A kind of highly wear-resistant glazed ceramic brick and its preparation method

A technology of high wear-resistant and painted pottery, which is applied in the field of high wear-resistant in-glaze ceramic products and its preparation. It can solve the problems of easy wear, hardness, and poor wear resistance, and achieve good air permeability, high wear resistance, and The effect of transparent glaze layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing high-wear-resistant in-glaze ceramic tiles, the method comprising:

[0025] After inkjet printing or roller printing decoration according to the existing antique brick technology, use a bell jar or a linear glazer to pour a layer of transparent glaze containing 10-60% of high wear-resistant transparent frit particles, and then polish it to get the original product.

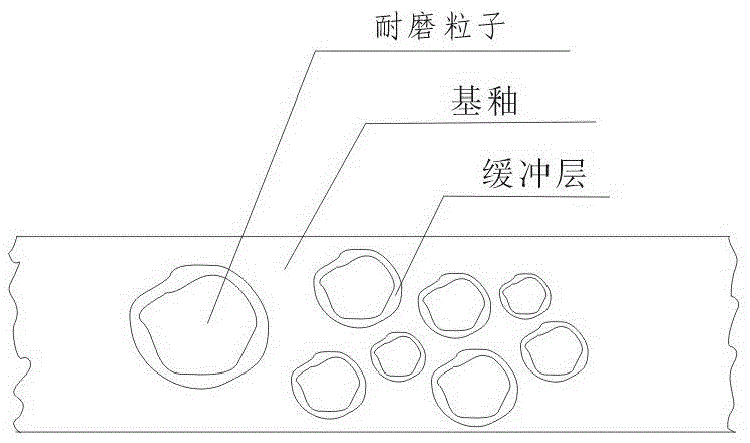

[0026] As a glass phase, the transparent base glaze is filled between the pores of the high-temperature and high-wear-resistant transparent frit particles, and reacts with it to form a well-bonded buffer layer, which will not peel off during the polishing process. Its chemical composition: SiO 2 55~65%, Al 2 o 3 16~20%, CaO8~15%, MgO1~3%, K 2 O1~4%, Na 2 O3-5%, ZnO0-5%. Fineness 325 mesh sieve remaining 0.4 ~ 0.8%.

[0027] Chemical composition of high wear-resistant transparent frit particles: SiO 2 52~58%, Al 2 o 3 25~30wt%, CaO8~15%, MgO0.2~0.5%, K ...

Embodiment 1

[0035] After ink-jet printing or roller printing decoration according to the existing antique brick technology, a layer of transparent glaze containing 10-60% of high-wear-resistant transparent frit particles is sprayed with a linear glazer, fired at a high temperature of 1200 ° C, and finally This product is obtained by polishing.

[0036] Specific steps are as follows:

[0037] 1) Preparation of wear-resistant particles: high wear-resistant transparent frit particles (SiO 2 52~58%, Al 2 o 3 25~30wt%, CaO8~15%, MgO0.2~0.5%, K 2 O1~3%, Na 2 O0.5~2%, ZnO1~5%) crushed and sieved, crushed to 130~180 mesh;

[0038] 2) Preparation of transparent base glaze: the transparent glaze (SiO 2 55~65%, Al 2 o 3 16~20%, CaO8~15%, MgO1~3%, K 2 O1~4%, Na 2 O3~5%, ZnO0~5%) ball milling, control fineness 325 mesh sieve remaining 0.4~0.8%;

[0039]3) Preparation of suspending agent: sodium carboxymethylcellulose 50%, ethylene glycol 20%, polyethylene glycol 30%;

[0040] 4) Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com