Ground-contour-following circular disc elastic claw pickup

A pick-up and spring-tooth technology, which is applied in the field of ground imitation disc spring-tooth pickers, can solve the problems of unimproved operation efficiency, deterioration of dynamic performance, and short service life of the whole machine, so as to improve the pick-up efficiency, Simple structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

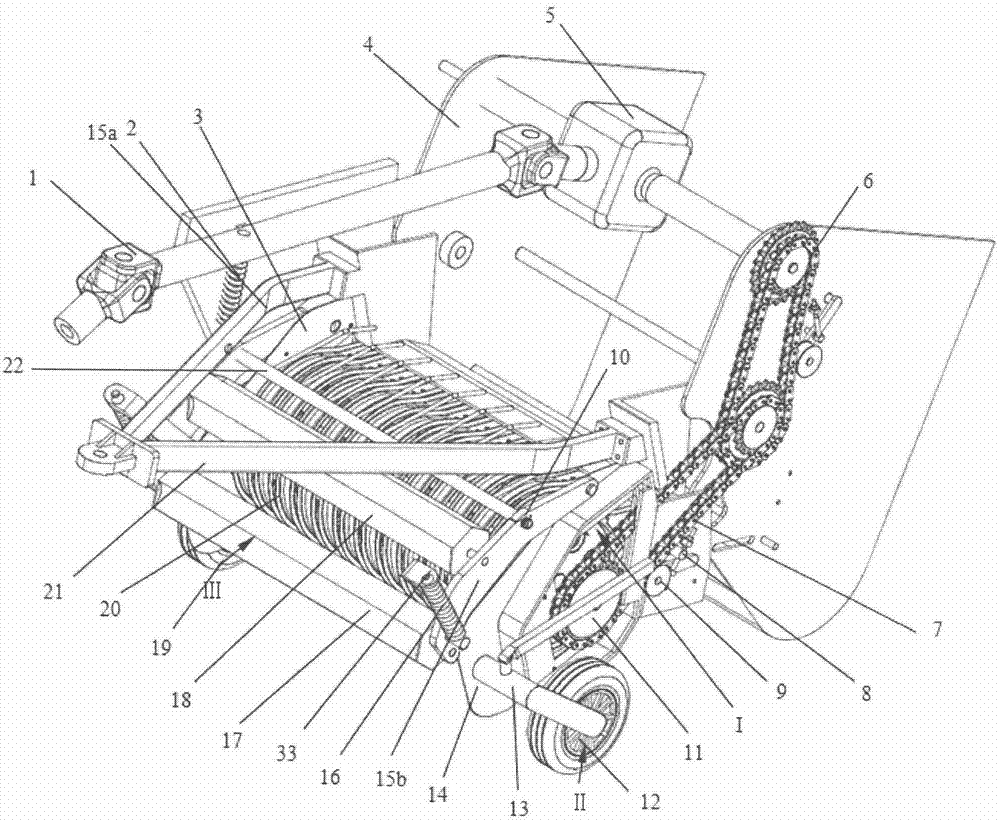

[0019] Such as figure 1 As shown, when the baler is working, it is connected with the tractor through the traction frame 21, and the power output shaft of the tractor is connected with the universal joint transmission 1 of the baler, and then the power is distributed to each working part through the transfer case 5. In this example, the power is transmitted to the pickup main shaft drive sprocket 11 through the primary chain drive 6 and the secondary chain drive 7 . Secondary chain transmission 7 adopts tensioning wheel 9 to carry out chain tensioning. The pick-up main shaft 27 is fixed with the pick-up main shaft drive sprocket 11.

