Special automatic fire extinguishing device for battery box

An automatic fire extinguishing and battery box technology, applied in fire rescue and other directions, can solve the problems of power battery or capacitor explosion and combustion, unsatisfactory fire extinguishing effect, endangering the lives of people in the vehicle, etc., to improve the utilization rate and respond quickly. , control flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

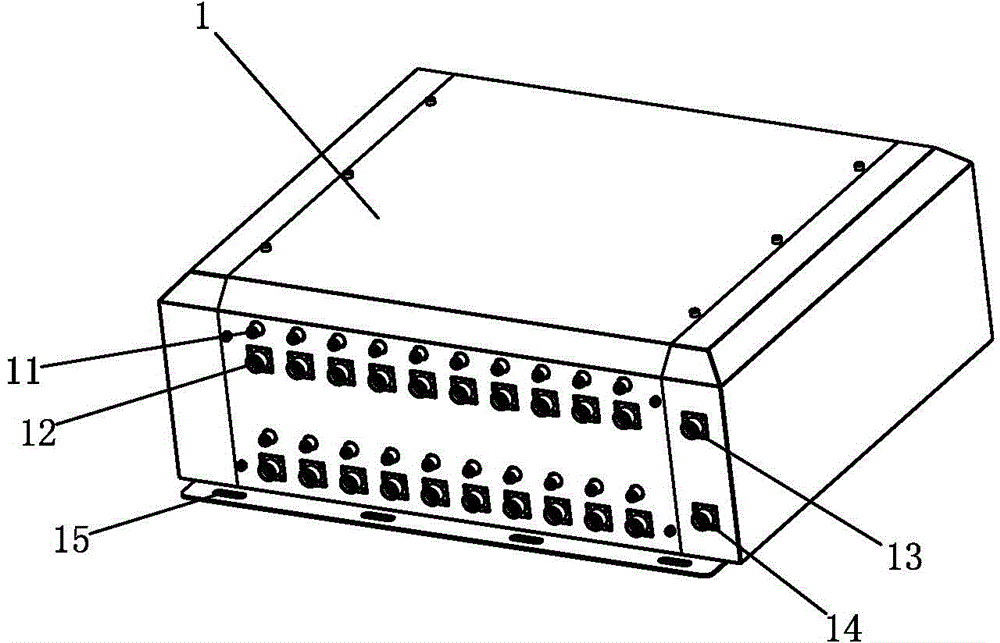

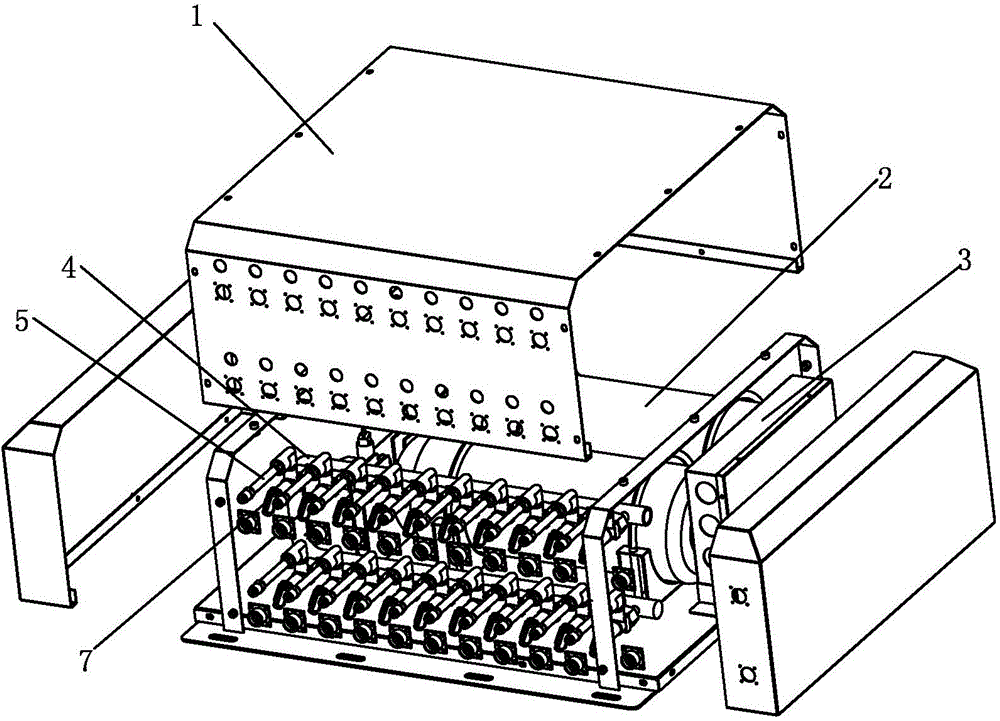

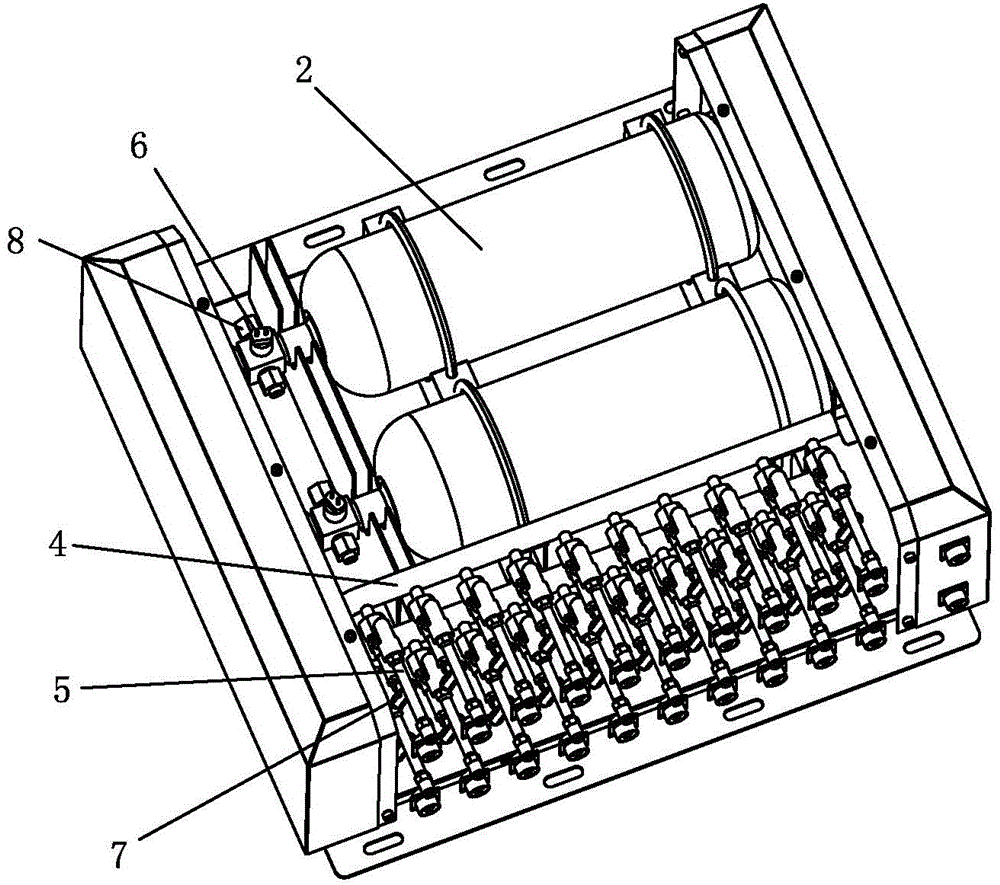

[0029] Examples, see Figure 1-Figure 3 As shown, a special automatic fire extinguishing device for a battery box of the present invention is used to extinguish the fire of the power battery or supercapacitor in the battery box of the vehicle (in this embodiment, take a new energy bus as an example), and it includes:

[0030] A plurality of aspirating fire detectors (not shown in the figure) are used to detect whether there is fire in each battery box. During installation, each battery box of the bus is equipped with at least one of the aspirating fire detectors. Specifically, The aspirating fire detector can collect the gas released when the power battery or super capacitor is at high temperature and the smoke generated when the fire occurs;

[0031] At least two fire extinguishing agent containers 2 are equipped with fire extinguishing agent and are pressure storage type. Specifically, the fire extinguishing agent can be a mixed gas fire extinguishing agent and / or an ultrafi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com