Numerical control boring machine for machining thrust surface of engine cylinder body

An engine cylinder block and thrust surface technology, applied in the field of CNC boring machines, can solve the problems affecting the overall performance of the engine, poor machining accuracy and roughness compensability of the two thrust surfaces, etc., to achieve good operability, improve product quality and The effect of working efficiency and shortening auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

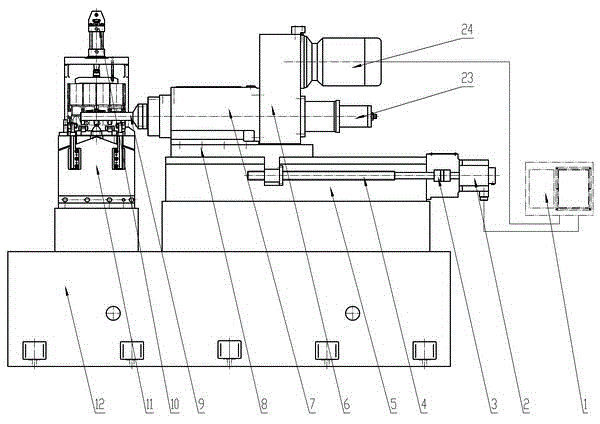

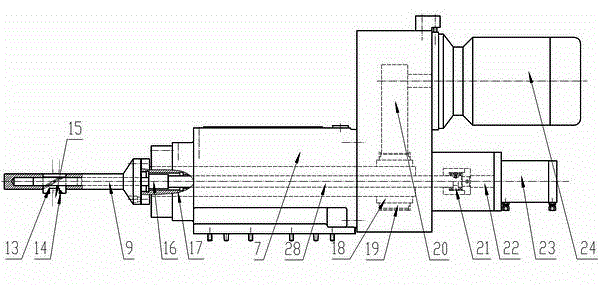

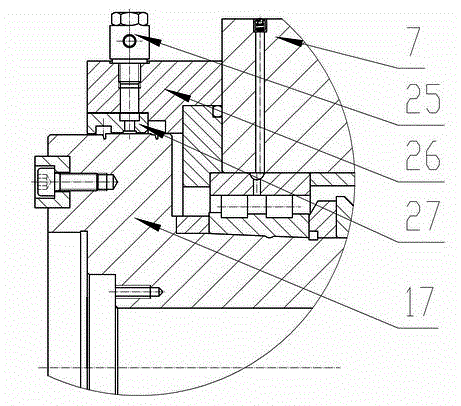

[0010] like figure 1 , figure 2 , image 3 As shown, the electrical system 1 of the present invention is connected with the servo motor 2 and the motor 24; The ball screw pair 4 in the slide seat 5 is connected through the coupling 3, the ball screw pair 4 is connected with the slide plate 8 through threads, the slide plate 8 is slidingly matched with the guide rail on the slide seat 5, and the slide plate 8 is in the position of the servo motor 2. Driven to realize lateral movement; the boring head 7 is fixed on the slide plate 8, the belt pulley 19 of the transmission device 6 is connected with the motor 24 on the transmission device 6 through the belt 20, and the belt pulley 19 is connected with the motor of the boring head 7 through the spline sleeve 18 The main shaft 17 is connected, the boring bar 9 is connected with the main shaft 17, the motor 24 drives the boring bar 9 to rotate through the main shaft 17; the push rod cylinder 23 is fixed on the transmission device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com