High-pressure water sealing device for heading machine and heading machine

A sealing device and high-pressure water technology, applied in the field of water sealing device and high-pressure water sealing device, can solve the problems of unsatisfactory sealing effect, large assembly space, poor pressure bearing capacity, etc., so as to improve the underground working environment and improve the water sealing effect. , the effect of reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

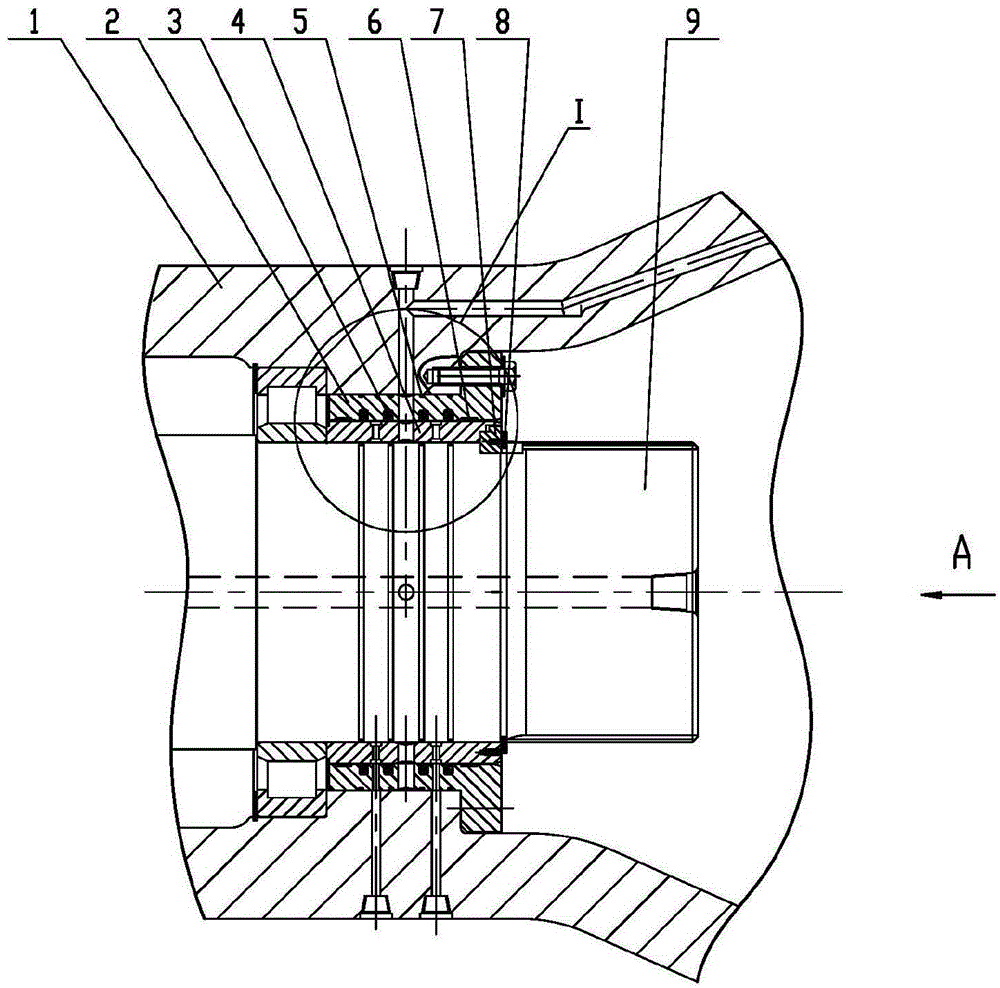

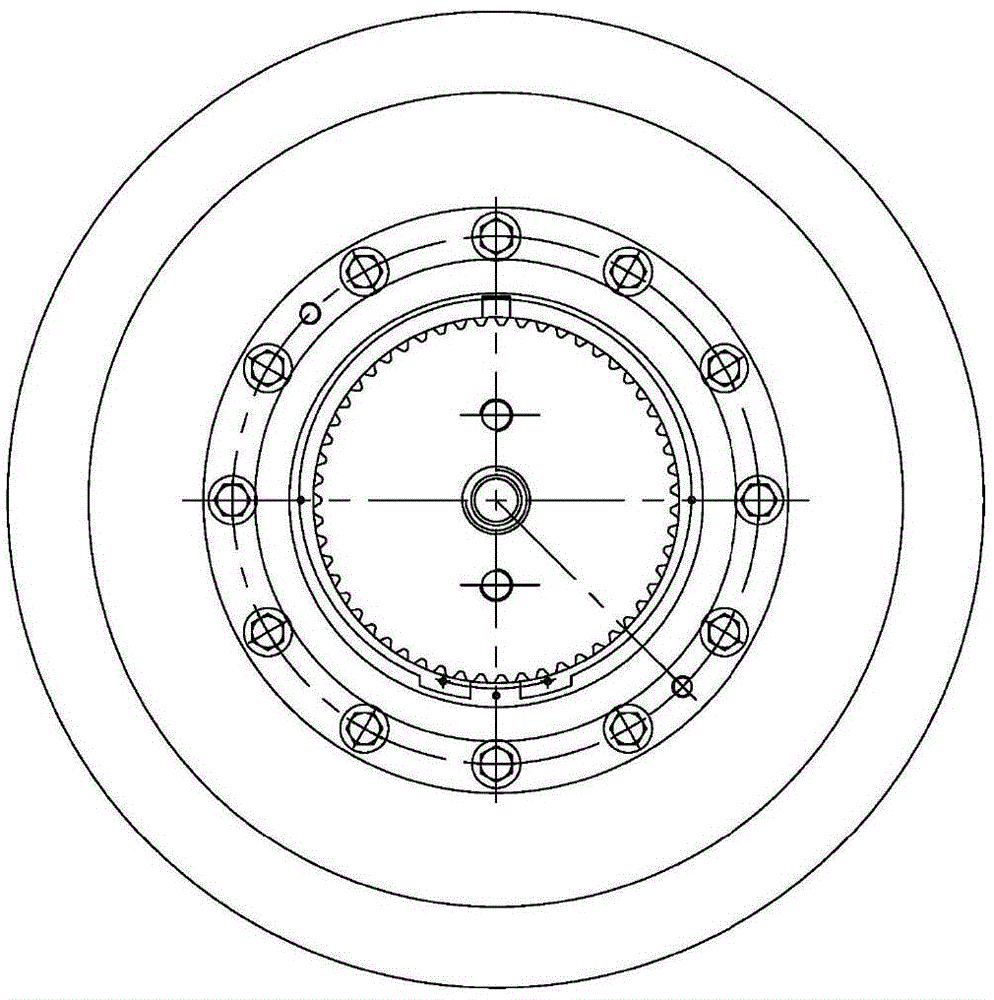

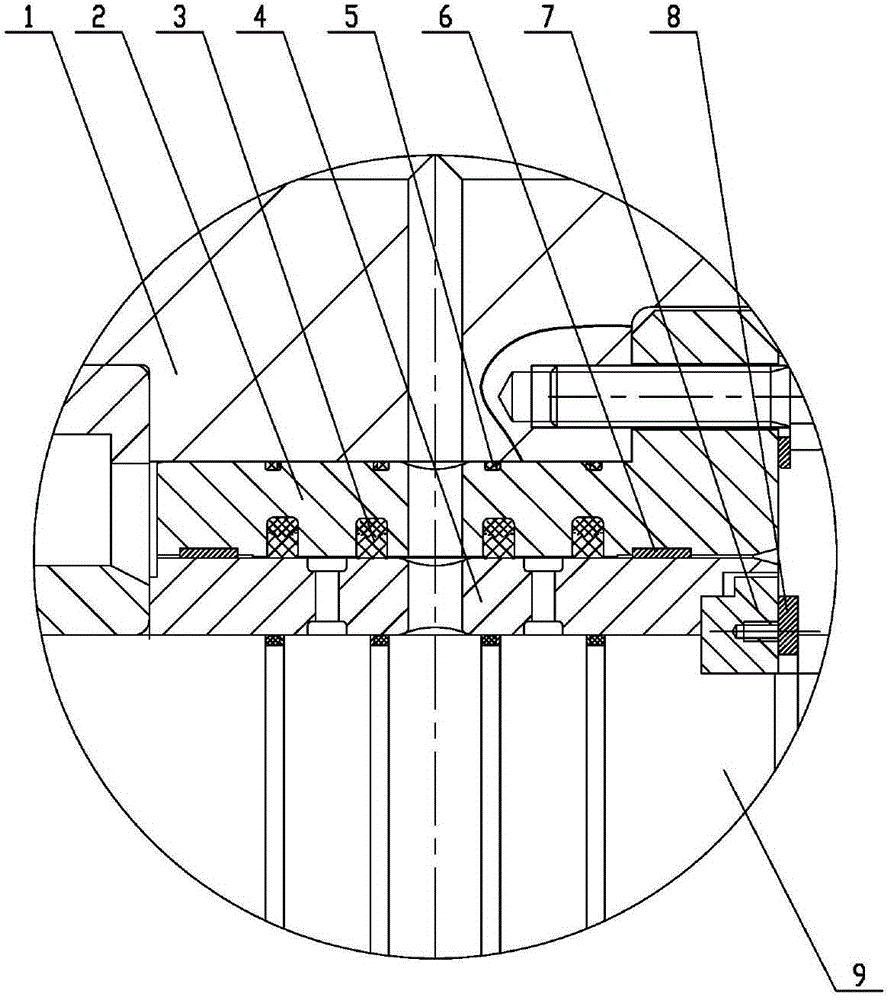

[0020] Such as Figure 1 to Figure 3 As shown, a high-pressure water sealing device for a roadheader and a roadheader include a sealing retaining ring 2, a rotating lattice ring 3, a sealing ring 4, a wear-resistant ring 6, a flat key 7 and a retaining ring 8, and the sealing The baffle ring 2 is fixed on the coupling cylinder 1, the sealing ring 4 is installed on the rotating main shaft 9, and O-rings are installed between the sealing baffle ring 2 and the coupling cylinder 1 and between the sealing ring 4 and the rotating main shaft 9 5; a wear-resistant ring 6 and a rotating grid ring 3 are installed between the sealing retaining ring 2 and the sealing ring 4; there is no relative between the sealing ring 4 and the rotating main shaft 9; The rotating flat key 7 is provided with a groove on the rotating main shaft 9, and a retaining ring 8 is housed in the groove, and on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap