System and method for controlling master and slave teleoperation of robot arm force reflecting telepresence

A technology of remote operation control and control system, applied in the direction of manipulators, manufacturing tools, etc., can solve the problem that the position error cannot be eliminated between the master and slave hands, affect the operation performance of the system, and the impact of the master robot, so as to enhance the sense of presence, flexible movement, Ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

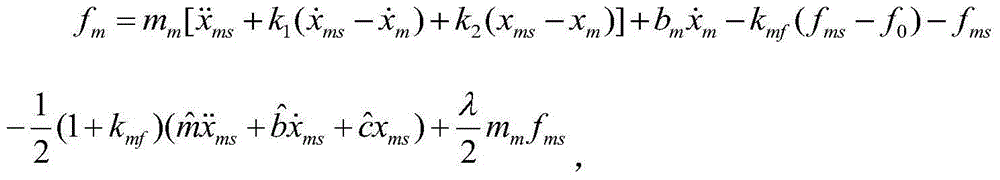

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

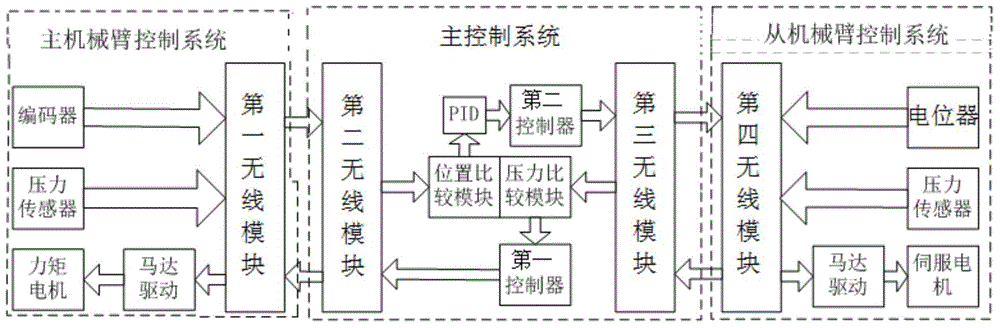

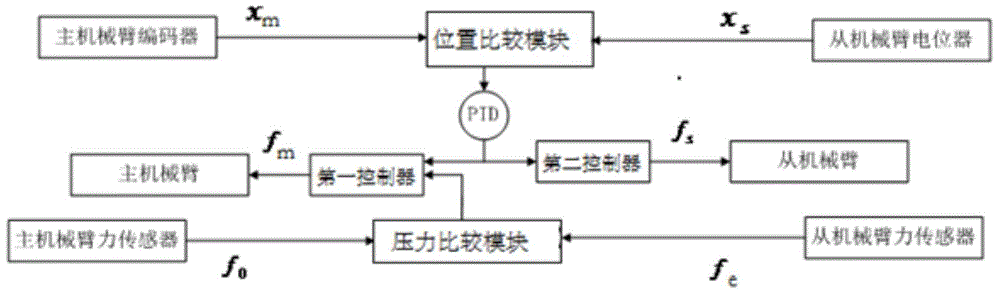

[0036] Such as figure 1 As shown, a master-slave teleoperation control system with telepresence of force sense of a manipulator includes a master manipulator control system, a master control system and a slave manipulator control system, wherein:

[0037] The main mechanical arm control system includes an encoder, a pressure sensor, a torque motor, a motor driver and a first wireless module, the encoder is connected to the first wireless module, the first wireless module is connected to the motor driver, and the motor driver is connected to the installation The torque motors at each joint of the main manipulator are connected with the pressure sensor installed on the main manipulator by the first wireless module;

[0038] The control system of the slave manipulator includes a potentiometer, a pressure sensor, a servo motor, a motor driver and a fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com