Method for improving yield of arachidonic acid through fermentation production of mortierella alpina

A technology of Mortierella alpina and arachidonic acid, applied in the field of microbial fermentation, can solve the problems of low content, not widely used, unsuitable for industrial production, etc., and achieve the effect of low cost and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of oleic acid: oleic acid is sterilized through a syringe filter, using an organic filter head of 0.22 μm.

[0033] 2) Shake flask seed culture: Under sterile conditions, take an appropriate amount of Mortierella alpina spores or mycelium and spread it on PDA medium, and culture it at 25-30°C for 7 days (5-8 days are determined according to the actual growth status. determined, each time is not necessarily the same), and then scrape an appropriate amount of spores into the Erlenmeyer flask containing the shaker flask seed medium, culture on a shaking table at 27°C and a humidity of 45% for 30 hours, and the shaking table speed is 200rpm to obtain seeds; the seeds The medium is glucose 50g / L, yeast powder 20g / L, pH 6.8; the formula of PDA medium is: glucose 20g / L, potato 150g / L, agar powder 15g / L, K 2 PO 4 0.4g / L,MgSO 4 0.2g / L, pH 6.5-7.0.

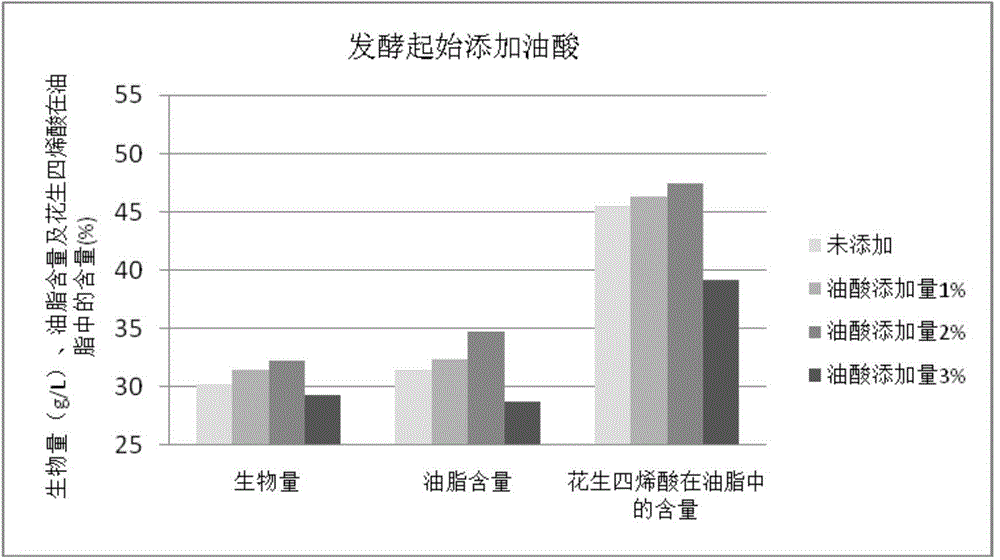

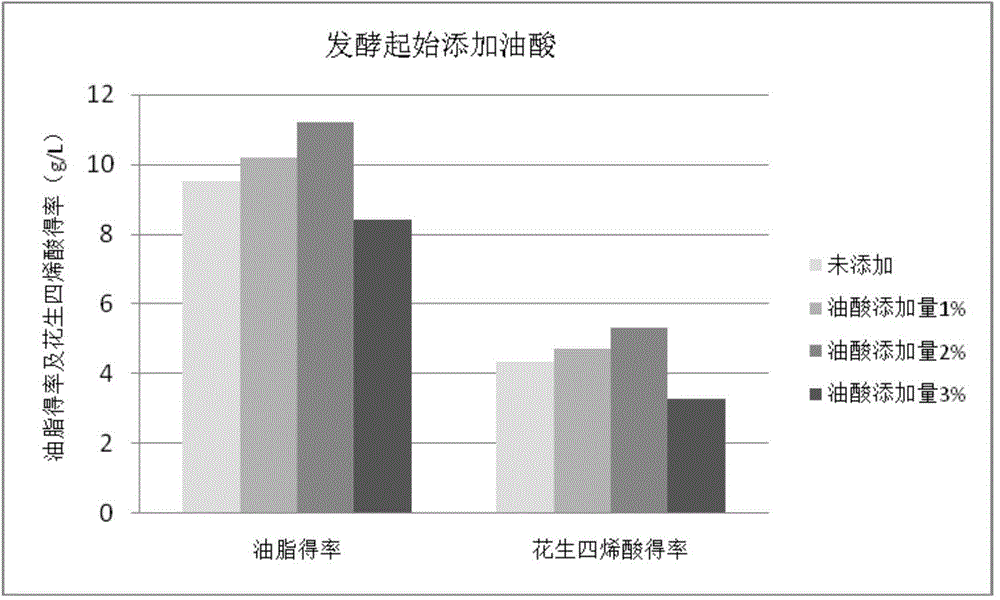

[0034] 3) Shake flask fermentation culture: put the seed liquid into the Erlenmeyer flask containing the fermen...

