Horizontal sealing ironing knife device and its control method

A knife device, horizontal sealing technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low plastic film hot sealing efficiency and high defective rate, and achieve overall operating efficiency, reduce volume, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

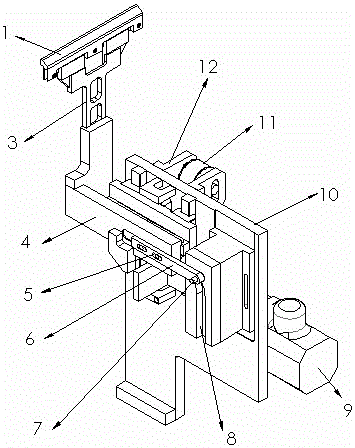

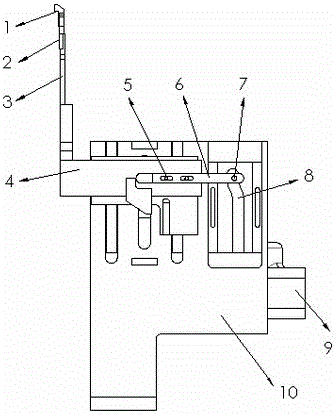

[0031] Such as figure 1 , 2 The horizontal sealing ironing knife device has a mounting bracket 10, and a servo motor 9 fixedly connected to the mounting bracket 10, a vertical rail 12 and a waist-shaped groove 8; the servo motor 9 provides power for the device.

[0032] Vertical track 12 is movably connected with horizontal track 4 which can move up and down along vertical track 12; The other end of the rigid knife arm 3 is connected to a horizontally arranged horizontal sealing ironing knife 1, and a heat shield 2 for heat insulation is connected between the rigid knife arm 3 and the horizontal sealing ironing knife 1.

[0033] The other end of the connecting rod 6 is connected with a crank 7 integrally made of polytetrafluoroethylene plastic, and the crank 7 is slidably connected with the waist-shaped groove 8 and can move along the waist-shaped groove 8 .

[0034] The lower section of the waist-shaped groove 8 is a vertical straight groove, and the upper section is an arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com