Miniature solid mode locked laser

A mode-locked laser and solid-state technology, used in lasers, laser components, phonon exciters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

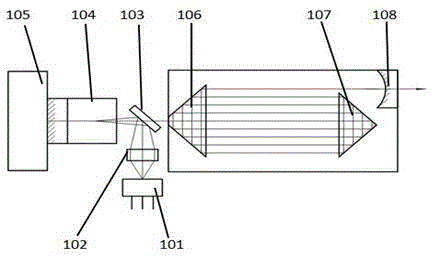

[0012] Embodiment one: the overall device such as figure 1 As shown, the light emitted by the pump source 101 passes through the focusing lens 102, and then enters the laser crystal 104 through the reflector 103. After the saturable absorber enters the pair of right-angle prisms 106 and 107, it reflects back and forth between the two right-angle prisms to increase the cavity length. Laser output. The right-angled side surfaces of the right-angle prism pair are also plated with a chirped film layer, which can play a role of dispersion compensation for the components in the cavity.

Embodiment approach 2

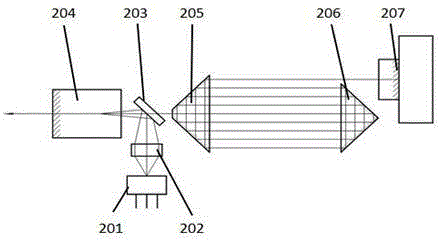

[0013] Embodiment two: the overall device such as figure 2 As shown, the light emitted by the pump source 201 passes through the focusing lens 202, and then enters the laser crystal 204 through the reflector 203. After being reflected by 204, the light enters the pair of right-angle prisms 205 and 206, and is reflected back and forth between the two right-angle prisms. 207 is a semiconductor saturable absorption mirror, coated with a high-reflection film for output laser as a front cavity mirror, and the laser passes through the semiconductor saturable absorption mirror. The original path is returned to output from the end face of the laser crystal.

Embodiment approach 3

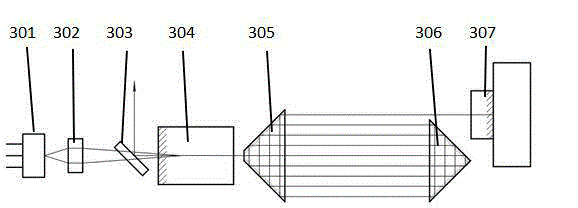

[0014] Embodiment three: the overall device such as image 3 As shown, compared with the second embodiment, the whole device is arranged on the same straight line, the light emitted by the pump source 301 passes through the focusing lens 302, and is focused to the laser crystal 304, and the end surface of the laser crystal is coated with a pump light high reflection film And the output laser anti-reflection film is used as the rear cavity mirror of the resonator, enters the pair of right-angle prisms 305 and 306, and reflects back and forth between the two right-angle prisms, 307 is a semiconductor saturable absorption mirror, and the high-reflection film coated with the output laser is used as the front cavity mirror. After the laser passes through the semiconductor saturable absorber mirror, it returns to the original path and is output from the reflector 303 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com