Bacteriocin and ultra-high pressure joint antiseptic preservation technology and its application

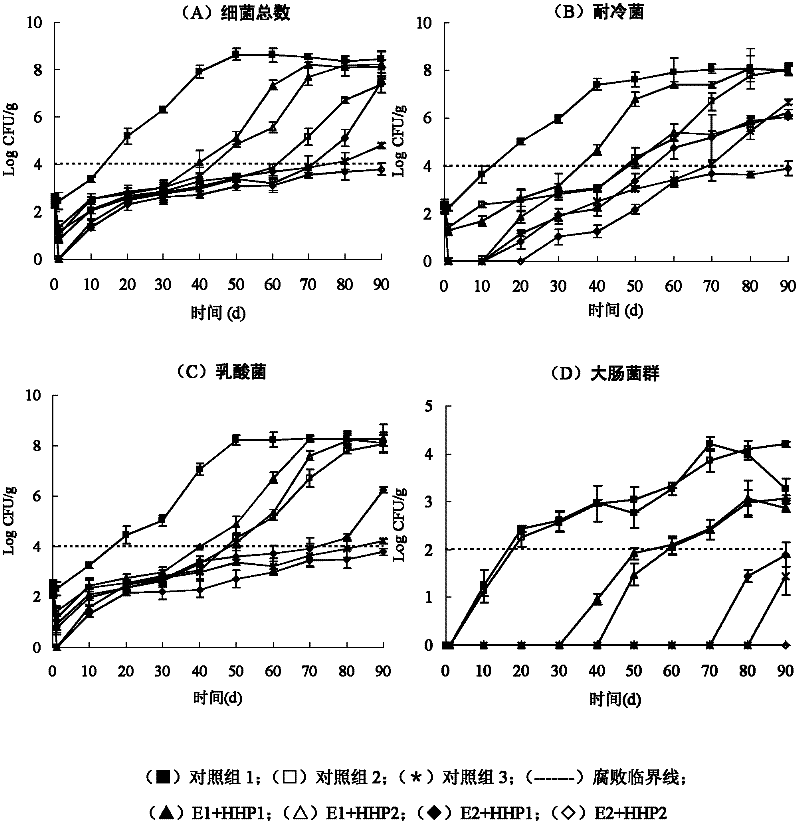

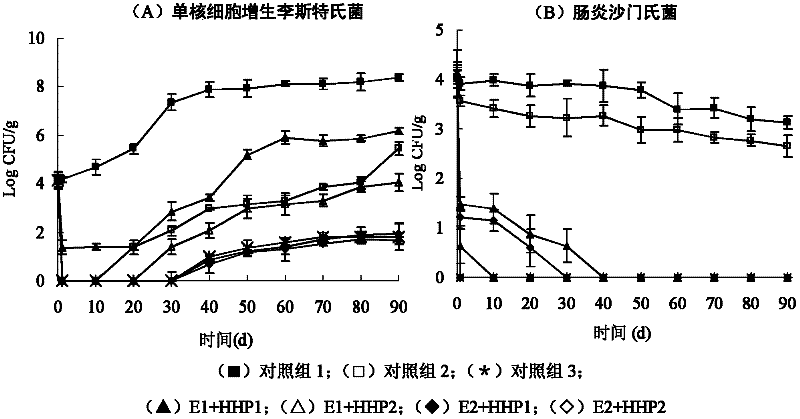

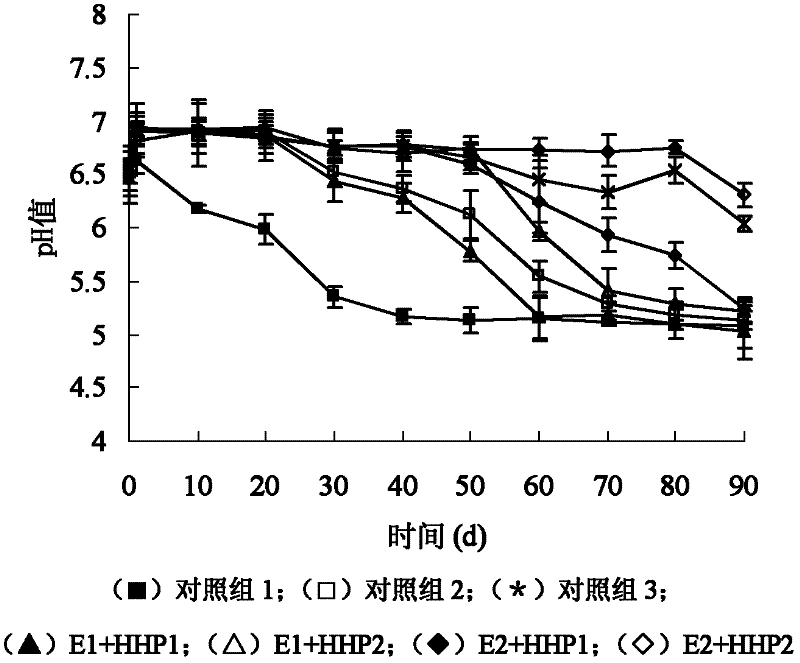

A bacteriocin, ultra-high pressure technology, applied in application, food preservation, food science and other directions, can solve the problems of poor solubility, accelerated product fat oxidation, weak gram-negative bacteria, etc., to maintain color, prolong shelf life, Reduced production and effect of fat oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, the preparation, storage and sampling method of sliced ham treated with bacteriocin and ultra-high pressure

[0026] Method I

[0027] 1. Combined treatment of bacteriocin and ultra-high pressure for antibacterial and / or sterilizing of sliced ham

[0028] The amino acid sequence of the bacteriocin enterocin P is shown in sequence 1 in the sequence listing; the bacteriocin enterocin P is prepared by artificial synthesis.

[0029] 1. Preparation of sliced ham with combined treatment of bacteriocin and ultra-high pressure

[0030] 1) Production and processing of sliced ham

[0031] The production and processing of sliced ham is carried out in the first production workshop of Beijing No. 5 Meat Joint Processing Plant. The production process is carried out according to the formula of the company's commercial product Western-style sliced ham. In addition to the normal addition of nitrite, no preservatives are added .

[0032] 2) Bacteriocin treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com