Automobile rearview mirror and manufacturing method thereof

A technology of automobile rearview mirror and manufacturing method, which is applied in the field of automobile rearview mirror, can solve the problems of plastic rearview mirror not being resistant to grit impact, easy to have scratches and imaging on the mirror surface, increasing the weight of rearview mirror assembly, etc. Imaging clarity, not easy to break, meet the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

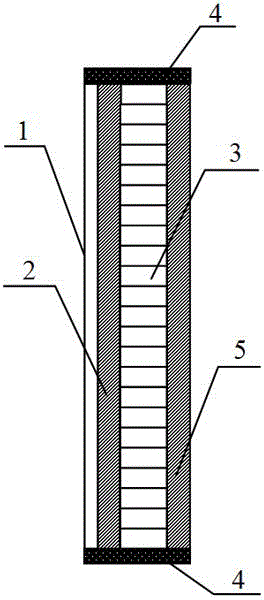

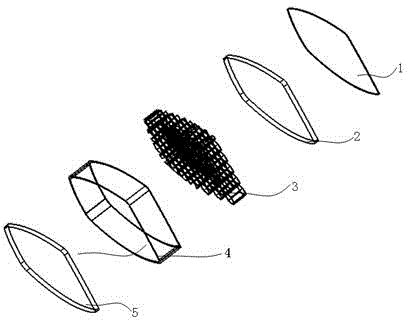

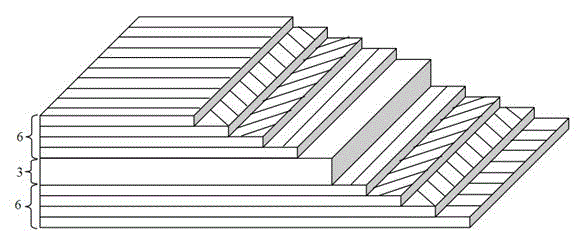

[0041] The present embodiment provides an automobile rearview mirror and a method for preparing the rearview mirror, comprising the following steps: adopting a thermal expansion coefficient of 5×10 -6 ppm·℃ -1 The glass is used as the mold material, and the mold is made according to the curvature and size of the car rearview mirror. The mold is cleaned with acetone dipped in non-woven fabric. After cleaning, let it dry naturally. Let it air for 10 minutes and then wipe it evenly with a non-woven fabric dipped in mold release wax. After airing for 10 minutes, take another clean non-woven fabric to wipe the surface of the mold to remove excess mold release wax, and then follow [0 / 45 / -45 / 90 / C 0.6 ] s Lay 3K unidirectional carbon cloth and reinforcing felt with a thickness of 0.6mm. After laying, lay down demoulding cloth, diversion net and diversion pipe in sequence according to the vacuum bag pressing process, seal with a vacuum bag and connect the vacuum pump. HR-196 resin...

Embodiment 2

[0043] The present embodiment provides an automobile rearview mirror and a method for preparing the rearview mirror, comprising the following steps: adopting a thermal expansion coefficient of 5×10 -6 ppm·℃ -1 The glass is used as the mold material, and the mold is made according to the curvature and size of the car rearview mirror. The mold is cleaned with acetone dipped in non-woven fabric. After cleaning, let it dry naturally. Let it air for 10 minutes and then wipe it evenly with a non-woven fabric dipped in mold release wax. After airing for 10 minutes, take another clean non-woven fabric to wipe the surface of the mold to remove excess mold release wax, and then follow [0 / 45 / -45 / 90 / C 2 ] s Lay 12K unidirectional carbon cloth and aramid honeycomb panels with a thickness of 2mm. After the laying is completed, lay down the demoulding cloth, diversion net and diversion pipe in sequence according to the vacuum bag pressing process. Seal and connect the vacuum pump with a ...

Embodiment 3

[0045] The present embodiment provides an automobile rearview mirror and a method for preparing the rearview mirror, comprising the following steps: adopting a thermal expansion coefficient of 6×10 -6 ppm·℃ -1 The metal is used as the mold material, and the mold is made according to the curvature and size of the car rearview mirror. The mold is cleaned with acetone dipped in non-woven fabric. After cleaning, let it dry naturally. Let it air dry for 10 minutes and wipe it evenly with a non-woven fabric dipped in mold release agent, then follow [0 / 45 / -45 / 90 / C 2 ] s A 12K unidirectional carbon cloth and a reinforcing felt with a thickness of 2 mm were placed in the mold in turn. After the placement, HR-8300 resin was introduced at 0.15 MPa according to the RTM process, and cured at 130 °C for 2 hours. After curing, demould, take out the carbon fiber sandwich composite board, cut off the leftovers by water cutting, and then use 600 and 800 grit water sandpaper to polish one sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com