Underwater self suction injection stream flow characteristic integrated test device system

A technology of flow characteristics and testing device, applied in the field of water jet, can solve the problems of increasing the volume of the pressure water tank, increasing the manufacturing cost and operation difficulty, affecting the suction volume of the nozzle and the self-suction performance, etc., so as to improve the impact performance, Good suction effect and good energy gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

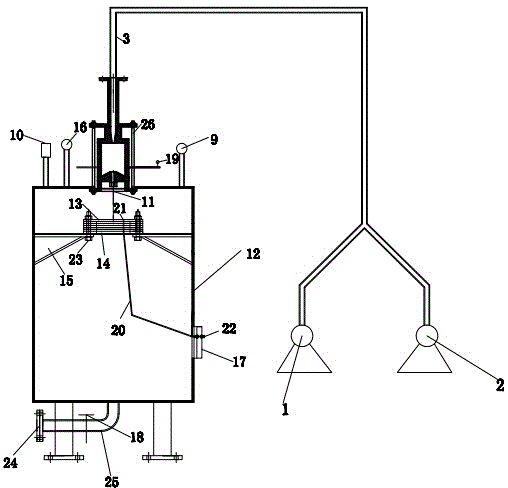

[0033]The core of the present invention is to provide an integrated test device system for jet flow characteristics of underwater self-suction nozzles, which can realize submerged jet flow under the drive of working pump 1 and booster pump 2; 12, the volume of the pressurized water tank 12 can be greatly reduced, the operation is simple, and the manufacturing cost can be saved; the jet intensity and confining pressure can be adjusted by adjusting the power of the working pump 1 and the opening of the drain valve 18; the overall processing material is plexiglass , can observe, photograph and test the gas-liquid two-phase flow characteristics inside the nozzle and the impact characteristics of the nozzle gas-liquid two-phase jet flow in real time; when the diameter of the pressurized water tank 12 is greater than or equal to 50cm, its side wall has little influence on the jet flow, which can be approximated by real simulation Submerges the jet while saving material.

[0034] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com