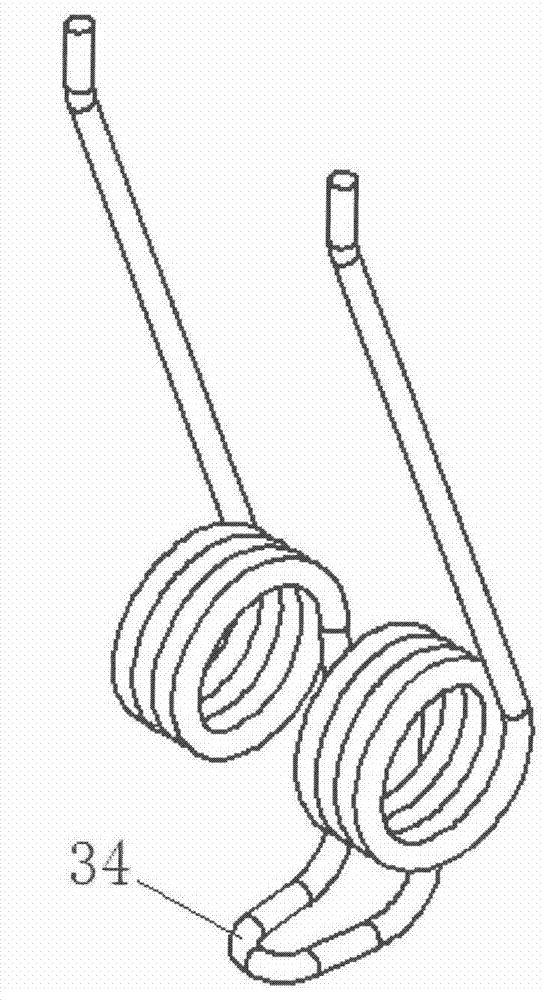

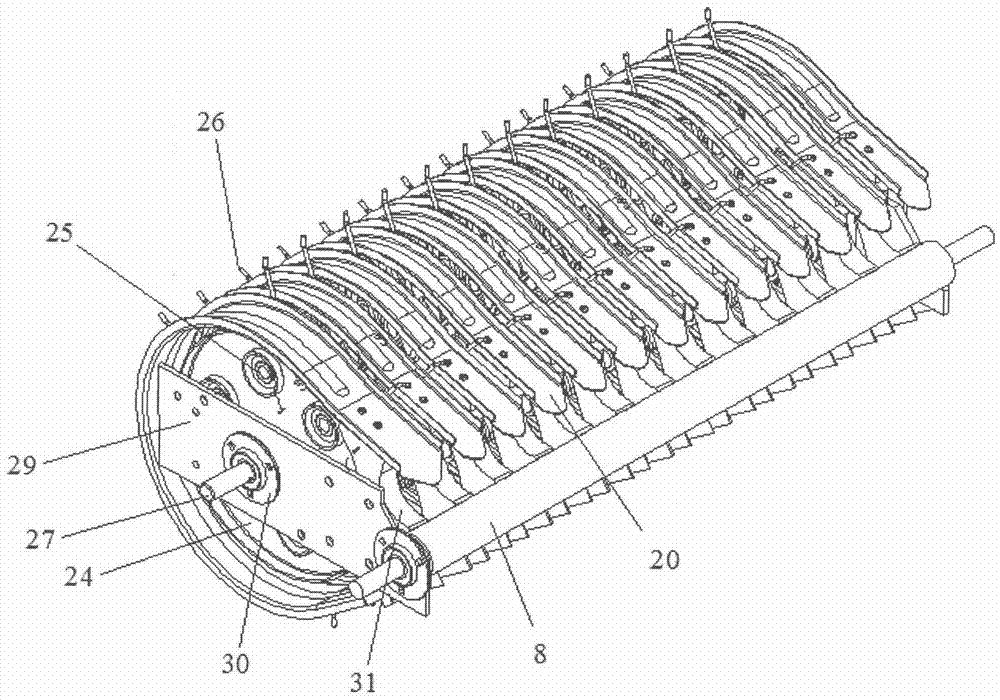

[0020] Such as Figure 2 to Figure 5 Shown, spring tooth cylinder 1 is made up of left and right drive disc 23,24, spring tooth bar 25, spring tooth 26 and curved dividing plate 20. The pick-up main shaft 27 is hinged on the left and right connecting plates 28, 29 through bearing seats, the left and right connecting plates 28, 29 are consolida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com