Thawing method and device for prolonging freshness of thawed tunas

A tuna freshness technology, applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of unbalanced thawing, long thawing time, adverse consequences, etc., to achieve shortened thawing time, simple operation, and prolonged freshness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

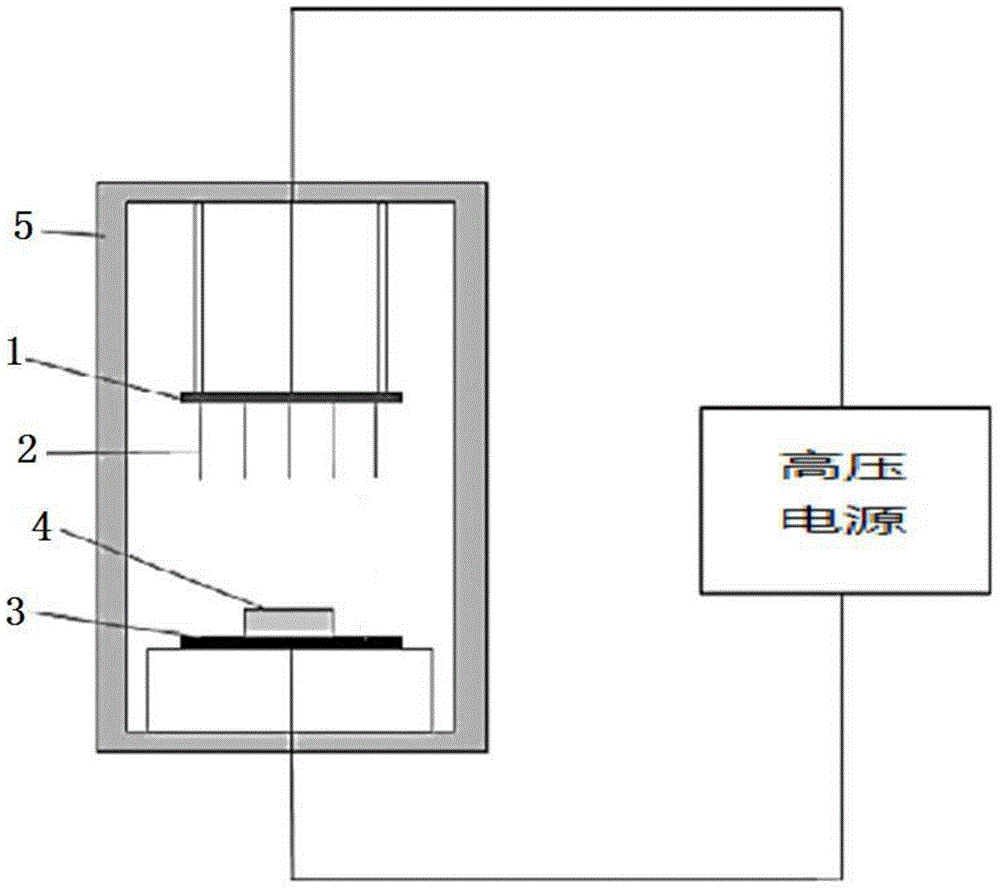

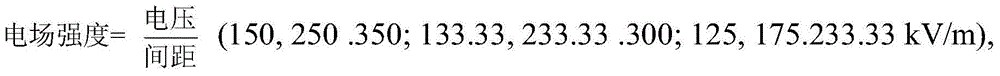

[0025] Such as figure 1 As shown, a thawing device for prolonging the freshness of tuna after thawing, 12 electrode needles 2 are connected to the upper electrode plate 1, and the 12 electrode needles are evenly distributed on the electrode plate in a staggered manner, and point vertically downward to the lower electrode Plate 3, the material of the upper electrode plate 1 is copper, the material of the electrode needle is a circular electrode needle made of stainless steel, the pinhole is downward, and the material of the lower electrode plate is copper. The area of the upper and lower electrode plates is 20×15 cm, and the distance between two adjacent electrode needles is 3 cm. The upper and lower electrode plates and the electrode needles are blocked by the casing 5, and the upper and lower electrode plates are respectively connected to the positive and negative poles of the high-voltage power supply. Among them, the upper electrode plate can move up and down to control t...

Embodiment 2

[0028] Such as figure 1 As shown, a thawing device for prolonging the freshness of tuna after thawing, 12 electrode needles 2 are connected to the upper electrode plate 1, and the 12 electrode needles are evenly distributed on the electrode plate in a staggered manner, and point vertically downward to the lower electrode Plate 3, the material of the upper electrode plate 1 is copper, the material of the electrode needle is a circular electrode needle made of stainless steel, the pinhole is downward, and the material of the lower electrode plate is copper. The area of the upper and lower electrode plates is 20×15 cm, and the distance between two adjacent electrode needles is 3 cm. The upper and lower electrode plates and the electrode needles are blocked by the casing 5, and the upper and lower electrode plates are respectively connected to the positive and negative poles of the high-voltage power supply. Among them, the upper electrode plate can move up and down to control t...

Embodiment 3

[0031] Such as figure 1 As shown, a thawing device for prolonging the freshness of tuna after thawing, 12 electrode needles 2 are connected to the upper electrode plate 1, and the 12 electrode needles are evenly distributed on the electrode plate in a staggered manner, and point vertically downward to the lower electrode Plate 3, the material of the upper electrode plate 1 is copper, the material of the electrode needle is a circular electrode needle made of stainless steel, the pinhole is downward, and the material of the lower electrode plate is copper. The area of the upper and lower electrode plates is 20×15 cm, and the distance between two adjacent electrode needles is 3 cm. The upper and lower electrode plates and the electrode needles are blocked by the casing 5, and the upper and lower electrode plates are respectively connected to the positive and negative poles of the high-voltage power supply. Among them, the upper electrode plate can move up and down to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com