Offshore wind power generating set and installation method thereof

A wind turbine and wind direction technology, which is applied in the direction of wind motor combination, wind engine, wind power generation, etc., can solve the problems of insufficient wind energy capture, large distance from wind turbines, poor stability, etc., achieve shallow draft, reduce installation difficulty, Ease of Migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

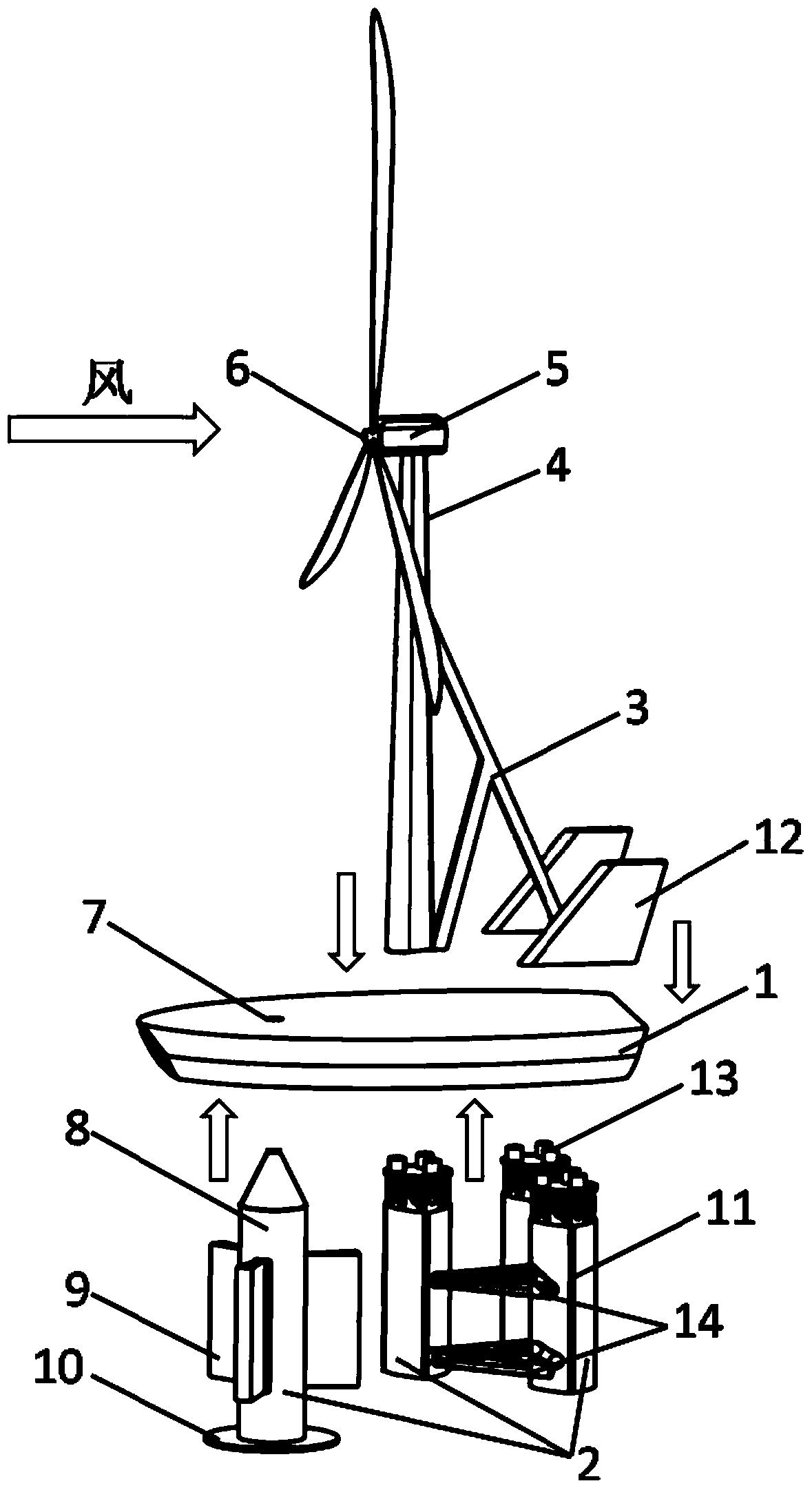

