Efficient numerical control machining method for integral titanium alloy impeller and matched tool clamp

A technology of integral impeller and processing method, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high processing difficulty, difficult processing of titanium alloy materials, poor tool rigidity, etc., and achieve convenient and simple loading and unloading of workpieces, Good safety performance and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

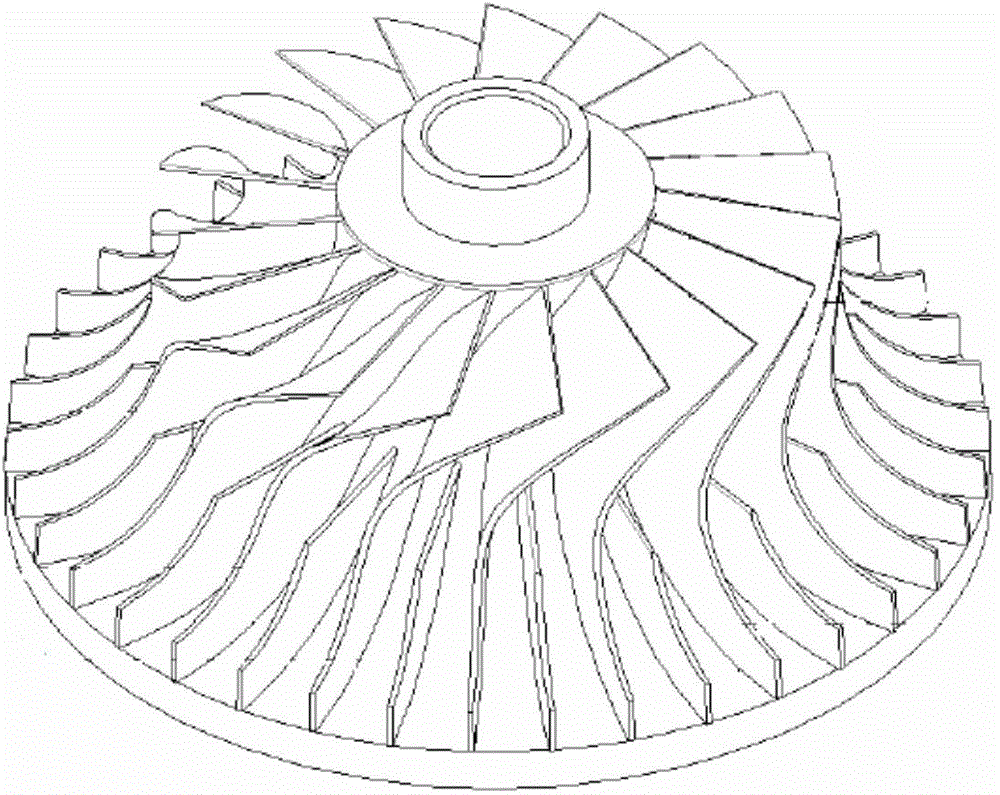

[0043] 1. Processing such as figure 1 The shown diameter is 360mm, the length of the blade is 86mm, and the narrowest part of the hub is 12mm. The overall impeller with a blade thickness of 2mm.

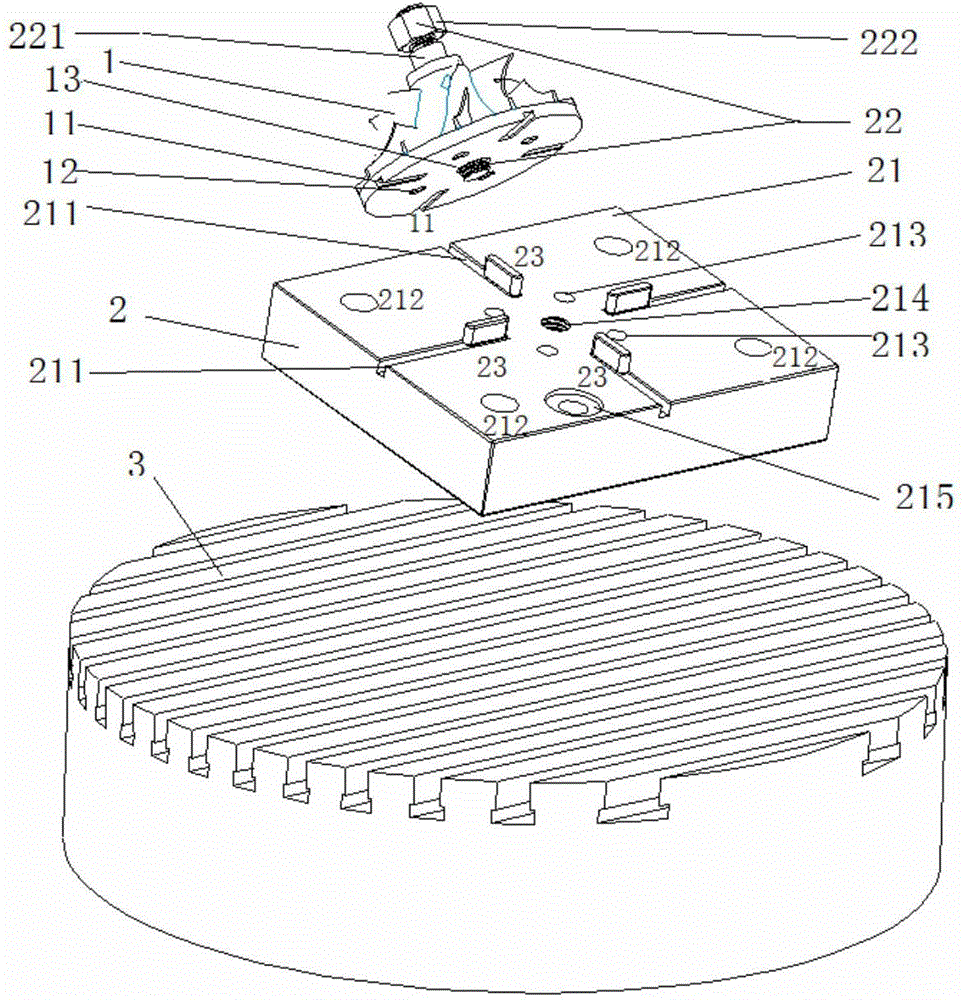

[0044] Such as image 3 The shown special fixture includes a fixture bottom plate 21, a fixing mechanism 22 that is perpendicular to the fixture bottom plate 21 and fixedly connected with the fixture bottom plate 21, and also includes an impeller blank 1 and a positioning key 23 that play a connecting role. The fixture bottom plate 21 There is a first guide groove 211 opening from the side to the middle, the positioning key 23 is installed in the first guide groove 211, and the impeller blank 1 is correspondingly provided with a second guide groove 11 with the same width. When cooperating with the positioning key 23, the first counterbore 212 for f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com