Novel container fireproof floor and manufacturing method of novel container fireproof floor

A container and floor technology, which is applied to the new type of container fireproof floor and its manufacturing field, can solve the problems of lack of sterilization and cleaning, easy breeding of various bacteria, and impact on personnel health, and achieve excellent flame retardancy, low cost, and manufacturing methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

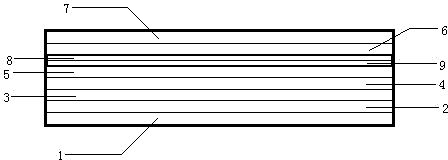

[0032] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention provides a novel container fireproof floor, which includes an aluminum foil layer 1, a lower non-woven fabric layer 2, a lower mesh cloth layer 3, a middle material layer 4, and an upper mesh cloth layer from bottom to top Layer 5, mixing layer, batter layer 6 and PVC layer 7, wherein the thickness of PVC layer 7 is 1-2mm

[0033] Its manufacturing method is:

[0034] (1) Prepare a plate-shaped mold, and lay soft foil of the same size in it as the aluminum foil layer 1;

[0035] (2) Prepare a non-woven fabric with a grammage of 14 grams as the lower non-woven fabric layer 2, and evenly coat the adhesive on the surface of the aluminum foil layer 1, and lay the lower non-woven fabric layer 2 on the surface of the aluminum foil layer 1;

[0036] (3) On the upper surface of the lower non-woven fabric layer 2, two layers of interwoven mesh cloth with a specification of ...

Embodiment 2

[0044] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention provides a novel container fireproof floor, which includes an aluminum foil layer 1, a lower non-woven fabric layer 2, a lower mesh cloth layer 3, a middle material layer 4, and an upper mesh cloth layer from bottom to top Layer 5, mixing layer, batter layer 6 and PVC layer 7, wherein the thickness of PVC layer 7 is 1-2mm

[0045] Its manufacturing method is:

[0046] (1) Prepare a plate-shaped mold, and lay soft foil of the same size in it as the aluminum foil layer 1;

[0047] (2) Prepare a non-woven fabric with a grammage of 14 grams as the lower non-woven fabric layer 2, and evenly coat the adhesive on the surface of the aluminum foil layer 1, and lay the lower non-woven fabric layer 2 on the surface of the aluminum foil layer 1;

[0048] (3) On the upper surface of the lower non-woven fabric layer 2, two layers of interwoven mesh cloth with a specification of ...

Embodiment 3

[0056] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention provides a novel container fireproof floor, which includes an aluminum foil layer 1, a lower non-woven fabric layer 2, a lower mesh cloth layer 3, a middle material layer 4, and an upper mesh cloth layer from bottom to top Layer 5, mixing layer, batter layer 6 and PVC layer 7, wherein the thickness of PVC layer 7 is 1-2mm

[0057] Its manufacturing method is:

[0058] (1) Prepare a plate-shaped mold, and lay soft foil of the same size in it as the aluminum foil layer 1;

[0059] (2) Prepare a non-woven fabric with a grammage of 14 grams as the lower non-woven fabric layer 2, and evenly coat the adhesive on the surface of the aluminum foil layer 1, and lay the lower non-woven fabric layer 2 on the surface of the aluminum foil layer 1;

[0060] (3) On the upper surface of the lower non-woven fabric layer 2, two layers of interwoven mesh cloth with a specification of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com