Apparatus for boring hole in steel tube

A steel pipe and drill bit technology, which is applied in the field of metal product processing machinery, can solve problems such as the drilling of metal pipes with different diameters, the concave area of the upper hole of the metal pipe, and the impact on the quality of the metal pipe, so as to prevent subsidence and ensure the processing quality. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

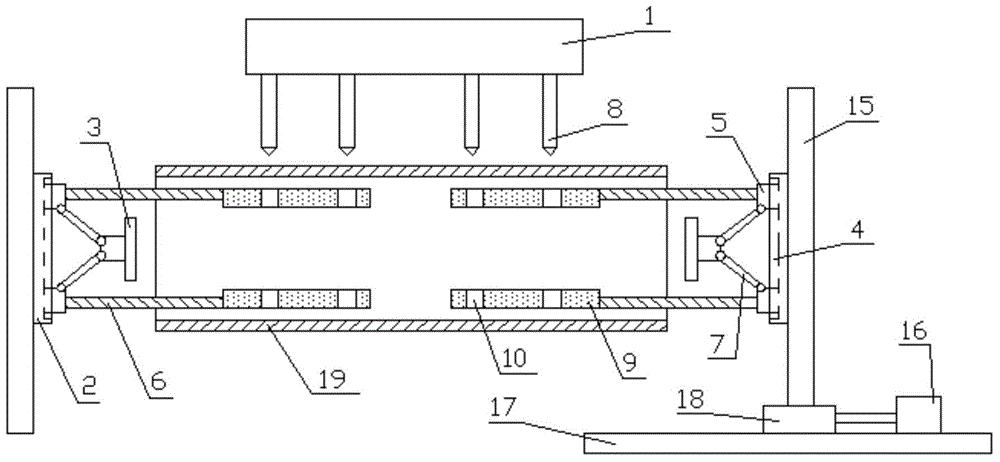

[0038] combine figure 1 : A device for drilling steel pipes, comprising a drilling unit 1 and at least one supporting unit;

[0039] The support unit includes a support plate 2 and a hydraulic cylinder 3. The support plate 2 is provided with a first chute 4, and the first chute 4 is provided with two first sliders 5, and each first slider 5 has a There is a support plate 6, two support plates 6 are arranged parallel to each other, and the two first sliders 5 are connected to the hydraulic cylinder 3 through a connecting rod 7 of equal length;

[0040] Drilling unit 1 comprises several drill bits 8, and the extension direction of this drill bit 8 is perpendicular to the direction that support plate 6 extends, and this drill bit 8 is distributed along the extension direction of support plate 6, and the horizontal distance between this drill bit 8 and two support plates 6 Equal, otherwise, drill bit 8 can not carry out drilling along the radial direction of steel pipe 19.

[00...

Embodiment 2

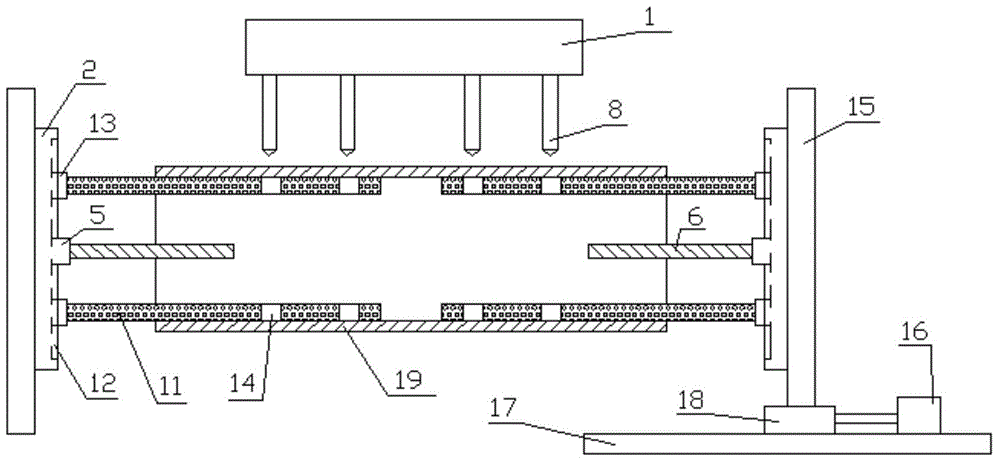

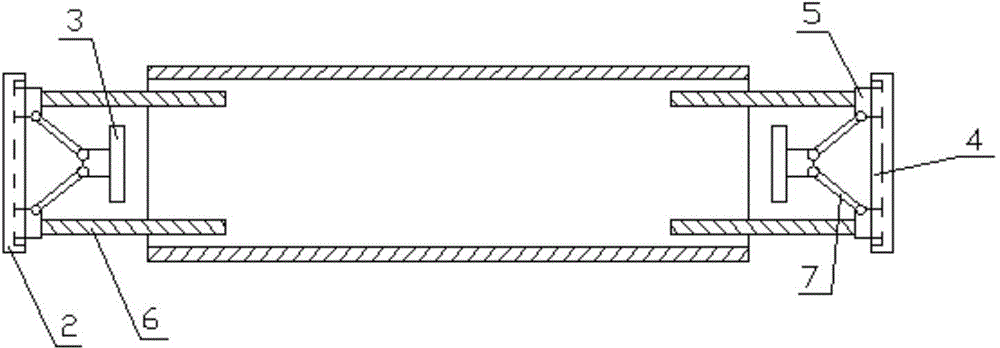

[0056] combine figure 2 , 3 , 4: A device for drilling steel pipes, including a drilling unit 1 and at least one supporting unit;

[0057] The support unit includes a support plate 2 and a hydraulic cylinder 3. The support plate 2 is provided with a first chute 4, and the first chute 4 is provided with two first sliders 5, and each first slider 5 has a There is a support plate 6, two support plates 6 are arranged parallel to each other, and the two first sliders 5 are connected to the hydraulic cylinder 3 through a connecting rod 7 of equal length;

[0058] Drilling unit 1 comprises several drill bits 8, and the extension direction of this drill bit 8 is perpendicular to the direction that support plate 6 extends, and this drill bit 8 is distributed along the extension direction of support plate 6, and the horizontal distance between this drill bit 8 and two support plates 6 Equal, otherwise, drill bit 8 can not carry out drilling along the radial direction of steel pipe 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com