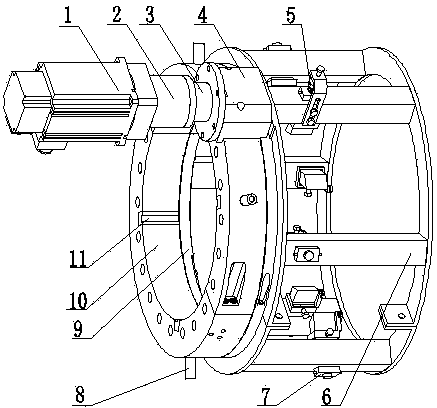

Mouse cage type external anticorrosion coating stripping device of steel pipeline

A squirrel-cage, anti-corrosion layer technology is applied in the field of rapid removal/stripping devices for the outer anti-corrosion layer of steel pipelines, which can solve the problems of low operation efficiency, high labor intensity, poor removal effect, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

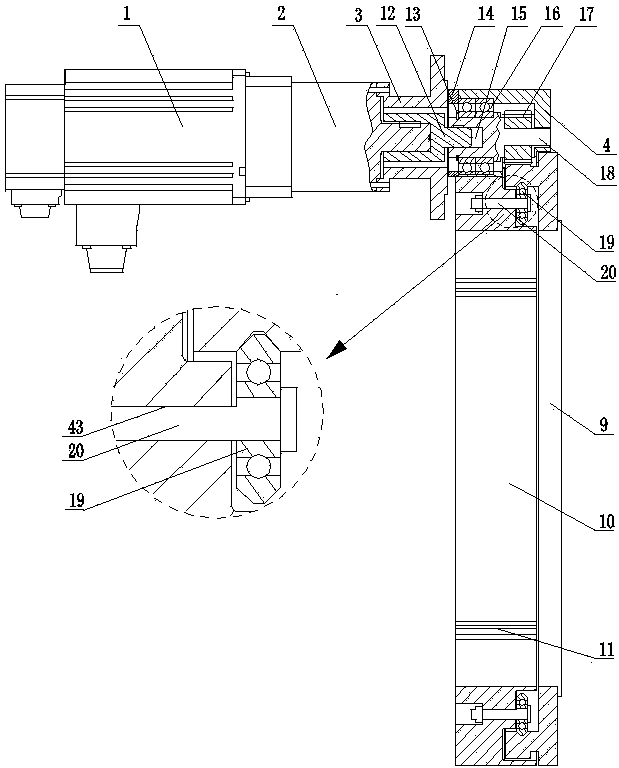

specific Embodiment 1

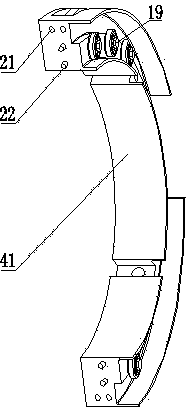

[0033] Before installing the squirrel-cage type steel pipe outer anti-corrosion layer stripping device, each floating type stripping knife 5 is installed on the two semicircle members 45 of the squirrel cage type knife holder 6 in advance, and then the two semicircle members 45 are passed through the positioning pins 27 and screws are respectively connected and fixed to the two semicircular members 41 corresponding to the fixed ring 10; the motor or hydraulic motor 1, the reducer 2, the transmission shaft conversion joint 12, and the conversion flange 3 are fixed in advance through bolt connection.

[0034] When installing the squirrel-cage type steel pipe outer anti-corrosion layer stripping device on the pipeline to be stripped of the anti-corrosion layer, first set the two semicircular members 41 of the fixed ring 10 on the pipeline to be stripped of the anti-corrosion layer through the fixed ring connection positioning pin 27 On both sides, connect and fix the two semicircu...

specific Embodiment 2

[0038] If the device is ready to strip multiple anti-corrosion layers on a pipeline, after the previous one is stripped off, you only need to loosen the block bolt 8, then move the device directly to the next position, and then adjust the block bolt 8 , After ensuring that the fixed ring 10 is coaxial with the pipeline, the next chip cutting operation can be started after locking the 4 block bolts 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com