Biological fluidized bed reactor

A biological fluidized bed and reactor technology, applied in waste fuel, anaerobic digestion, etc., can solve the problems of high suspended matter content, difficult solid-liquid separation, high processing cost, etc., to facilitate circulation, promote genetic evolution, enhance The effect of processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

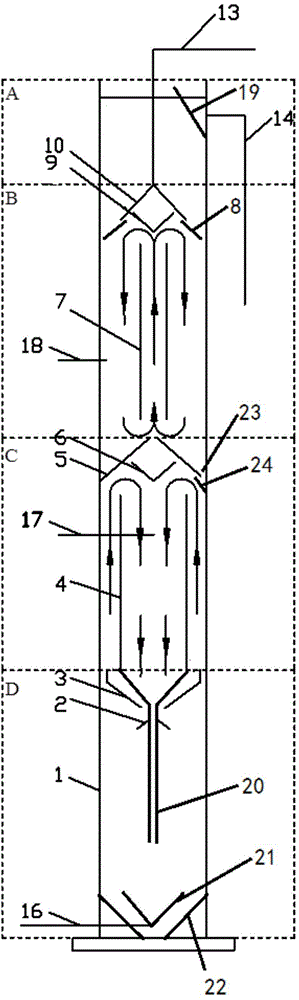

[0026] Biological fluidized bed reactor structure of the present invention such as figure 1 shown. Among them, the solid-liquid separation zone A, the second internal circulation zone B, the first internal circulation zone C, and the complete mixing zone D. The reactor in the present invention is provided with a biofilm carrier with a biofilm formed by microorganisms attached to the surface, and sand is used in this embodiment. When the sewage flows from the water inlet pipe 16 to the water inlet branch pipe 21, the sewage flowing out of the water inlet branch pipe 21 mixes with the biofilm carrier with microorganisms to generate biogas. Under the buoyancy of biogas, the driven material flow rises in the complete mixing zone, and when it reaches the first air guide plate 2, the material flow is guided by the conical outer surface of the first air guide plate 2 to the first inner circulation area, along the first air guide plate 2. The outer wall of an inner circulation sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com