Silicon carbide waste-doped dry-powder front mortar and preparation method thereof

A technology for silicon carbide waste and plastering mortar, which is applied in the field of building materials, can solve problems such as affecting the service performance of mortar, mortar spalling, mortar stress concentration, etc., and achieves the effect of being beneficial to commercial promotion, reducing dosage and improving later strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

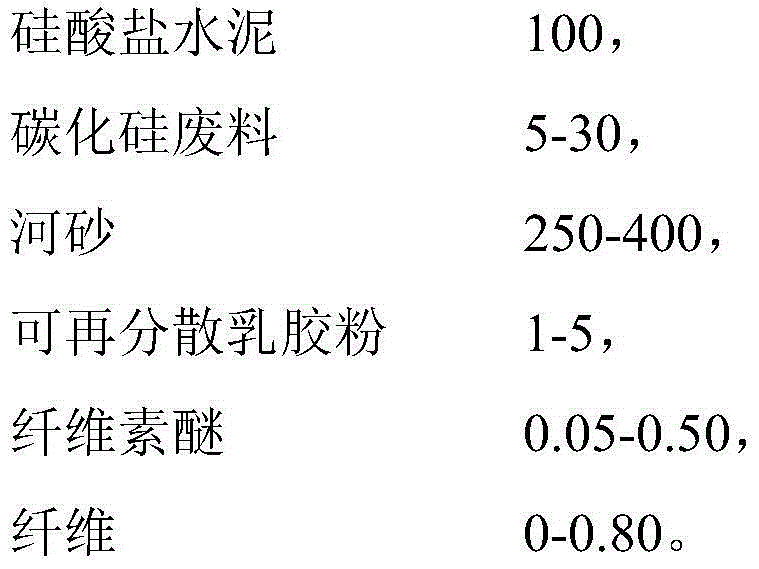

Method used

Image

Examples

Embodiment 1

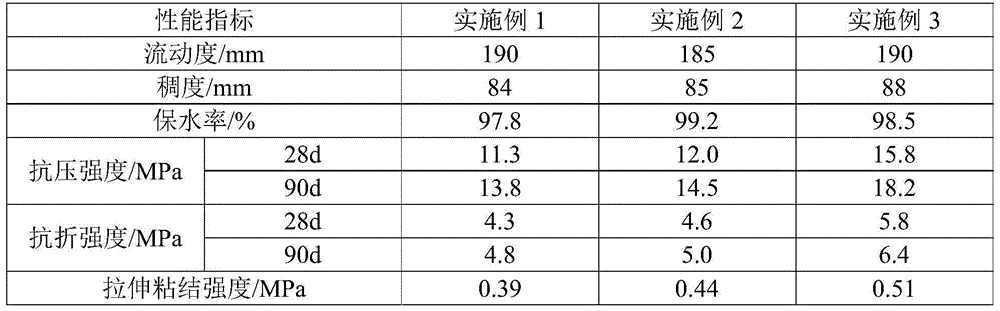

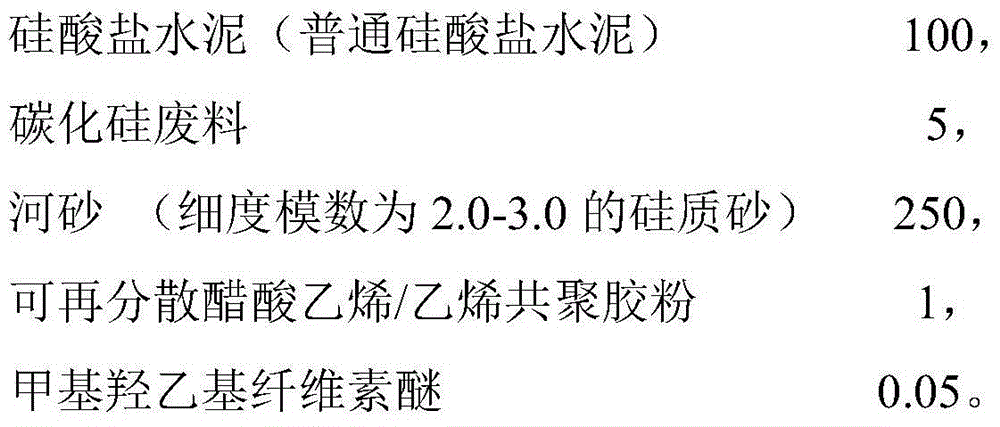

[0034] A dry powder plastering mortar mixed with silicon carbide waste, according to the weight of 42.5 grade ordinary Portland cement 100, silicon carbide waste 10, river sand 330, redispersible latex powder 2, cellulose ether 0.1, fiber 0.45, water 69 than formulated. The performance test results are shown in Table 1.

Embodiment 2

[0036] A dry powder plastering mortar mixed with silicon carbide waste, according to the weight of 42.5 grade ordinary Portland cement 100, silicon carbide waste 20, river sand 330, redispersible latex powder 2, cellulose ether 0.1, fiber 0.45, water 69 than formulated. The performance test results are shown in Table 1.

Embodiment 3

[0038] A dry powder plastering mortar mixed with silicon carbide waste, according to the weight of 52.5 grade ordinary portland cement 100, silicon carbide waste 20, river sand 330, redispersible latex powder 2.5, cellulose ether 0.08, fiber 0.5, water 75 than formulated. The performance test results are shown in Table 1.

[0039] Table 1 embodiment 1-embodiment 3 performance test results

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com