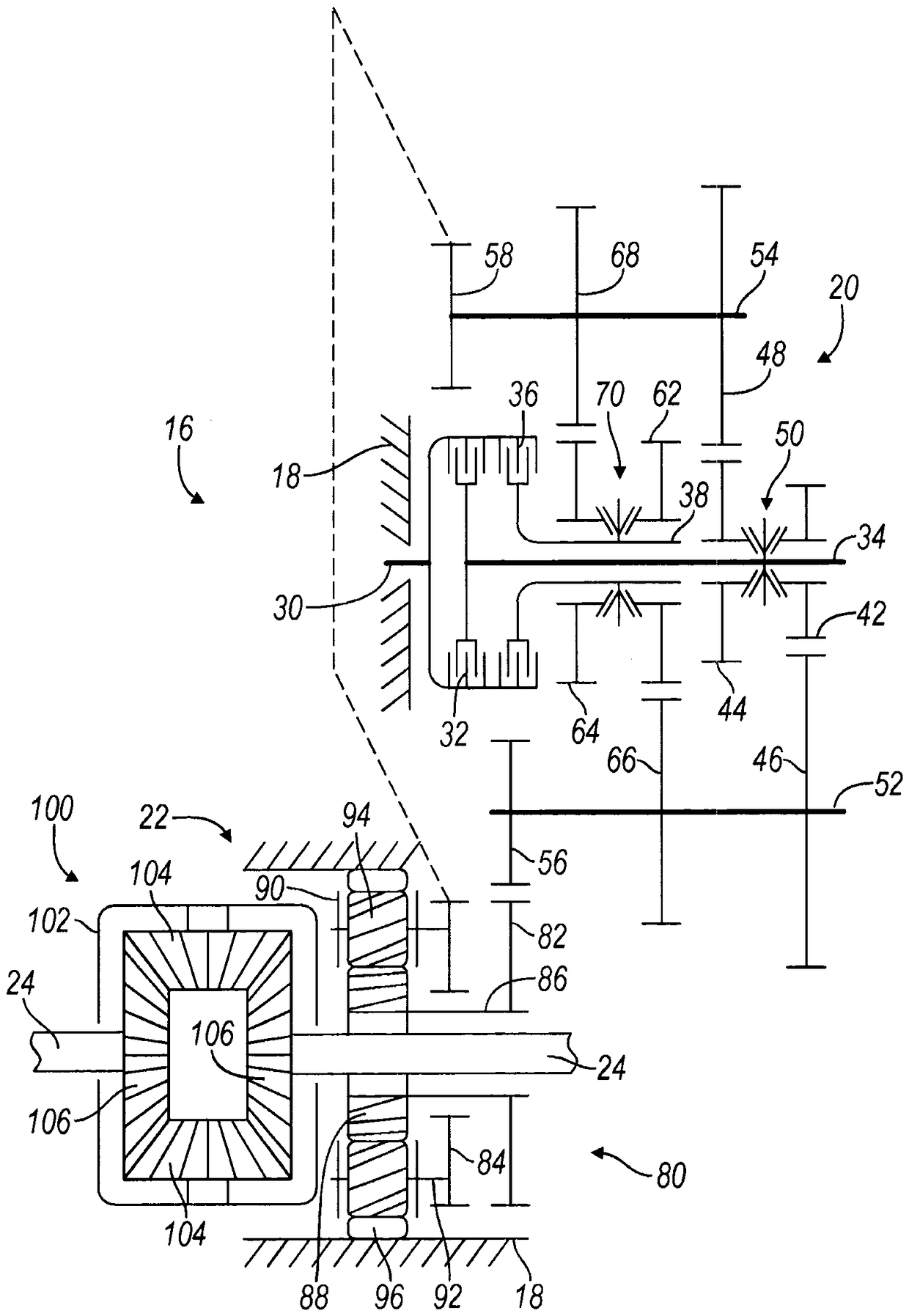

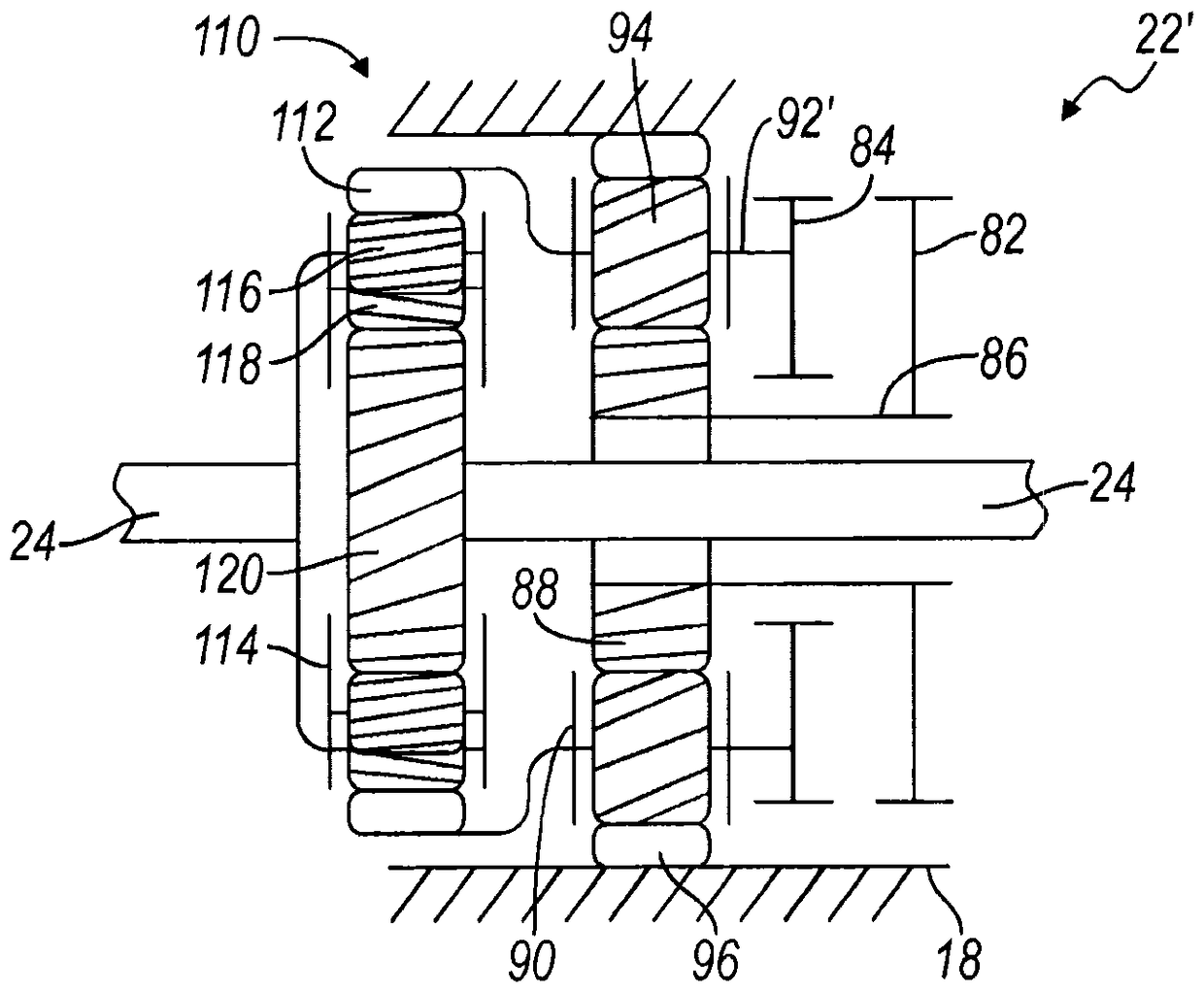

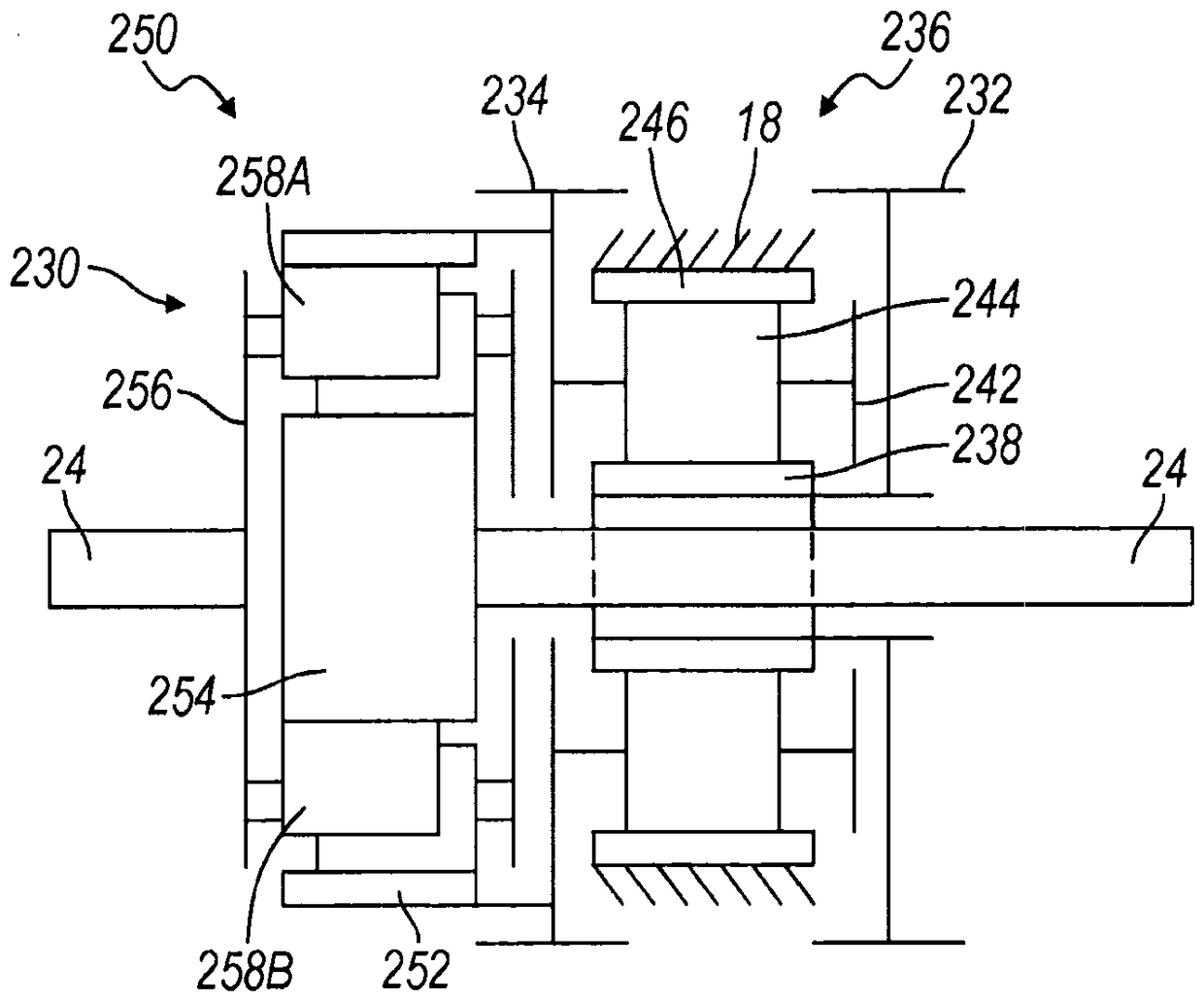

[0045] refer to figure 1 and figure 2 , the front of the motor vehicle is shown schematically and denoted overall by the reference numeral 10 . Motor vehicle 10 includes a body 12 that houses and supports a prime mover 14 , which may be a gasoline, E-85, or diesel internal combustion engine or a hybrid. The output of prime mover 14 is coupled to the input of transaxle 16 , which has a housing 18 that houses and protects a transmission 20 and a final drive assembly 22 , described in detail below. A pair of output or drive shafts 24 extend transversely and coaxially with the transaxle 16 and are coupled to and drive front tire and wheel assemblies 26 through constant velocity joints (not shown). Motor vehicle 10 also includes steering, braking, electrical, fueling and other systems (not shown), which do not form a critical part of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com