Automatic oil brushing barbecue machine

A skewer machine and automatic technology, which is applied in the direction of roasters/barbecue grids, kitchen utensils, household utensils, etc., can solve the problem of not being able to meet the needs of vegetable multi-moisture skewers, so as to improve the degree of automation and work efficiency. The effect of reducing labor and increasing fun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

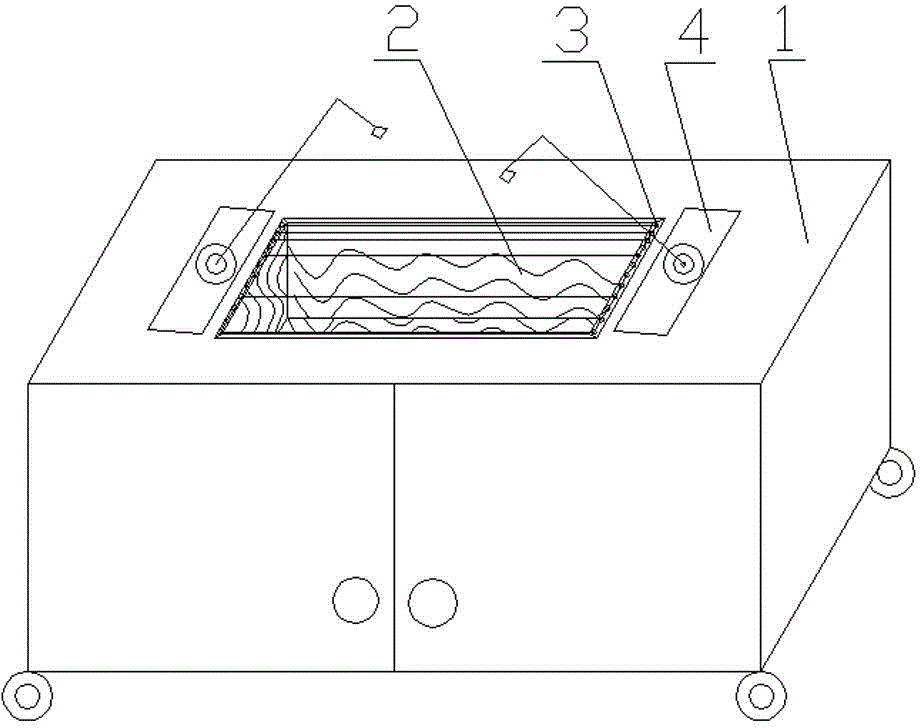

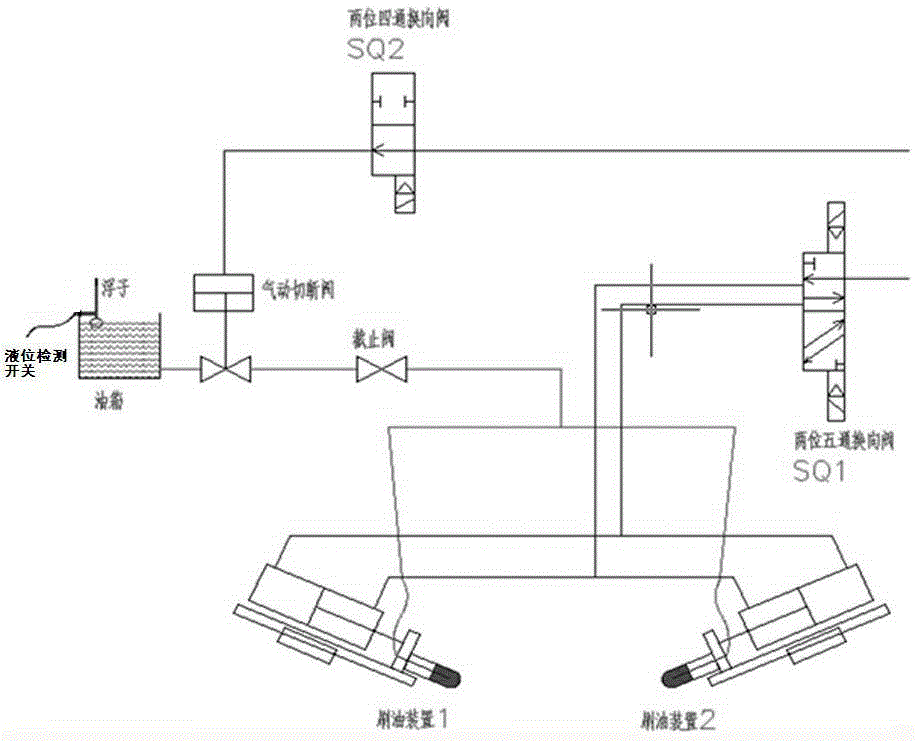

[0018] like figure 1 Shown is an automatic oil-brush skewer machine, an automatic oil-brush skewer machine, comprising a mobile car 1, a heating wire 2, a rotating skewer rack 3 and an oil brushing assembly 4, characterized in that the mobile car 1 is a cuboid that is hollow inside and has a groove on the top; the heating wire 2 is a resistance heating wire, and is arranged on the four walls of the groove of the mobile vehicle 1; In the slot; the brushing assembly 4 includes a frame and an oil tank installed on the frame, an air pump, a brushing device, and a detection control device; the frame is arranged on both sides of the top of the groove; the detection The control device includes the switch circuit of the rear press car and the fuel injection solenoid valve connected thereto, and the telescopic arm solenoid valve; The oil head is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com