Method for enhancing novel wet purification effects of semi-water gas

A semi-water gas, wet purification technology, applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve the problems of harsh control conditions, rising tower blockage resistance, high catalyst consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

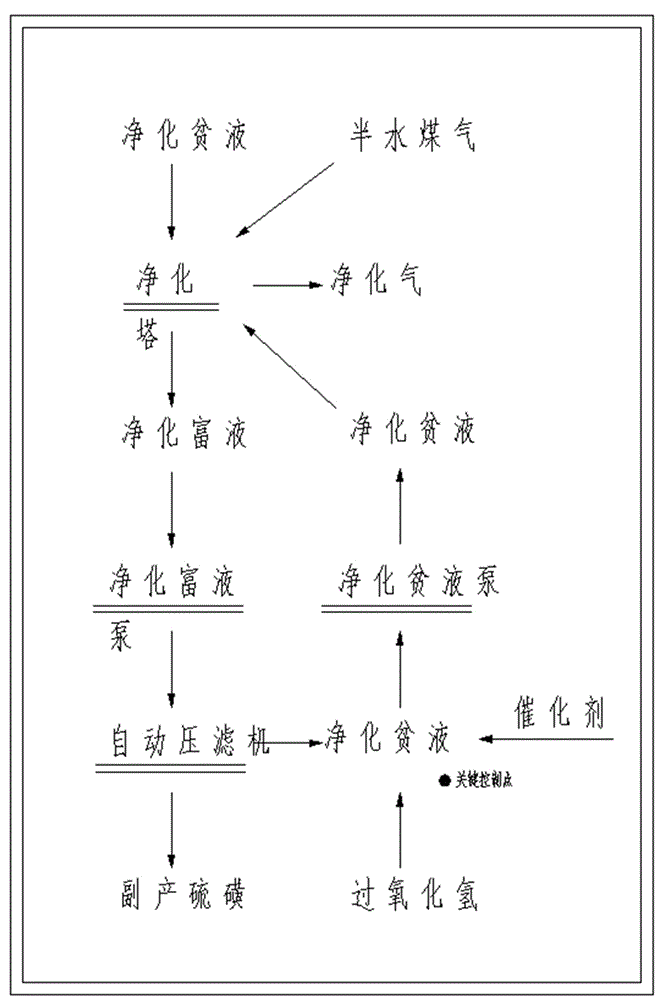

Image

Examples

Embodiment Construction

[0020] The present invention is further described below:

[0021] The invention relates to a method for strengthening the new wet purification effect of semi-water gas, which is characterized in that: the semi-water gas containing sulfides such as hydrogen sulfide enters from the bottom of the purification tower, and the purified lean liquid is pumped from the lean liquid to the liquid distribution The liquid passing through the distributor is evenly sprayed between the packings of the purification tower to form a large-area liquid phase film. When the semi-water gas passes through the packing and contacts the liquid film, the hydrogen peroxide in the liquid will desorb under the action of the catalyst. In addition to the reaction of hydrogen sulfide and organic sulfur, the sulfide content of the purified semi-water gas meets the standard requirements, and enters the subsequent section through the outlet at the top of the tower for processing.

[0022] The purified lean liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com