Staged compacting method and device for crushed fresh alfalfa forage

The technology of alfalfa fresh grass and compacting device is applied in the preservation method of animal feed raw materials, animal feed, application and other directions, which can solve the problems of inability to adapt to the production of small bagged silage of alfalfa, and achieve continuous and stable operation, adjustable density, The effect of reducing the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

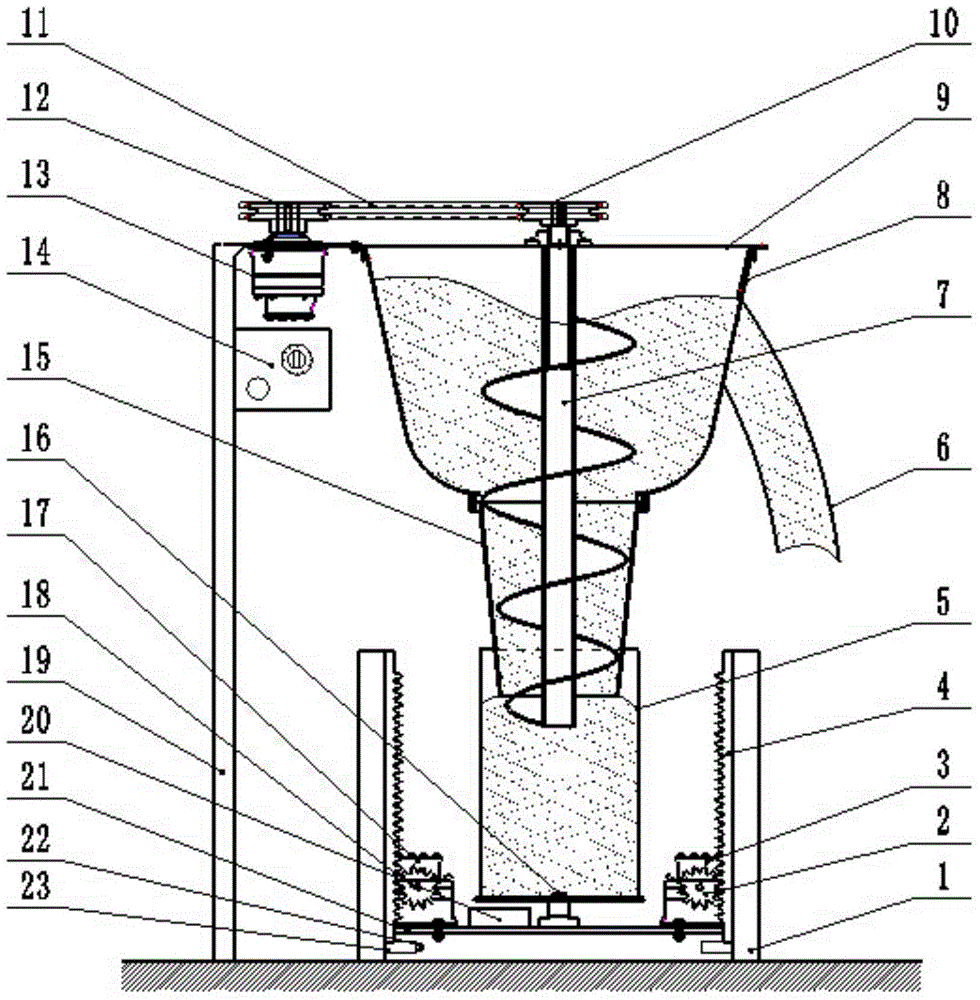

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] The stepwise compaction method of alfalfa fresh grass fragments, the specific steps are as follows:

[0040] 1. Set the compaction parameters: place the compaction barrel at the highest starting position of the lifting device, and set the critical pressure value of the pressure sensor to send the response signal and the working time of one unloading stroke of the unloading hydraulic motor according to the requirements of the alfalfa silage process; According to the preset compaction density, set the gravity compensation value of the compacted material to offset the influence of the gravity of the compacted material on the compaction density;

[0041] 2. Segmented compaction: use the auger to convey and squeeze the fresh alfalfa grass to the compaction barrel;

[0042] 3. Unloading compaction cycle: When the fresh grass and broken materials in the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com