Lubricating oil for diesel engines

A lubricating oil and diesel engine technology, applied in the field of lubricating oil, can solve the problems of reduced PM removal efficiency, shortened DPF life, reduced ash content, etc., and achieves the effects of reducing environmental burden, good cleaning and dispersibility, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

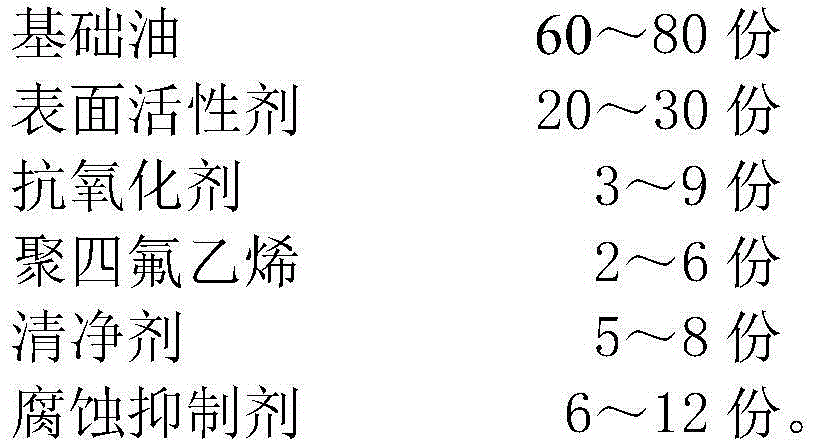

[0021] Take the following raw materials by weight (mix evenly):

[0022]

[0023] The above-mentioned base oils are Class II lubricating oil base oils classified according to API.

[0024] The above surfactant preparation method: weigh 13 parts by weight of alkyl glucoside, 7 parts by weight of tea saponin and 23 parts by weight of sulfated castor oil, and mix them evenly.

[0025] The above antioxidant preparation method: weigh a mixture of 20 parts by weight of p-diisooctyl diphenylamine and 23 parts by weight of 2,6-di-tert-butyl-4-methylphenol, and mix evenly.

[0026] The preparation method of the above detergent: weigh the mixture of 18 parts by weight of polyisobuteneamine and 18 parts by weight of polyetheramine, and mix them evenly.

[0027] The preparation method of the above-mentioned corrosion inhibitor: weigh a mixture of 15 parts by weight of 2,4-di-tert-butylphenol and 21 parts by weight of methyl isobutyrate, and mix evenly.

Embodiment 2

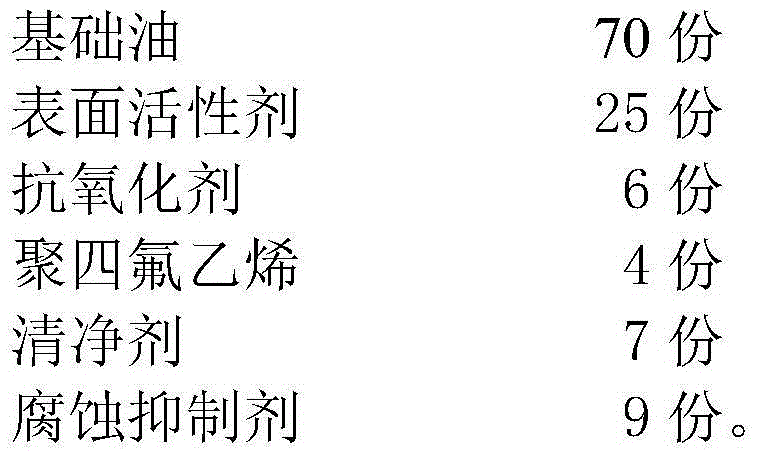

[0029] Take the following raw materials by weight (mix evenly):

[0030]

[0031] The above-mentioned base oils are Class I lubricating oil base oils classified according to API.

[0032] The above surfactant preparation method: weigh 10 parts by weight of alkyl glucoside, 5 parts by weight of tea saponin and 25 parts by weight of sulfated castor oil, and mix them evenly.

[0033] The above antioxidant preparation method: weigh a mixture of 22 parts by weight of p-diisooctyl diphenylamine and 20 parts by weight of 2,6-di-tert-butyl-4-methylphenol, and mix evenly.

[0034] The preparation method of the above-mentioned detergent: weigh a mixture of 20 parts by weight of polyisobutylene amine and 15 parts by weight of polyetheramine, and mix them evenly.

[0035] The preparation method of the above corrosion inhibitor: weigh a mixture of 12 parts by weight of 2,4-di-tert-butylphenol and 24 parts by weight of methyl isobutyrate, and mix them evenly.

Embodiment 3

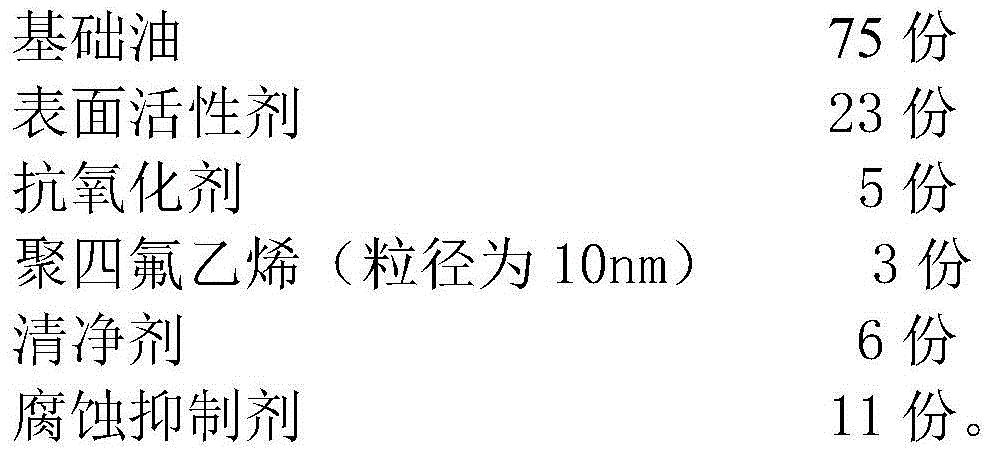

[0037] Take the following raw materials by weight (mix evenly):

[0038]

[0039] The above-mentioned base oils are Class I lubricating oil base oils classified according to API.

[0040] The above surfactant preparation method: weigh 15 parts by weight of alkyl glucoside, 8 parts by weight of tea saponin and 20 parts by weight of sulfated castor oil, and mix them uniformly.

[0041] The above antioxidant preparation method: weigh a mixture of 17 parts by weight of p-diisooctyl diphenylamine and 25 parts by weight of 2,6-di-tert-butyl-4-methylphenol, and mix evenly.

[0042] The preparation method of the above-mentioned detergent: weigh the mixture of 15 parts by weight of polyisobutylamine and 20 parts by weight of polyetheramine, and mix them evenly.

[0043] The preparation method of the above corrosion inhibitor: weigh a mixture of 17 parts by weight of 2,4-di-tert-butylphenol and 19 parts by weight of methyl isobutyrate, and mix them evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com