New type mixer power transmission mechanism

A technology of power transmission mechanism and mixer, which is applied to mixer accessories, mixers, mixers with rotating containers, etc., can solve the problems of obvious transmission mechanism noise, large load of mixing tank, and difficult process, and improve humanized design. , Improve the service life of the equipment and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

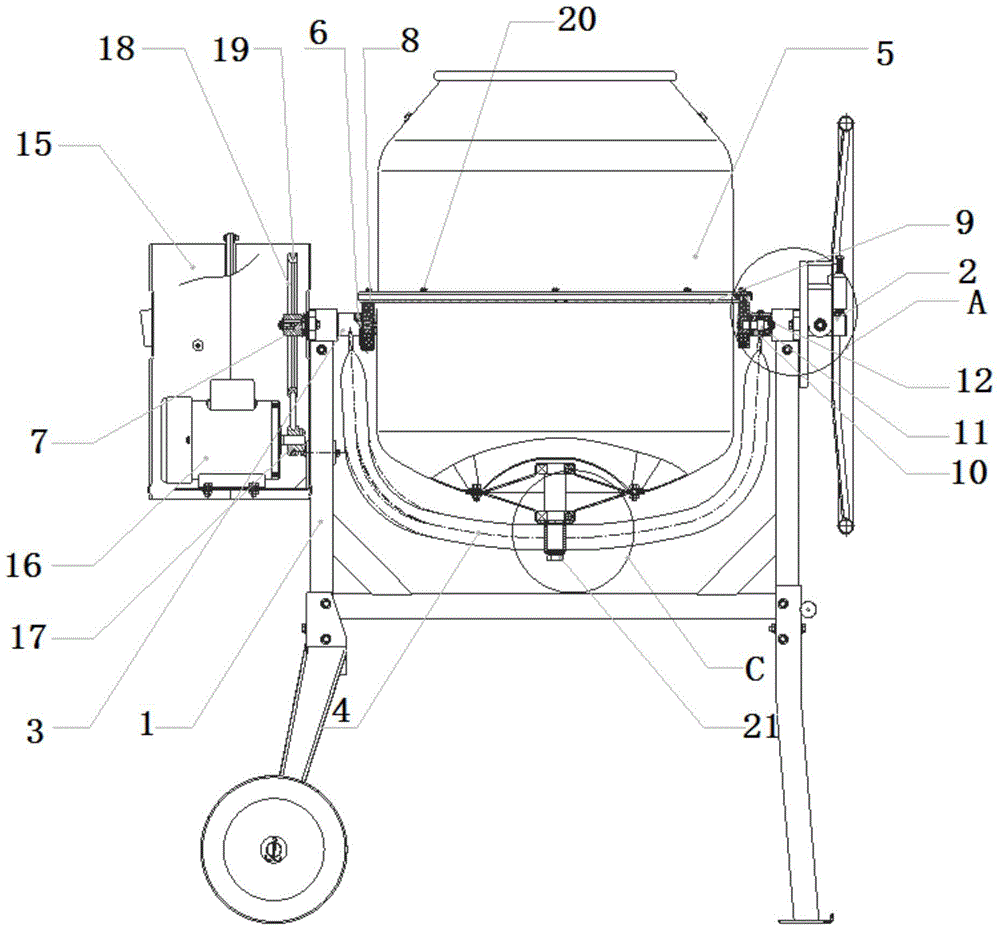

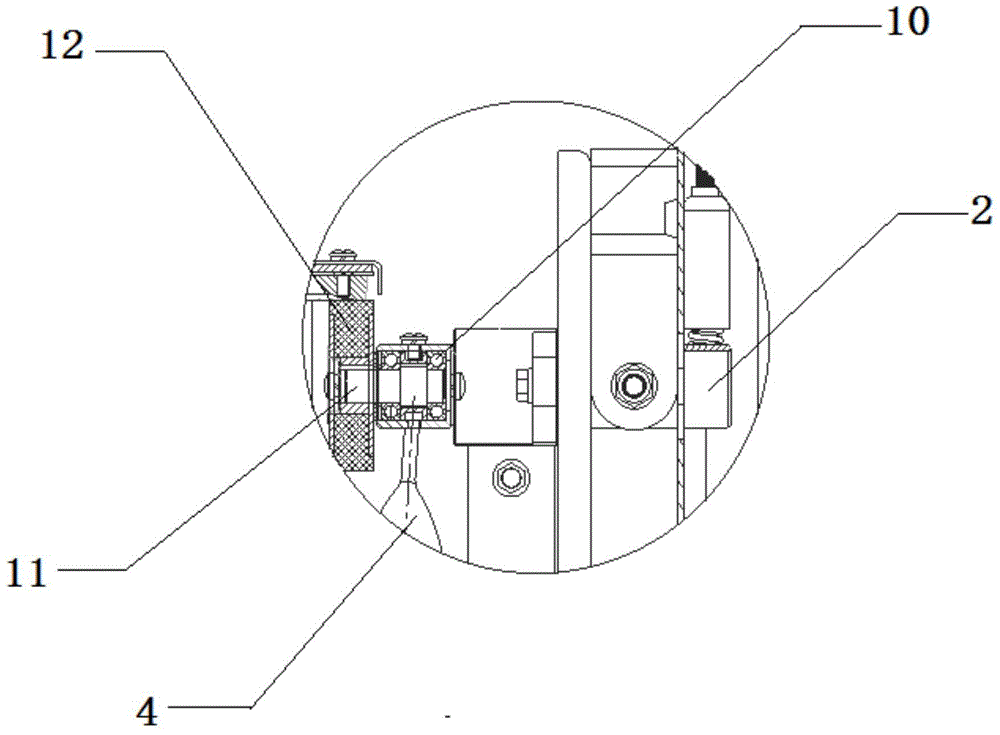

[0027] Embodiment 1: refer to figure 1 As shown, a new mixer power transmission mechanism includes a mounting bracket 1, a branch pipe 2 and a bearing seat 3 symmetrically fixed on the mounting bracket 1, a U-shaped bracket 4 fixedly connected to the branch pipe 2 and the bearing seat 3 at both ends, and the bottom The mixing pot body 5 that is connected with the U-shaped support 4 and can rotate freely, the driving device that is located on the mounting bracket 1, the supporting device that is located on the branch pipe 2, and the two