Low-pressure variation ethylene acrylate rubber material resistant to ultra-low temperature and high-temperature oil, and preparation method thereof

A technology for changing ethylene acrylate and rubber materials, which is applied in the field of low pressure changing ethylene acrylate rubber material and its preparation, can solve the problems of high oil resistance, can only reach -30--35 ℃, oil resistance is reduced, etc. The effect of good low temperature performance, reducing processing cost and improving low temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

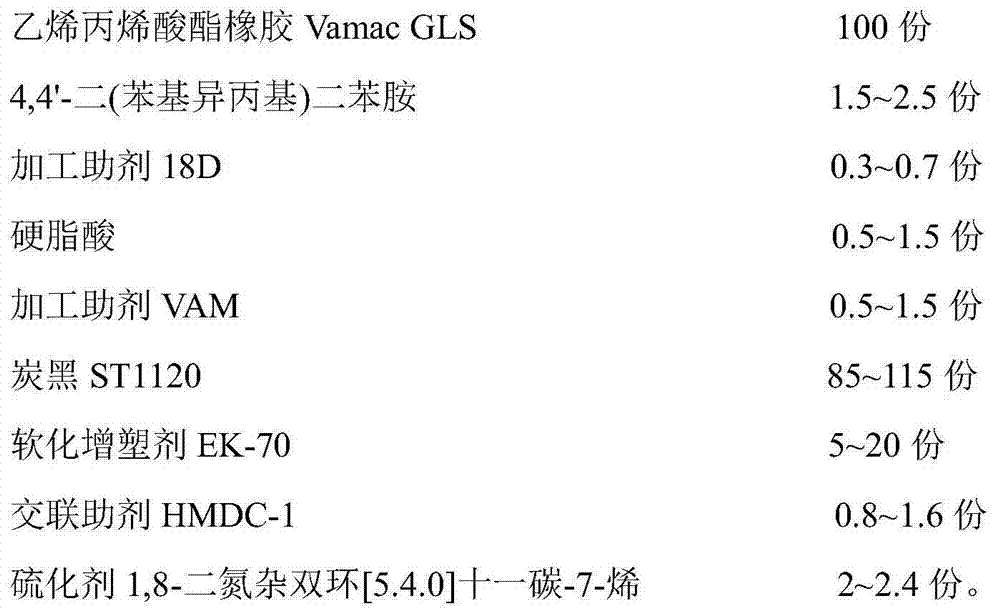

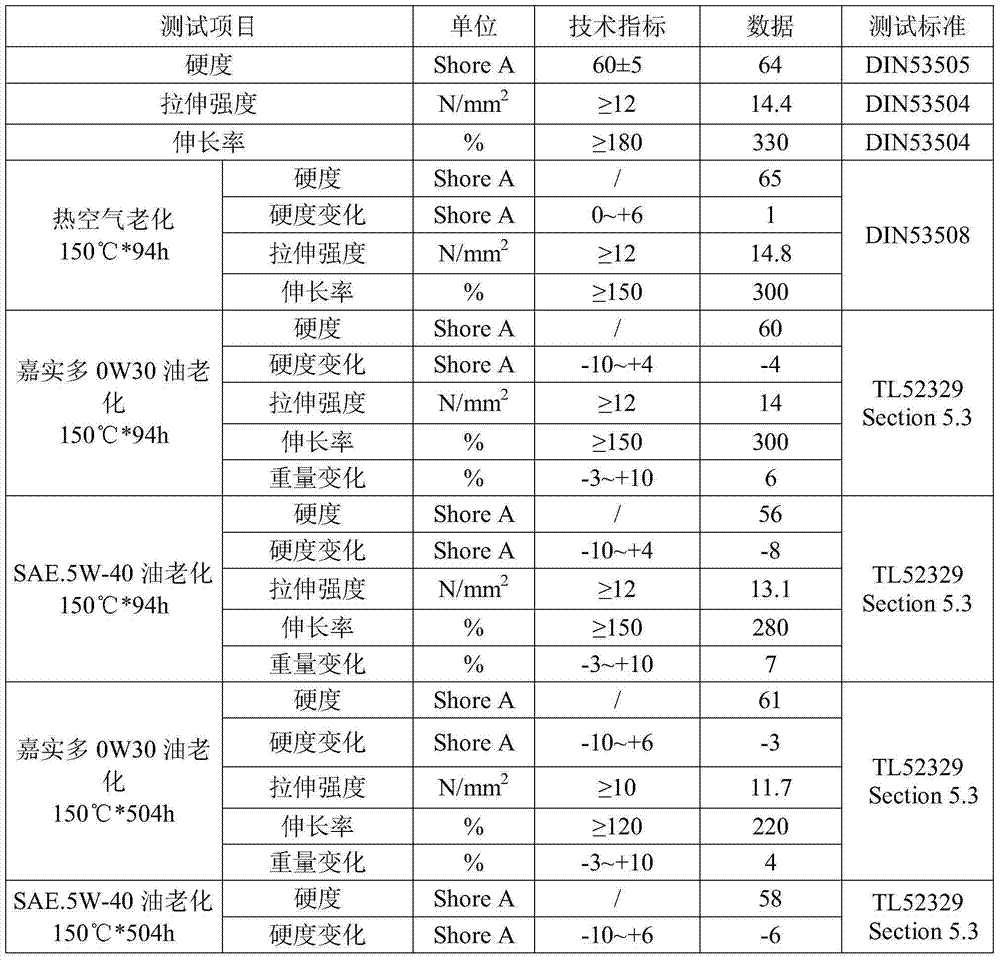

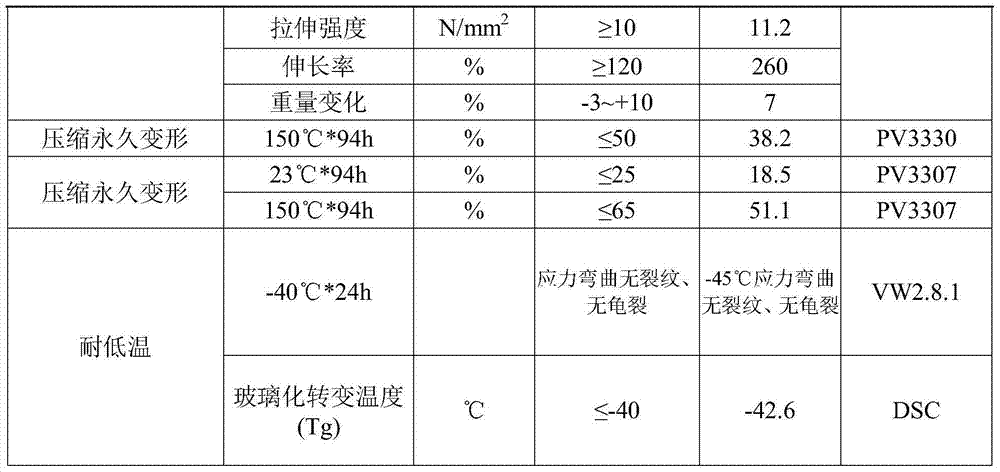

[0026] A low-pressure variable ethylene acrylate rubber material resistant to ultra-low temperature and high temperature oil in this embodiment, its mass ratio is as follows: 100 parts of ethylene acrylate rubber, 4,4'-bis(phenylisopropyl)diphenylamine 2 0.5 parts of processing aid 18D, 1 part of stearic acid, 1 part of processing aid VAM, 100 parts of carbon black ST1120, 12.5 parts of softening plasticizer EK-70, 11.2 parts of crosslinking aid HMDC-1,8 vulcanizing agent -2 parts of diazabicyclo[5.4.0]undec-7-ene.

[0027] Acrylate raw rubber is the Vamac GLS ethylene acrylate rubber that U.S. DuPont Company produces in the present embodiment; The supplier of carbon black ST1120 is Shanghai Eichuang Company; Stearic acid is produced by Malaysia Southern Oil Company; 4,4' bis( Phenylisopropyl)diphenylamine is anti-aging agent 445 (CAS No.: 10081-67-1) produced by Jiangsu Huada Chemical Group Co., Ltd.; processing aid VAM (CAS No.: 63231-60-7), processing aid The supplier of 1...

Embodiment 2