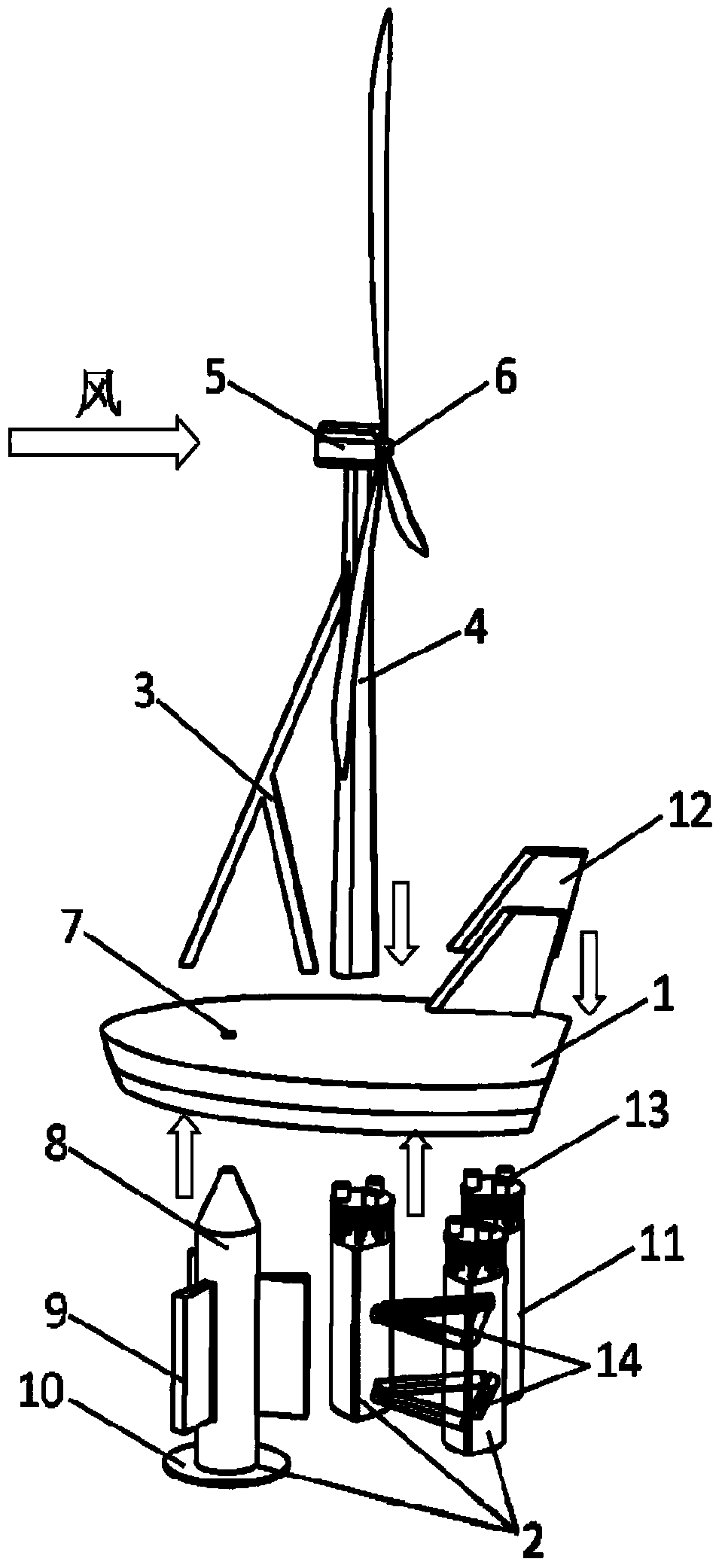

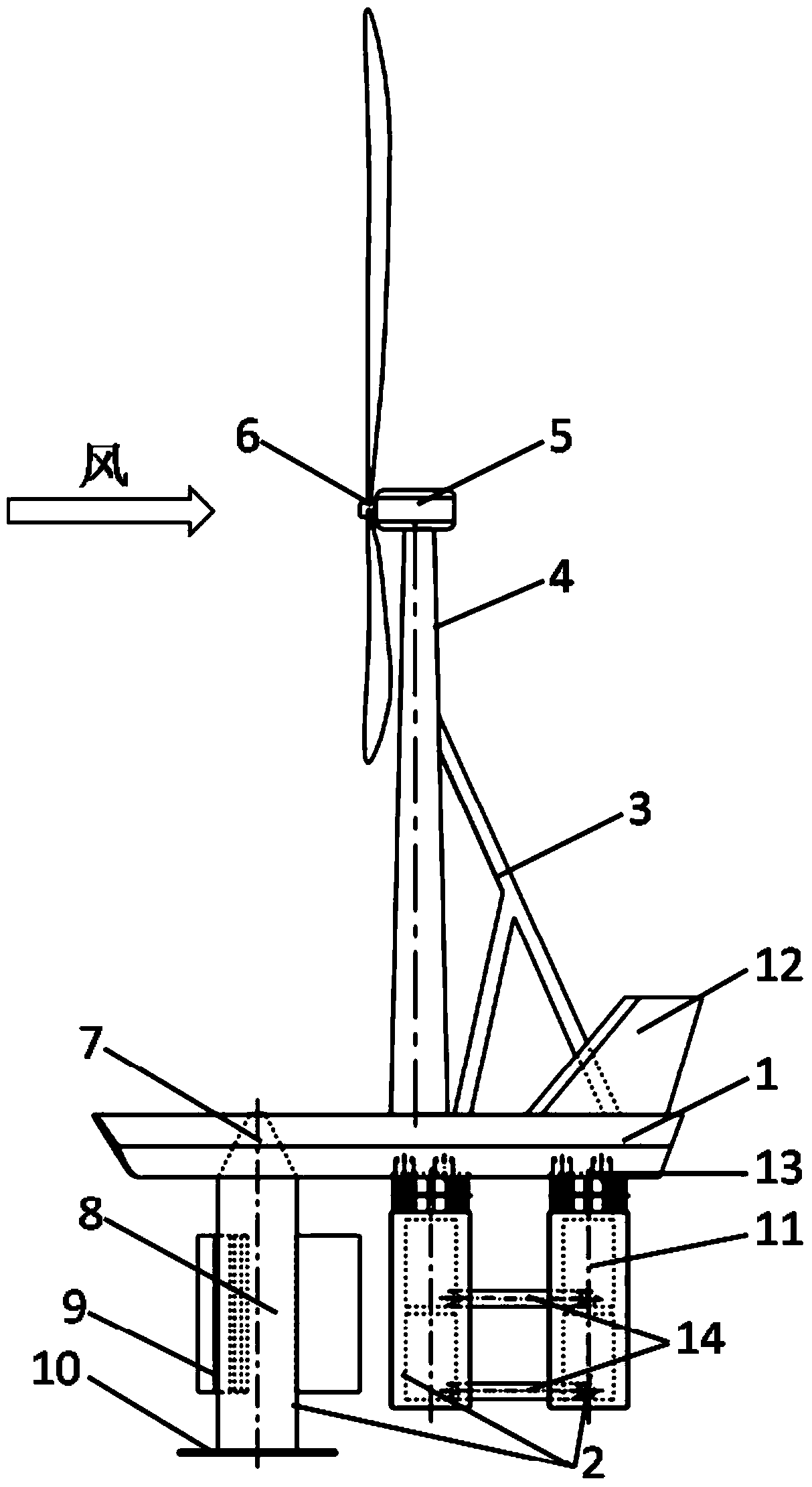

[0038] The present invention will be further described below in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure and assembly method of the present invention in a schematic manner.

[0039] Such as figure 1 , 2 , 3, and 4, the boat platform 1 adopts a flat-bottomed barge structure, and a yaw cone slewing bearing 7 is installed on the front part (windward side) of the boat platform 1; a tower is fixed behind the yaw cone slewing bearing 7. The frame 4 and the cross section of the tower frame 4 adopt shapes such as drop shape, oval shape or ellipse shape with small wind resistance, and are rigidly connected with the nacelle of the wind power generating set. When the impeller 6 is arranged in the upwind direction in front of the tower 4, as figure 1 , 3 , the diagonal brace 3 is installed on the leeward side of the tower 4; when it is arranged in the downwind direction behind the tower 4, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com