Dry-type separation and recovery system and process for circuit boards

A separation and recycling, circuit board technology, used in electronic waste recycling, recycling technology, solid waste removal and other directions, can solve the problems of water pollution, secondary environmental pollution, etc., to prevent dust pollution, improve quality, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

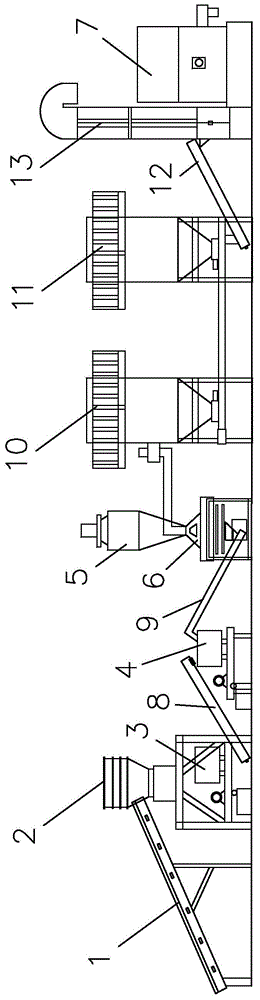

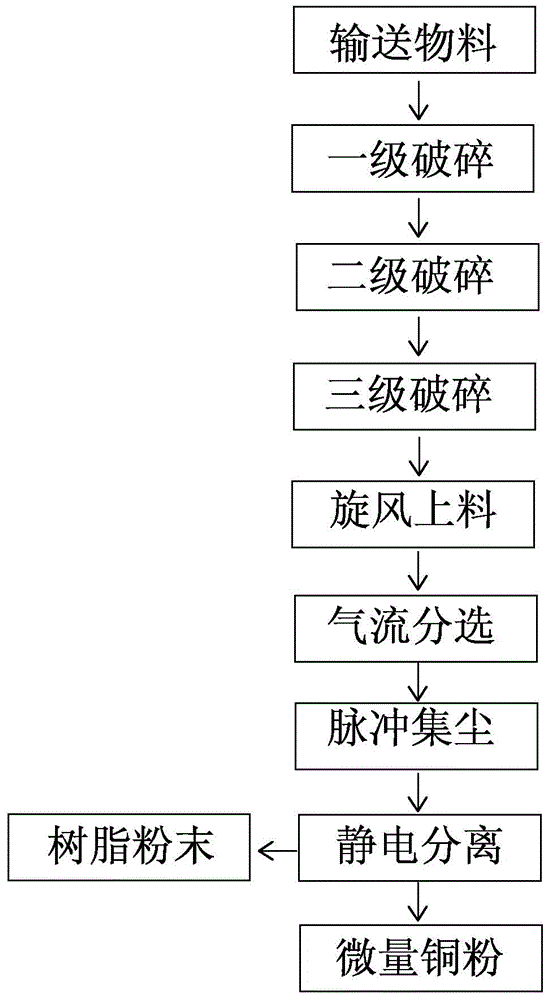

[0024] Such as figure 1 As shown, a circuit board dry separation and recovery system includes a crushing production line and a separation production line. The primary pulverizer 2 is arranged below the discharge port of the primary pulverizer 1; the separation production line includes a cyclone feeder 5, an airflow separator 6, dust removal equipment and an electrostatic separator 7 in sequence, and the airflow separator 6 is arranged in the cyclone Below the feeding machine 5.

[0025] An auger machine 8 for transporting materials is provided between the third-stage pulverizer 4 and the secondary pulverizer 3 . A second conveyor 9 is provided between the tertiary pulverizer 4 and the cyclone feeder 5 . The dust removal equipment includes a first pulse dust collector 10 and a second pulse dust collector 11 .

[0026] The number of the aforementioned crushing production lines is one, while the number of separation production lines is two, which are arranged side by side. Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com