Method and device for recycling scrap iron of tapping machines

A technology of tapping machine and iron filings, applied in the field of machining and manufacturing, can solve the problems of splashing iron filings, unfavorable iron filings recovery, hidden dangers to the operators of the tapping machine, etc. The effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

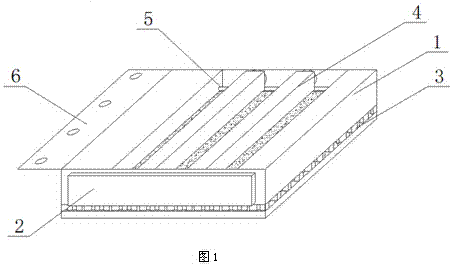

[0033] The main structure of this embodiment, such as figure 1 As shown, a device for recovering iron filings from a tapping machine includes an operating table 1, the middle part of which is a groove, and at least two vertically arranged and parallel support rods 4 are arranged in the groove. The lower part of the frame bar 4 is provided with a sieve layer 2, and the lower part of the sieve layer 2 is a magnetic layer 3 nested in the operating table 1, and the outer edge of the upper part of the operating table 1 is also provided with a fixed mounting plate 6; Also be provided with two transverse slide shafts 5, the two ends of frame bar 4 are all provided with pulleys matching with slide shafts, and described frame bar 4 is erected on the slide shaft 5 in the groove.

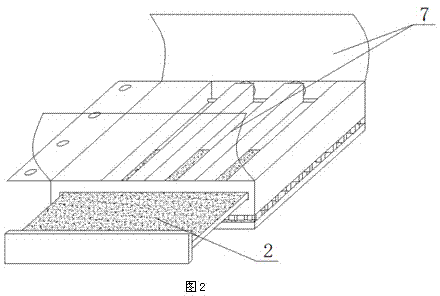

[0034] where, if figure 2 As shown, the console 1 is provided with a baffle plate 7 on both adjacent sides of the fixed mounting plate 6, the baffle plate 7 is a transparent plastic plate extending upward, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com