Micro integrated three-dimensional farm

A three-dimensional, farm technology, applied in climate change adaptation, container cultivation, horticulture, etc., can solve the problems of restricting the development of facility agriculture, high selection of vegetable varieties, complex systems, etc., to improve urban microclimate and building thermal environment, management Maintain the effect of low technology and low knowledge and skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

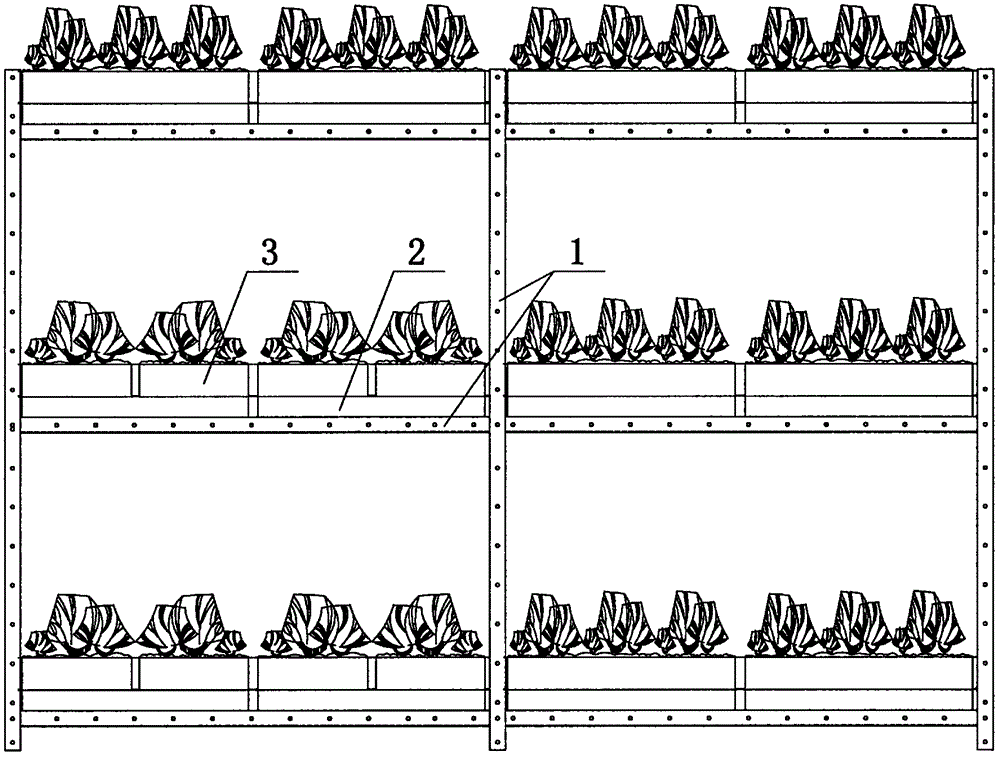

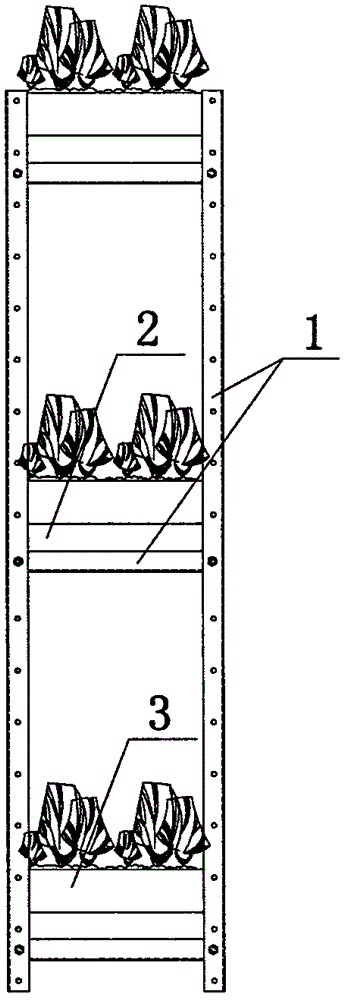

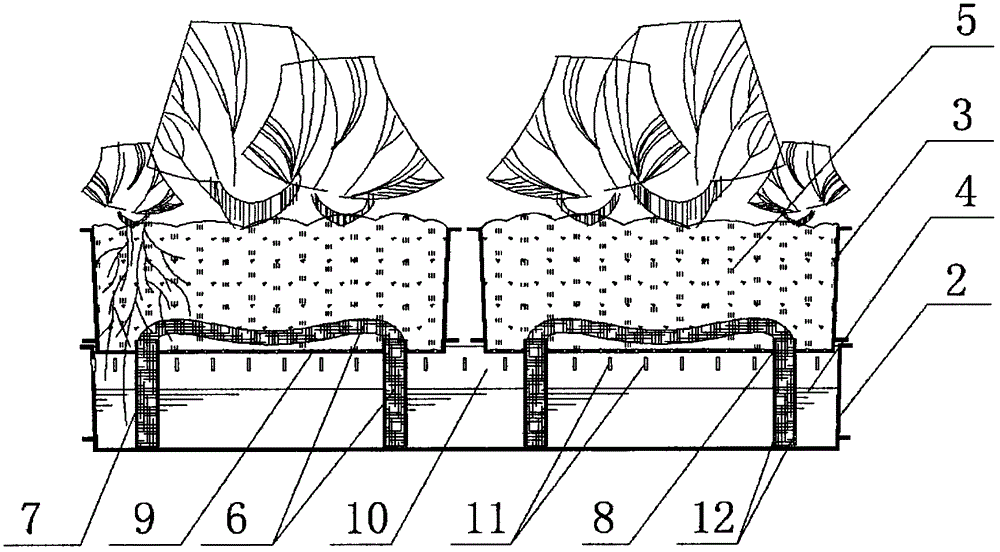

[0016] Such as figure 1 As shown, the main body of the present invention is composed of a load-bearing frame 1, a water storage tray 2, and a planting tray 3. The load-bearing frame 1 is made of metal or other profiles and can be assembled into a multi-layer frame structure. The load-bearing frame 1 can bear the The load of the planting module, a set of water storage tray 2, planting tray 3 and their contents constitute a single planting module. Such as figure 2 As shown, the distance between each layer of the load-bearing frame 1 can be adjusted according to the geographical location, the size of the water storage tray 2 and the planting tray 3, so that the plants planted in each layer of the planting tray 3 can obtain enough light. Such as image 3 As shown, the planting tray 3 is filled with planting soil 5, the water storage tray 2 stores water 4 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com