Technology method for obtaining high-strength silk fibers and preparation device for high-strength silk fibers

A technology of silk fiber and process method, applied in the textile field, can solve the problems of complex process and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

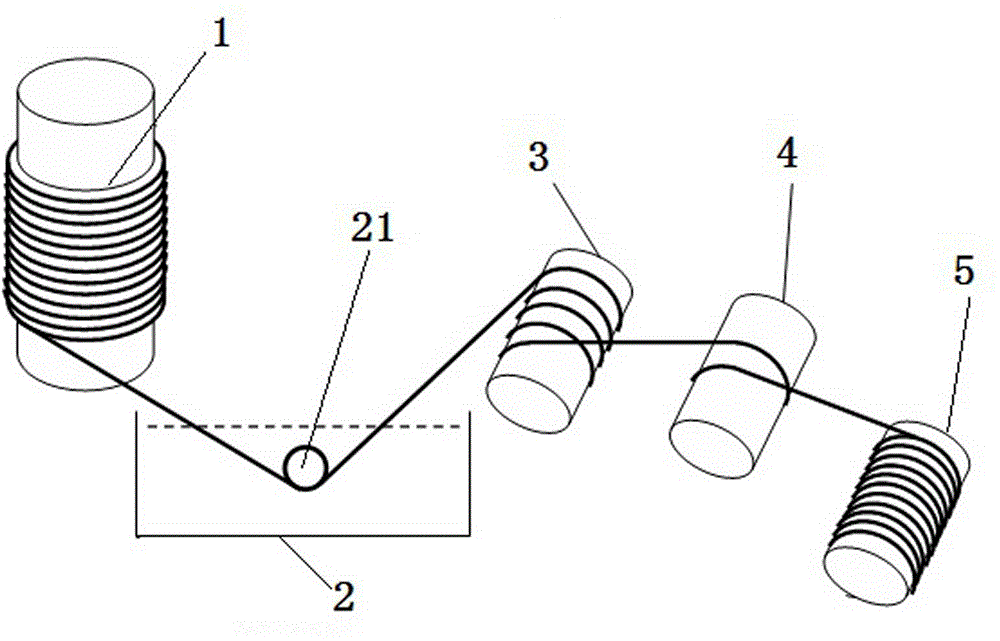

preparation example Construction

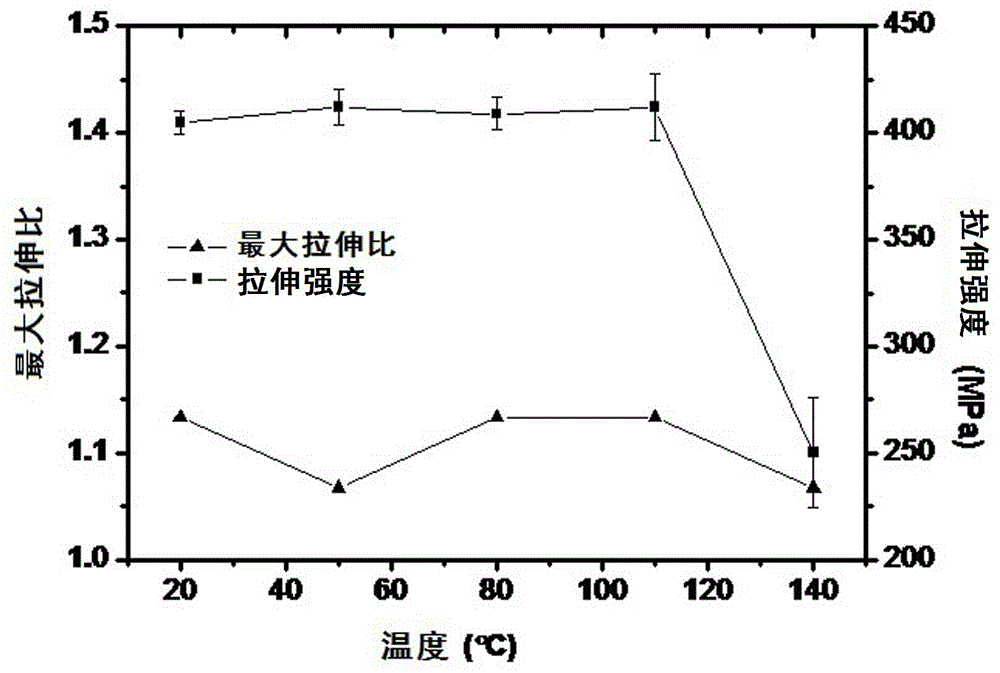

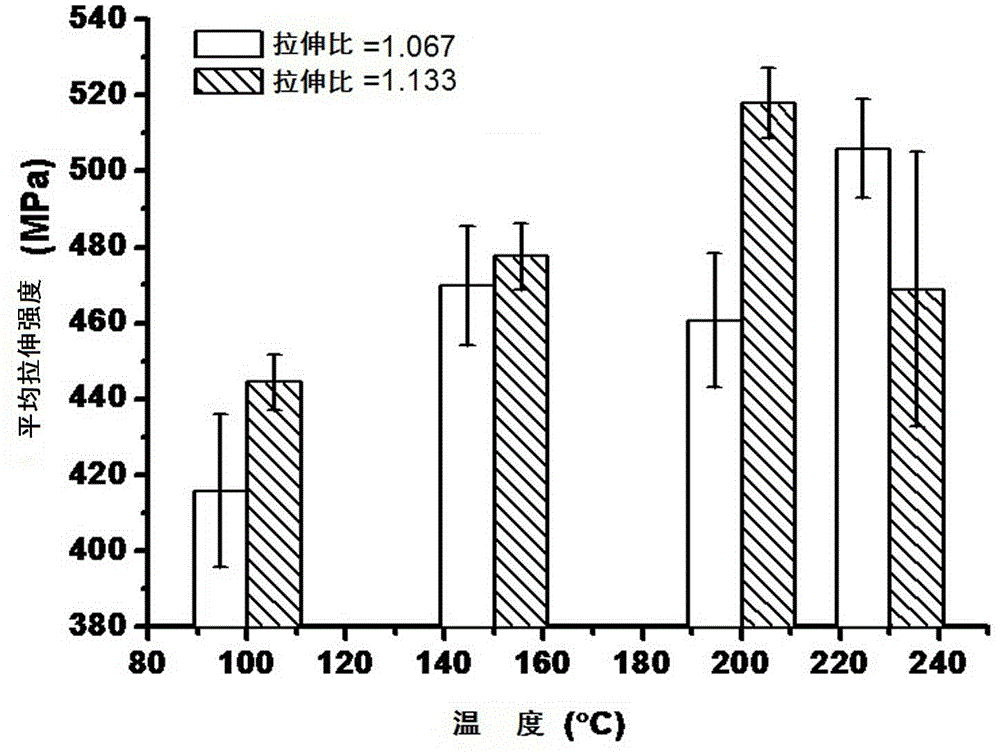

[0034] The preparation process steps of the present invention are as follows: 1) Coating treatment: the silk thread obtained by pulling and twisting is passed through a polyethylene glycol bath for coating treatment, after coating treatment, it is wound on the feeding roller, the temperature of the polyethylene glycol bath controlled at room temperature to 80 0 Between C; 2) Stretching heat setting treatment: the silk thread wound on the feeding roller is stretched and wound on the heating roller for heat setting treatment; the stretching ratio is controlled by controlling the linear speed of the feeding roller and the heating roller, The stretch ratio is controlled between 1.05 and 1.3; the temperature of the feeding roller is controlled at room temperature to 110 0 C; the temperature of the heating roller is controlled at 150 0 C ~230 0 C; the silk thread is wound on the heating roller for 0.5 to 5 seconds; 3) cooling and collection, the silk thread after being heat-set by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com