Method for utilizing cooling water of host machine and cooling water of standby machine of power equipment in cascaded way

A power equipment and cooling water technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of large consumption of circulating water, increased operating costs of circulating water systems, and small temperature difference between the inlet and outlet of circulating water, etc. The construction method is simple, the cooling water is prevented from burning out the equipment, and the operation cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

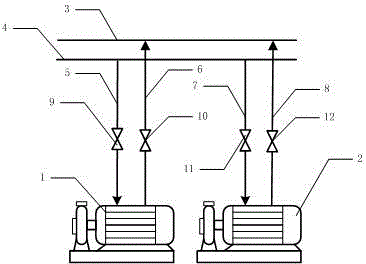

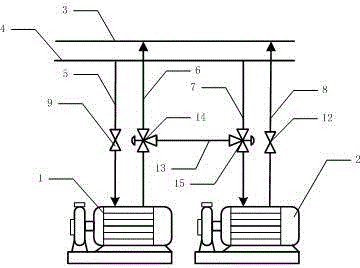

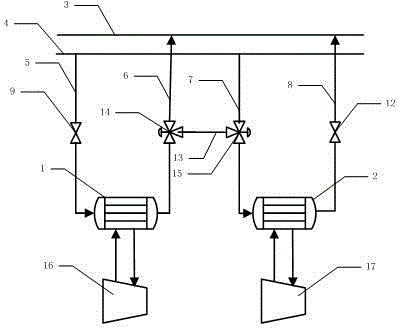

[0025] Embodiment 1: below by the implementation instance in certain oil refinery, in conjunction with attached figure 2 And attached image 3 The present invention is further described.

[0026] There are two sets of light oil fractionation tower bottom pumps in an oil refinery, one is the main power equipment 1, the main power equipment 1 adopts the lubricating oil cooler of the main compressor, one is the main power equipment 1, and the standby power equipment 2 Adopt spare compressor lubricating oil cooler. The original process is that the main power equipment 1 and the main power equipment 1 are connected in parallel to configure circulating cooling water: the main power equipment 1 is connected to the main pipeline through the main power equipment upper water pipe 5 and the main power equipment return water pipe 6, and the main power equipment upper water pipe 5 and the main power equipment are connected to the main pipeline. The equipment return pipe 6 is respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com