[0038] A low-pressure variable ethylene acrylate rubber material resistant to ultra-low temperature and high temperature oil in this embodiment, its mass ratio is as follows: 100 parts of ethylene acrylate rubber Vamac GLS, 4,4'-bis(phenylisopropyl) di 1.5 parts of aniline, 0.7 parts of processing aid 18D, 0.5 parts of stearic acid, 1.5 parts of processing aid VAM, 5 parts of carbon black ST112085 parts, softening plasticizer EK-705 parts, crosslinking aid HMDC-10.8 parts, vulcanizing agent 1 , 2.2 parts of 8-diazabicyclo[5.4.0]undec-7-ene.

[0039] The source of each component raw material of this embodiment is identical with embodiment 1.

[0040] The process of preparing low-pressure variable ethylene acrylate rubber material resistant to ultra-low temperature and high-temperature oil in this embodiment is as follows:

[0041] Step 1. Master batch mixing: According to the above formula, prepare materials, and send the raw materials except the vulcanizing agent 1,8-diazabic...

Embodiment 3

[0051] A low-pressure variable ethylene acrylate rubber material resistant to ultra-low temperature and high temperature oil in this embodiment, its mass ratio is as follows: 100 parts of ethylene acrylate rubber Vamac GLS, 4,4'-bis(phenylisopropyl) di 2.5 parts of aniline, 0.3 parts of processing aid 18D, 1.5 parts of stearic acid, 0.5 parts of processing aid VAM, 15 parts of carbon black ST1120115 parts, softening plasticizer EK-7020 parts, crosslinking aid HMDC-11.6 parts, vulcanizing agent 1 , 2.4 parts of 8-diazabicyclo[5.4.0]undec-7-ene.

[0052] The source of each component raw material of this embodiment is identical with embodiment 1.

[0053] The process of preparing low-pressure variable ethylene acrylate rubber material resistant to ultra-low temperature and high-temperature oil in this embodiment is as follows:

[0054] Step 1. Master batch mixing: According to the above formula, prepare materials, and send the raw materials except the vulcanizing agent 1,8-diaza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com