Large-sized deformed bar and manufacturing method thereof

A manufacturing method and large-scale technology, applied in the direction of building structure, structural elements, building components, etc., can solve problems such as unfavorable earthquake resistance, unfavorable cost saving, increase of construction project weight, etc., to improve mechanical strength and corrosion resistance, improve Surface quality, the effect of improving drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

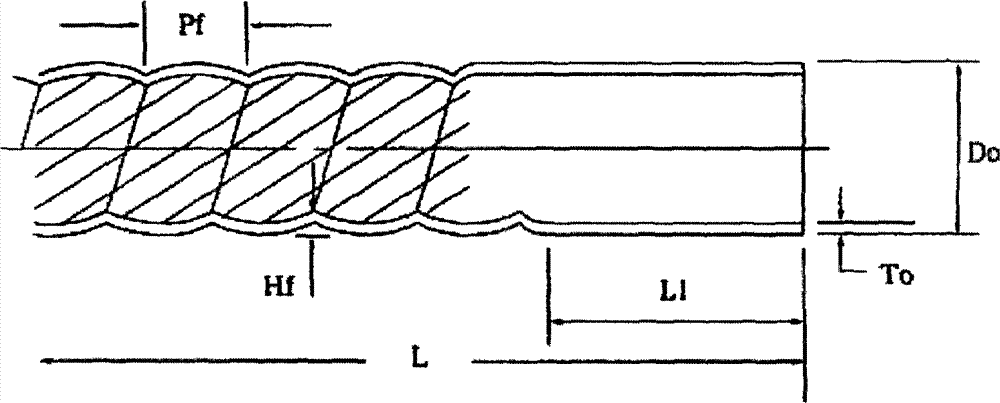

[0023] Such as Figure 1-2 Shown, the large size special-shaped steel bar of the present invention comprises:

[0024] A bare wall section, the bare wall section has two sections, which are respectively arranged at both ends of the large-size special-shaped steel bar;

[0025] A corrugated section, the corrugated section is arranged in the middle of the large-size special-shaped steel bar, and the two ends of the corrugated section are respectively connected with the smooth wall sections located at both ends; the shape of the corrugated section is a spiral waveform.

[0026] Further, the large-scale special-shaped steel bar is a hollow structure, and the wall thickness T of the large-scale special-shaped steel bar is 0 is 3mm, the diameter D of the light wall section of the large-scale special-shaped steel bar 0 20mm, and the diameter of the smooth wall section of the large-scale special-shaped steel bar is equal to the diameter of the waveform section; the total length L of...

Embodiment 2

[0038] Such as Figure 1-2 As shown, the large-scale special-shaped steel bars include:

[0039] A bare wall section, the bare wall section has two sections, which are respectively arranged at both ends of the large-size special-shaped steel bar;

[0040] A corrugated section, the corrugated section is arranged in the middle of the large-size special-shaped steel bar, and the two ends of the corrugated section are respectively connected with the smooth wall sections located at both ends; the shape of the corrugated section is a spiral waveform.

[0041] Further, the large-scale special-shaped steel bar is a hollow structure, and the wall thickness T of the large-scale special-shaped steel bar is 0 is 6mm, the diameter D of the light wall section of the large-scale special-shaped steel bar 0 40mm, and the diameter of the smooth wall section of the large-scale special-shaped steel bar is equal to the diameter of the waveform section; the total length L of the large-scale speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com