Circulating water tunnel-based synchronous measuring system for unsteady cavitating flows

A measurement system and field synchronization technology, applied in the fields of water conservancy and hydropower engineering, ship and underwater vehicle engineering, can solve the problem that the density field, motion field and pressure field of cavitation flow cannot be obtained at the same time, and achieve the effect of accurate measurement data

Active Publication Date: 2015-07-29

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF4 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem that the existing single measurement equipment experimental method cannot simultaneously obtain the density field, motion field and pressure field of cavitation flow, and to provide a multi-field synchronous measurement system for unsteady cavitation flow based on circulating water tunnels

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

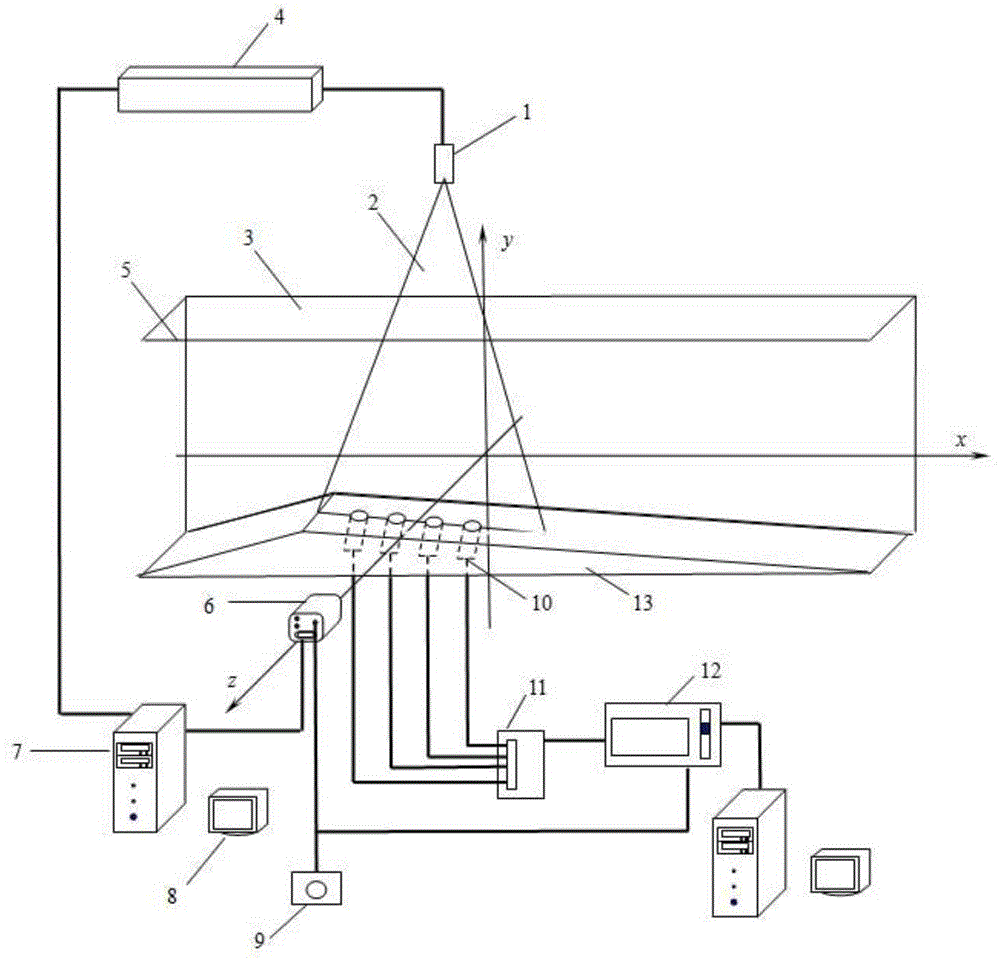

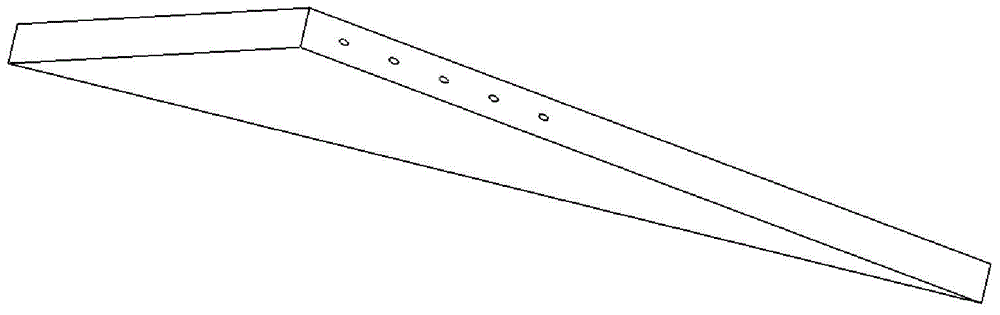

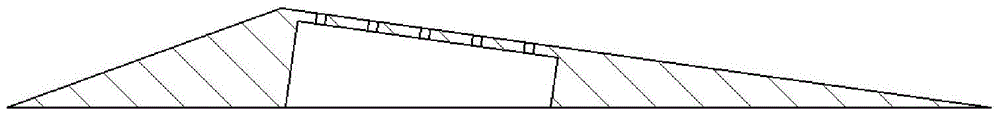

[0026] A multi-field synchronous measurement system for unsteady cavitation flow based on a circulating water tunnel, which consists of four parts: an experimental platform, a particle image velocity measurement subsystem, a pressure measurement subsystem and a synchronous trigger subsystem, such as figure 1 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a circulating water tunnel-based synchronous measuring system for unsteady cavitating flows and belongs to the technical field of marine and underwater vehicle engineering and hydraulic and hydro-power engineering. According to the connectional relation, a laser generator emits laser which is guided to an experimental model though a laser guide arm; the laser guide arm is connected in order with the laser generator and a computer mainframe case; a high-speed camera acquires an image which is transmitted to the computer mainframe case; a pressure sensor acquires a pressure strength signal which is transmitted to another computer through a signal conditioner and a data acquisition card; the top of an experimental segment is provided with transparent organic glass; a synchronous trigger switch controls the high-speed camera and the data acquisition card at the same time. The system has the advantages that various experimental measurement devices are enabled to synchronously observe and measure a cavitating flow field and finally, the unsteady cavitation process, which is complex multi-field coupling flow, is comprehensively researched on.

Description

technical field [0001] The invention relates to a multi-field synchronous measurement system for unsteady cavitation flow based on a circulating water tunnel, and belongs to the technical fields of ship and underwater vehicle engineering and water conservancy and hydropower engineering. Background technique [0002] In high-speed water flow, when the pressure at a certain location drops below the saturated vapor pressure, cavitation will occur. Cavitation flow is accompanied by complex unsteady flow characteristics such as cavity growth and collapse. Such phenomena will have many adverse effects on hydraulic machinery, such as surface material damage, vibration and noise, and power loss. [0003] In the past few decades, there have been many experimental studies on cavitation phenomena. The research equipment mainly includes high-speed camera technology, particle velocimetry technology PIV and laser Doppler velocimetry LDV laser-induced fluorescence LIF and micro sensors. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M10/00

Inventor 王国玉陈广豪张敏娣黄彪高远刘涛涛

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com