Online monitoring and diagnosis device and method for intelligent pre-filter

A pre-filter and intelligent diagnosis technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problem of contamination of filter elements, affecting the safe and stable operation of the thermal system, and the inability to indicate the operating status of the pre-filter in real time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0110] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

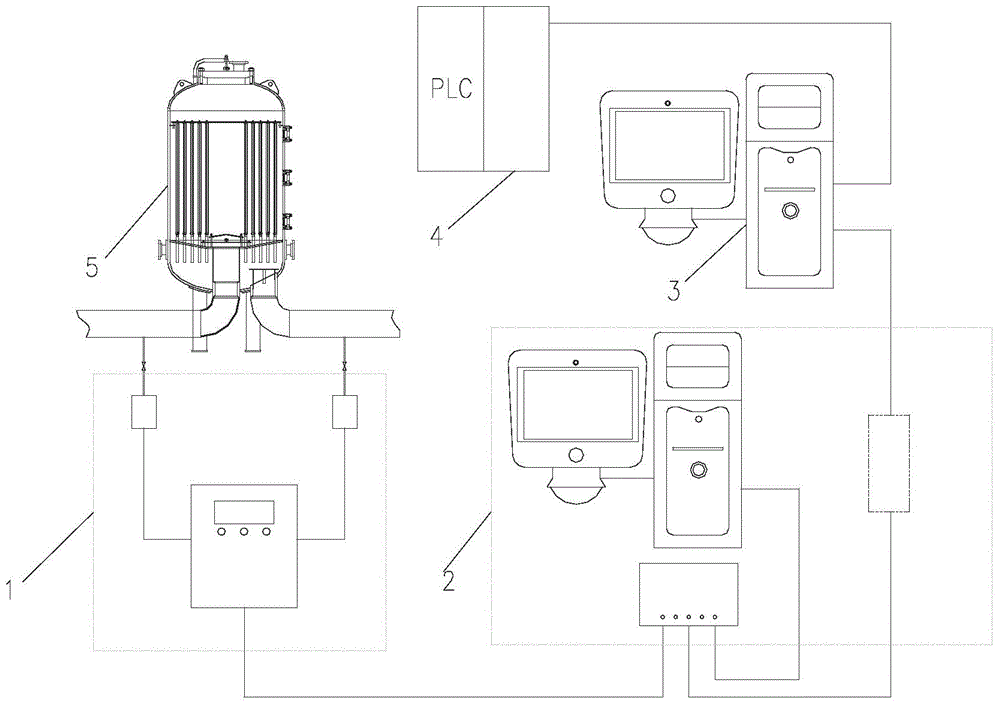

[0111] Such as figure 1 As shown, an intelligent pre-filter online monitoring and diagnosis device of the present invention includes a pre-filter 5 connected in sequence, an intelligent sampling distribution system 1, an intelligent diagnostic unit 2, and a pre-filter operating program-controlled PLC host computer 3 And pre-filter operation program-controlled PLC4, the intelligent sampling distribution system 1 monitors the number, volume and particle size distribution indicators of suspended particles in multiple water samples, and transmits the data to the intelligent diagnostic unit 2 for storage and analysis through the MODBUS communication protocol .

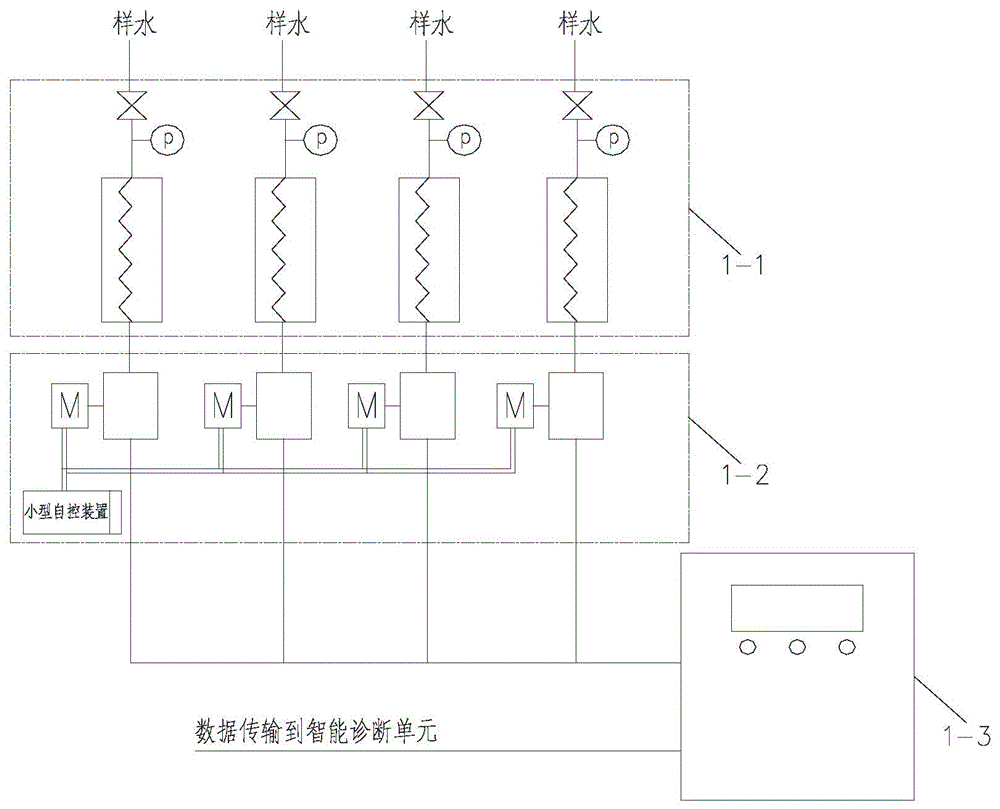

[0112] Such as figure 2 As shown, the intelligent sampling distribution system 1 includes a sampling cooling device 1-1 connected to the water inlet and outlet of the pre-filter...

Embodiment 1

[0115] The technical scheme is illustrated by evaluating the present invention in the operation of a powder resin covered filter in a certain supercritical air-cooled unit power plant in northern my country.

[0116] The two 600MW supercritical units of the power plant are direct air-cooled units, and the pre-filter of the condensate polishing system uses powder resin to cover the filter. Table 4 shows the particle size distribution and suspended particle removal rate of the condensate inlet and outlet water measured by the online laser particle counter, and the average suspension content calculated according to the volume concentration of the inlet and outlet particles.

[0117] Table 4 Suspended matter removal efficiency data table of powder filter

[0118]

[0119]

[0120] From the data in Table 4, it can be seen that the removal rate of suspended iron particles in the powder resin-covered filter of this power plant is low, and there are still suspended iron particle...

Embodiment 2

[0124] A wet-cooled power plant near the sea in northern my country is selected. The pre-filter used in this power plant is a tubular filter, and a pleated filter element with a filtration accuracy of 5 μm is selected. According to the sampling and calculation of the intelligent pre-filter on-line monitoring and diagnosis device, the particle size distribution of the suspended solids in the water entering and leaving the pre-filter and the removal rate of the suspended solids by the tubular filter are shown in the following table:

[0125] Table 5 Suspended solids removal efficiency data table of tubular filter

[0126]

[0127] The filter element of the tubular filter in this power plant has a filtration precision of 5 μm, which cannot effectively intercept suspended particles below 5 μm, and the removal rate of suspended particles is only 50%. However, the feed water of this power plant is treated with oxygen addition, and the iron content in the condensed water is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com