bearings 6 that are fixed on the bearing seat 3, are set on two The main shaft 7 in the bearing 6, the friction wheel 8 fixedly connected with the output end of the main shaft 7, and the friction belt 9 fixed on the outer peripheral side of the stirring pot body 5; the output end of the driving device is connected with the input end of the main shaft 7, and the friction wheel One 8 and the supporting device are all connected with the friction...

Embodiment 2

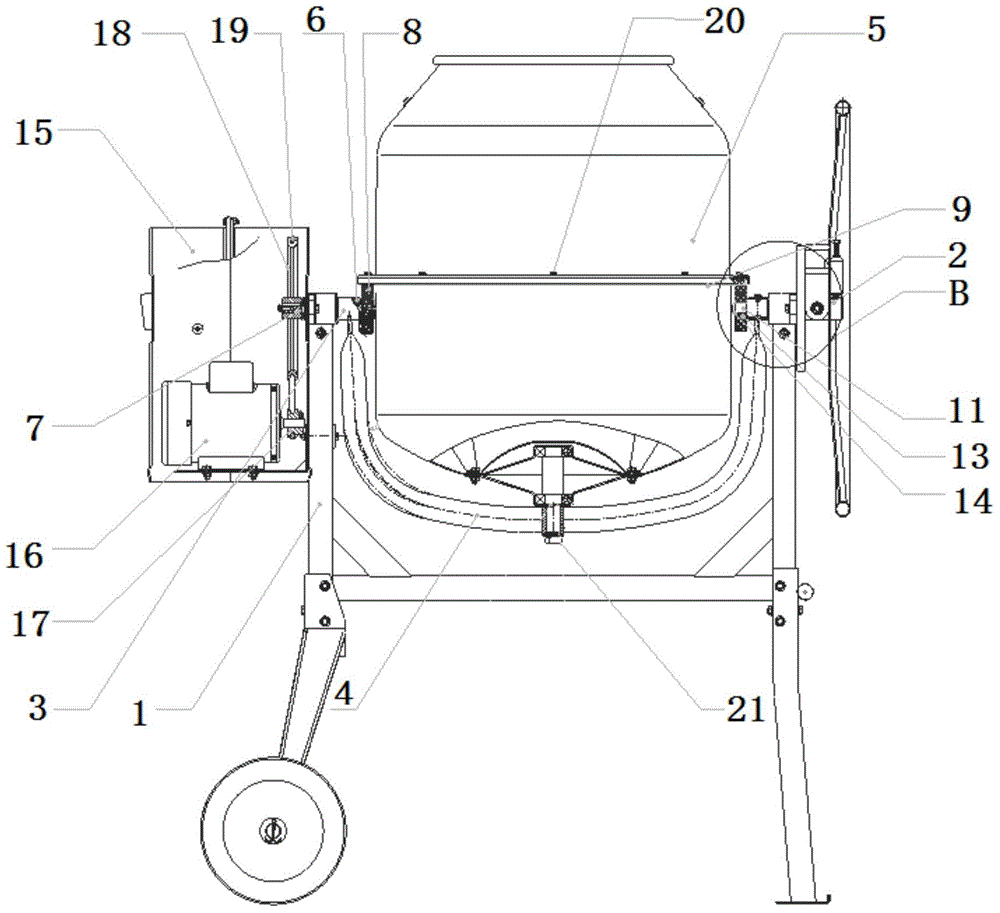

[0032] refer to figure 2 , 4 As shown, the main difference between the technical solutions of embodiment 2 and embodiment 1 is that the supporting device of the present invention includes a sub-shaft 11 fixed on the branch pipe 2, and a supporting wheel 13 which is arranged on the output end of the sub-shaft 11 and can rotate freely. , On the secondary shaft 11, a retaining ring 14 is arranged on the outside of the support wheel 13, and the support device plays a supporting and guiding role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com