Embodiment 2

[0047] 1) The preparation of oleic acid is the same as in Example 1.

[0048] 2) The shake flask seed cultivation method is the same as in Example 1.

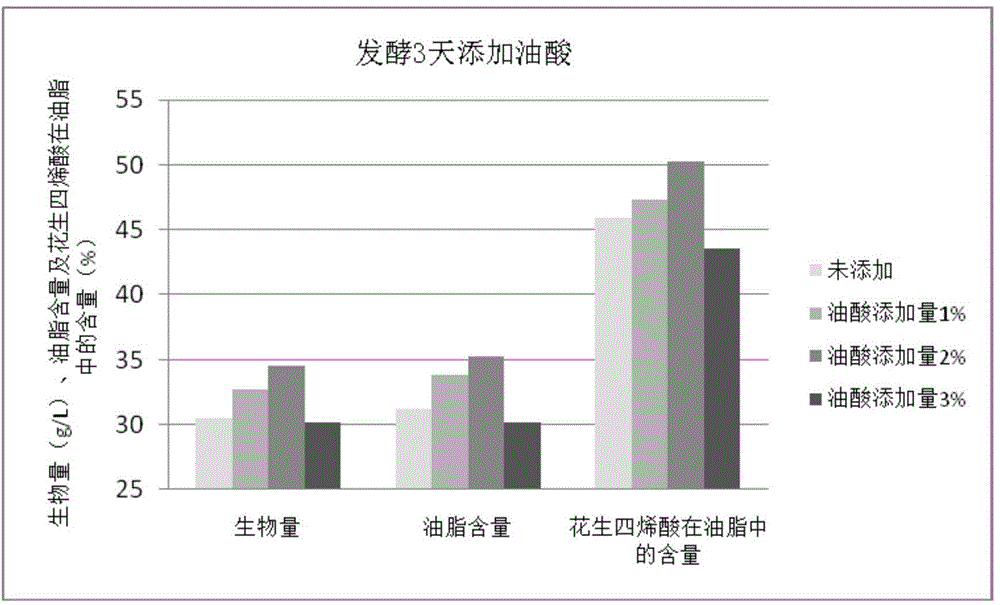

[0049] 3) Shake-flask fermentation culture: For shake-flask fermentation culture, transfer the seed liquid into a triangular flask containing fermentation medium according to the inoculum amount of 10%, and cultivate it on a shaker for 8-14 hours at 25-30°C and humidity 30%-60%. day, the rotating speed of the shaking table is 180-250rpm; when fermenting for 3 days, 1%, 2%, 3% oleic acid and the fermented liquid are respectively emulsified by the surfactant lecithin, wherein the lecithin addition is 1%, and the conversion After the emulsification, continue to culture on a shaker.

[0050] There is also a control group without adding oleic acid and only adding an equal amount of lecithin, pH 7.0-7.5, and there are 3 parallel fermentation bottles for each group of experiments, and unseparated arachidonic acid oil is obtained afte...

Embodiment 3

[0055] 1) The preparation of oleic acid is the same as in Example 1.

[0056] 2) The shake flask seed culture method is the same as in Example 1.

[0057] 3) Shake flask fermentation culture: For shake flask fermentation culture, put the seed liquid into the triangular flask containing the fermentation medium according to the inoculation amount of 10%, and cultivate it on the shaker at 25-30°C and humidity 30%-60% for 8-14 day, the rotating speed of the shaker is 180-250rmp; when fermenting for 6 days, 1%, 2%, and 3% oleic acid and the fermentation broth are respectively emulsified by the surfactant lecithin, wherein the lecithin addition is 1%, and the conversion After the emulsified liquid was cultured on a shaker, there was also a control group without adding oleic acid and only adding the same amount of lecithin, pH 6.5-7.0, and each group of experiments had 3 parallel fermentation bottles, and arachidonic acid oil was obtained after the fermentation ; The fermentation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com