Optical connector

A technology for connectors and mating connectors, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of increasing light loss, and achieve the effects of improving anti-fouling, loose mechanical precision requirements, and low light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

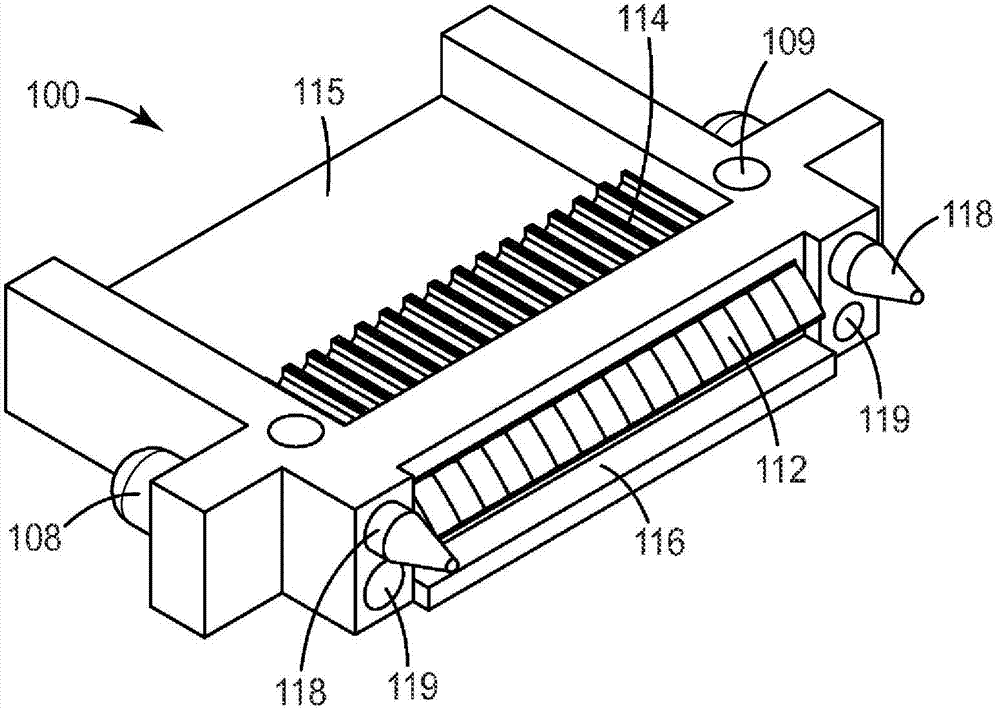

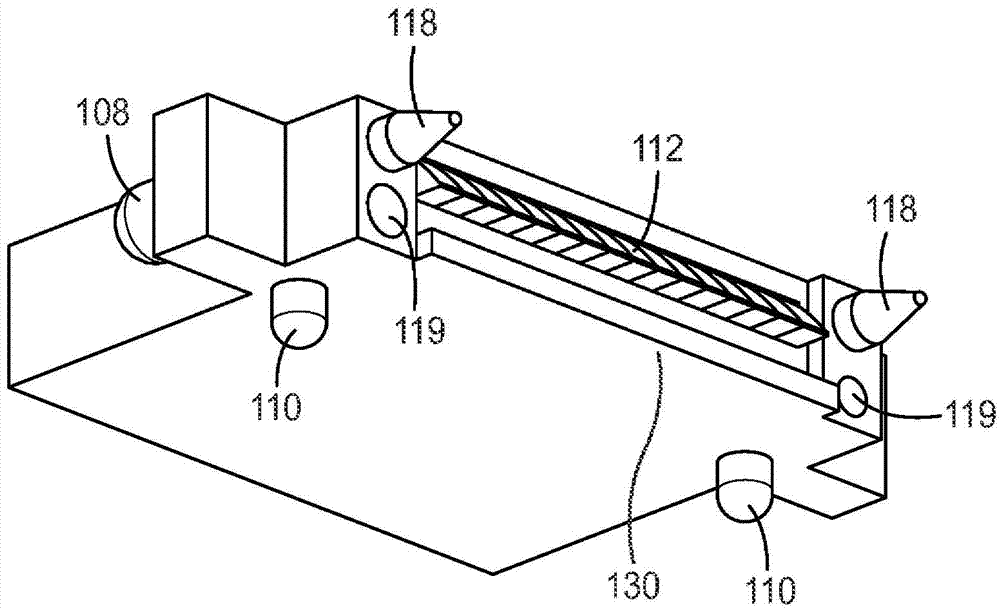

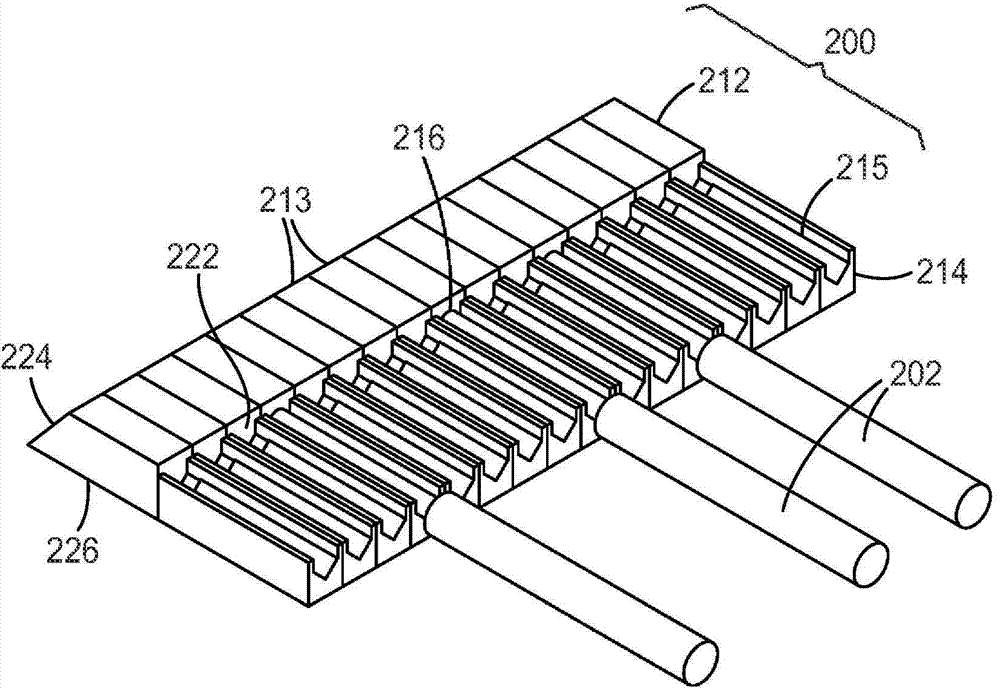

[0023] Fiber optic ribbons are used in fiber optic cables used in many applications. These ribbons consist of a set of coated optical fibers bonded together into a line (typically 4, 8 or 12 fibers in a line). Individual glass optical fibers together with their protective coatings are typically 250 microns in diameter, while fiber-optic ribbons typically have a fiber-to-fiber pitch of 250 microns. This 250-micron pitch has also been used in optical transceivers with a variety of designs, with the active optics spaced by the same 250-micron pitch.

[0024] Currently available expanded beam multi-fiber connectors typically limit the beam diameter to 250 microns to match the ribbon spacing. To achieve beam diameters larger than the fiber pitch, current connectors typically require the fiber ribbon to be separated into individual fibers by hand before the fiber is mounted on the connector.

[0025] Generally, a single fiber optic connector includes a precision cylindrical ferrul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com