Porous structure bone cement screw design and manufacturing method thereof

A porous structure and structural design technology, applied in the field of medical devices, can solve problems such as rust, bone secondary injury, implant shedding, etc., to achieve the effect of expanding the application range, promoting rapid recovery, and avoiding secondary injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The bone cement screw with porous structure of the present invention will be further described below in combination with specific examples.

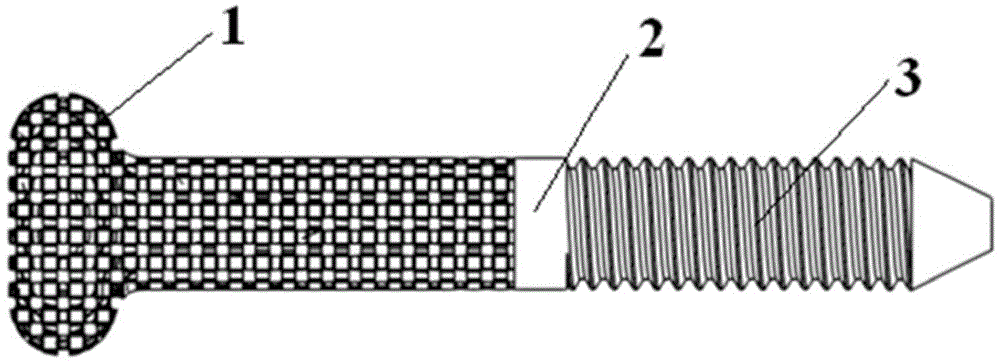

[0026] Such as figure 1 As shown, a bone cement screw with a porous structure of the present invention includes a porous support body 1 , a solid cylinder body 2 and a threaded body 3 connected in sequence. In order to make the porous support body 1 and the threaded body 3 tightly combined, the middle solid cylinder 2 plays a transitional role, and the ratio of its length to diameter should be at least 1:1. And the length of the thread body is 30%-80% of the whole porous structure bone cement screw; the porosity of the porous support body 1 is 30%-80%. The surface of the solid cylinder is smooth, and in order to ensure the bonding strength with the porous support and the threaded part, its length should be at least 2 mm.

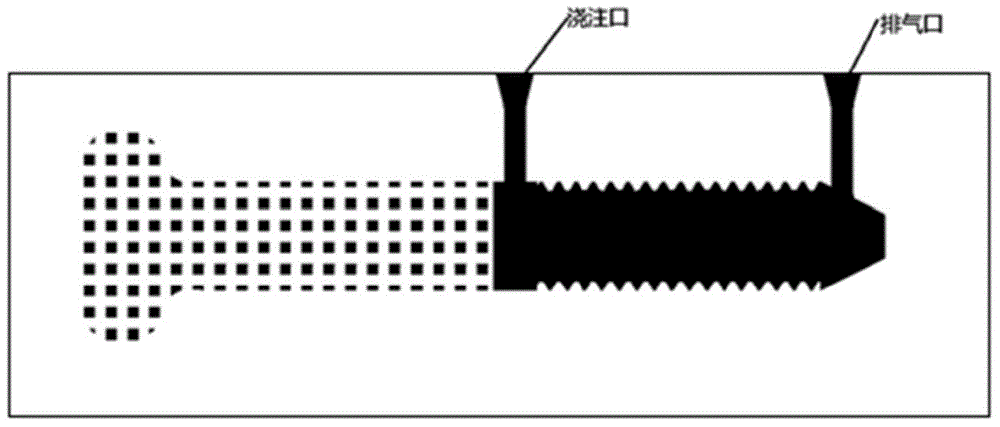

[0027] see figure 2 Shown, the preparation method of a kind of porous structure bone cement screw of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com