A complete set of boiler automatic dust removal equipment

A technology of automatic dust removal and complete sets of equipment, applied in lighting and heating equipment, removal of solid residue, treatment of combustion products, etc., can solve environmental pollution soot blowing equipment and technology, can not fundamentally solve the problem, can not achieve accurate Quantification and other issues to achieve the effect of low labor intensity, reasonable equipment layout and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

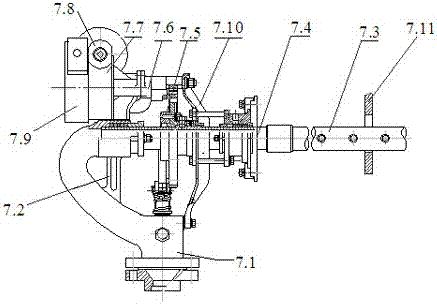

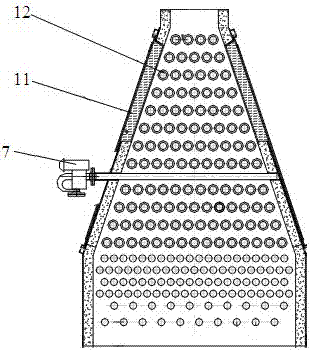

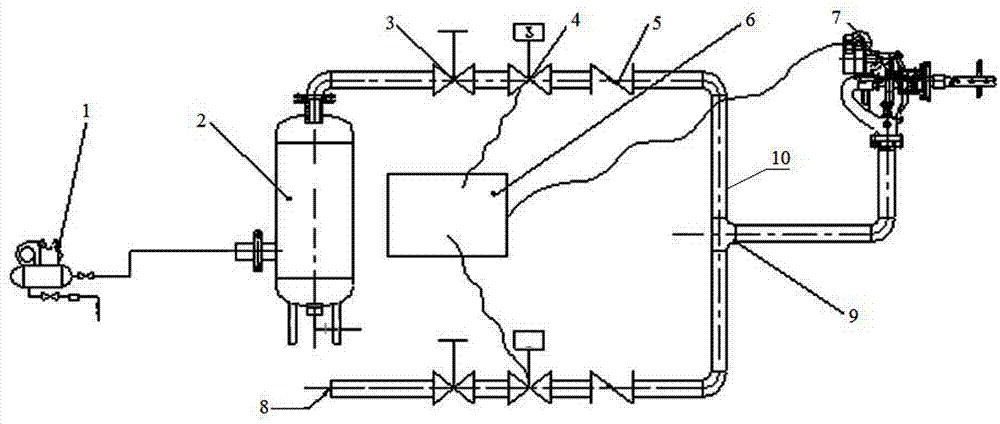

[0019] Embodiment 1: A complete set of boiler automatic dust removal equipment mentioned in the present invention, including an air compressor 1, a compressed air storage tank 2, a stop valve 3, a solenoid valve 4, a one-way valve 5, an automatic control system 6, a rotary blower Ash container 7, steam pipeline 8, tee pipe 9, air pipeline 10, air compressor 1 is connected to the inlet of compressed air storage tank 2, and the outlet of compressed air storage tank 2 passes through stop valve 3, solenoid valve 4, one-way The valve 5 is connected to the air pipeline 10, the solenoid valve 4 and the one-way valve 5 are controlled by the automatic control system 6, the rotary soot blower 7 is connected to the air pipeline 10 and the steam pipeline 8 through the three-way pipe 9, and the rotary soot blower The outlet of the device 7 is connected to the convection cavity 11, the convection cavity 11 has a conical structure, and the interior of the convection cavity 11 is provided with...

Embodiment 2

[0020] Embodiment 2: A complete set of boiler automatic dust removal equipment mentioned in the present invention, including an air compressor 1, a compressed air storage tank 2, a stop valve 3, a solenoid valve 4, a one-way valve 5, an automatic control system 6, a rotary blower Ash container 7, steam pipeline 8, tee pipe 9, air pipeline 10, air compressor 1 is connected to the inlet of compressed air storage tank 2, and the outlet of compressed air storage tank 2 passes through stop valve 3, solenoid valve 4, one-way The valve 5 is connected to the air pipeline 10, the solenoid valve 4 and the one-way valve 5 are controlled by the automatic control system 6, the rotary soot blower 7 is connected to the air pipeline 10 and the steam pipeline 8 through the three-way pipe 9, and the rotary soot blower The outlet of the device 7 is connected to the convection cavity 11, the convection cavity 11 has a conical structure, and the interior of the convection cavity 11 is provided with...

Embodiment 3

[0021]Embodiment 3: A complete set of boiler automatic dust removal equipment mentioned in the present invention, including an air compressor 1, a compressed air storage tank 2, a stop valve 3, a solenoid valve 4, a one-way valve 5, an automatic control system 6, a rotary blower Ash container 7, steam pipeline 8, tee pipe 9, air pipeline 10, air compressor 1 is connected to the inlet of compressed air storage tank 2, and the outlet of compressed air storage tank 2 passes through stop valve 3, solenoid valve 4, one-way The valve 5 is connected to the air pipeline 10, the solenoid valve 4 and the one-way valve 5 are controlled by the automatic control system 6, the rotary soot blower 7 is connected to the air pipeline 10 and the steam pipeline 8 through the three-way pipe 9, and the rotary soot blower The outlet of the device 7 is connected to the convection cavity 11, the convection cavity 11 has a conical structure, and the interior of the convection cavity 11 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com